This file is a merged representation of a subset of the codebase, containing specifically included files, combined into a single document by Repomix.

This section contains a summary of this file.

This file contains a packed representation of the entire repository's contents.

It is designed to be easily consumable by AI systems for analysis, code review,

or other automated processes.

The content is organized as follows:

1. This summary section

2. Repository information

3. Directory structure

4. Repository files (if enabled)

5. Multiple file entries, each consisting of:

- File path as an attribute

- Full contents of the file

- This file should be treated as read-only. Any changes should be made to the

original repository files, not this packed version.

- When processing this file, use the file path to distinguish

between different files in the repository.

- Be aware that this file may contain sensitive information. Handle it with

the same level of security as you would the original repository.

- Some files may have been excluded based on .gitignore rules and Repomix's configuration

- Binary files are not included in this packed representation. Please refer to the Repository Structure section for a complete list of file paths, including binary files

- Only files matching these patterns are included: **/*.md, **/*.mdx

- Files matching patterns in .gitignore are excluded

- Files matching default ignore patterns are excluded

- Files are sorted by Git change count (files with more changes are at the bottom)

docs/

advanced/

ai-context.mdx

local-package-development.mdx

math-utils.mdx

simple-route-json.mdx

units.md

building-electronics/

designing-electronics-from-scratch.md

ordering-prototypes.mdx

what-are-electronics-made-of.mdx

command-line/

tsci-add.mdx

tsci-auth-print-token.md

tsci-build.md

tsci-dev.md

tsci-export.md

tsci-init.md

tsci-login.md

tsci-push.md

tsci-search.md

tsci-snapshot.md

contributing/

bounties-and-sponsorship.md

getting-started-as-a-contributor.md

making-lab-boards.mdx

overview-of-projects.md

package-dependencies-and-auto-updates.mdx

report-autorouter-bugs.md

the-contributor-handbook.md

elements/

analogsimulation.mdx

battery.mdx

board.mdx

breakout.mdx

breakoutpoint.mdx

cadassembly.mdx

cadmodel.mdx

capacitor.mdx

chip.mdx

crystal.mdx

cutout.mdx

diode.mdx

footprint.mdx

fuse.mdx

groundplane.mdx

group.mdx

hole.mdx

inductor.mdx

jumper.mdx

led.mdx

mosfet.mdx

net.mdx

netlabel.mdx

pcbnotedimension.mdx

pcbnoteline.mdx

pcbnotepath.mdx

pcbnoterect.mdx

pcbnotetext.mdx

pinheader.mdx

potentiometer.mdx

pushbutton.mdx

resistor.mdx

resonator.mdx

schematicarc.mdx

schematiccircle.mdx

schematicline.mdx

schematicpath.mdx

schematicrect.mdx

schematictext.mdx

solderjumper.mdx

subcircuit.mdx

switch.mdx

symbol.mdx

testpoint.mdx

trace.mdx

transistor.mdx

via.mdx

voltageprobe.mdx

voltagesource.mdx

footprints/

constraint.mdx

fabricationnoterect.mdx

fabricationnotetext.mdx

footprint-elements-vs-footprint-strings.mdx

footprinter-strings.mdx

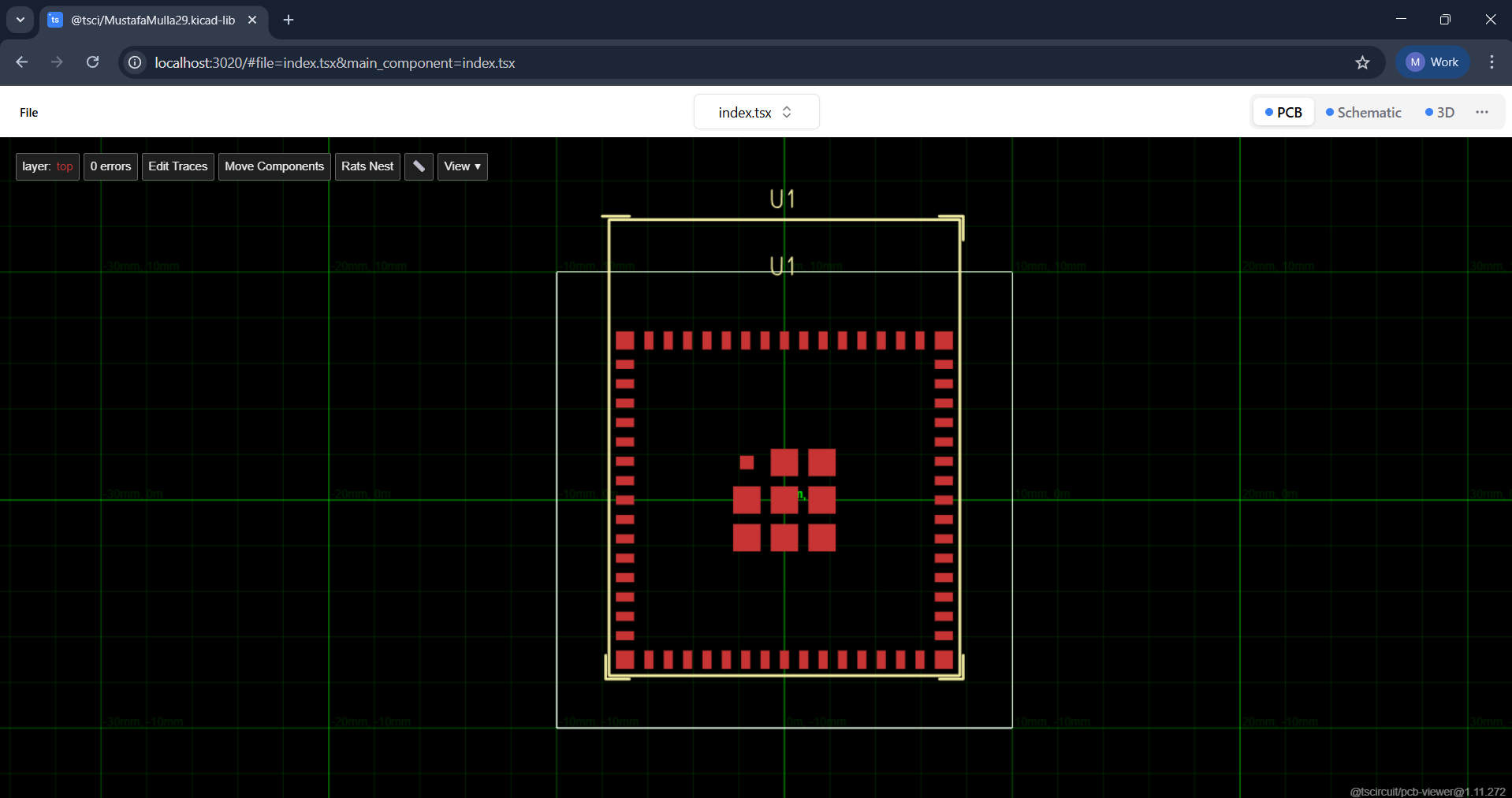

kicad-footprints.mdx

platedhole.mdx

silkscreencircle.mdx

silkscreenline.mdx

silkscreenpath.mdx

silkscreenrect.mdx

silkscreentext.mdx

smtpad.mdx

guides/

circuit-generation/

generating-circuit-boards-with-ai.mdx

importing-modules-and-chips/

importing-from-circuit-json.mdx

importing-from-jlcpcb.mdx

importing-from-kicad.md

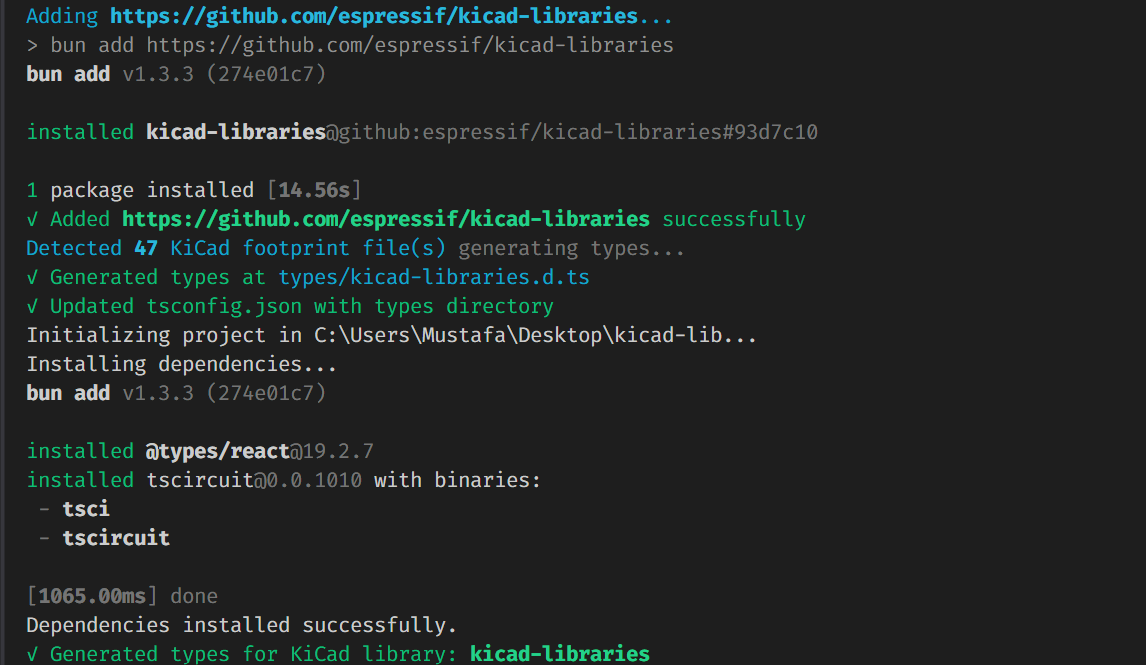

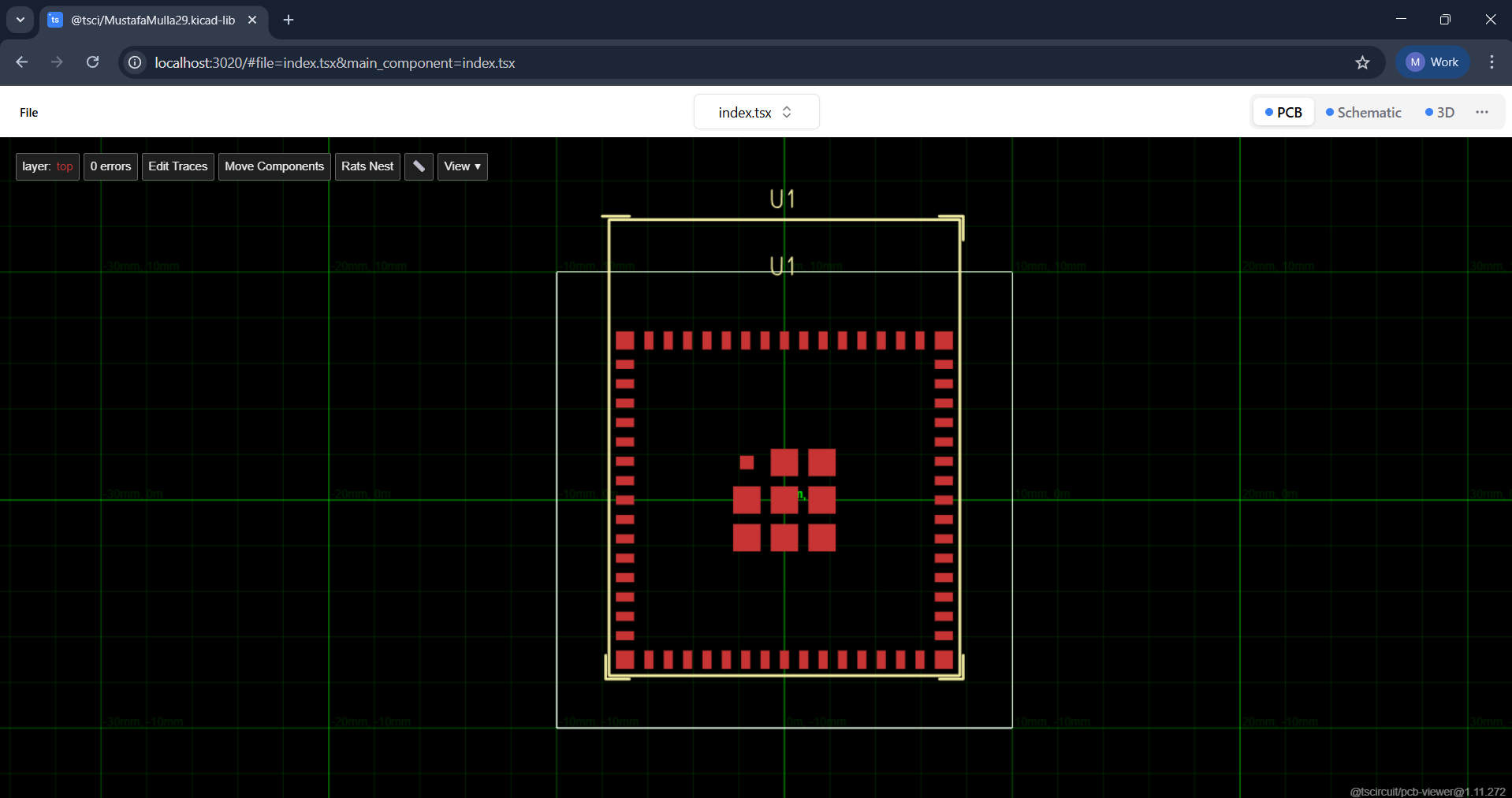

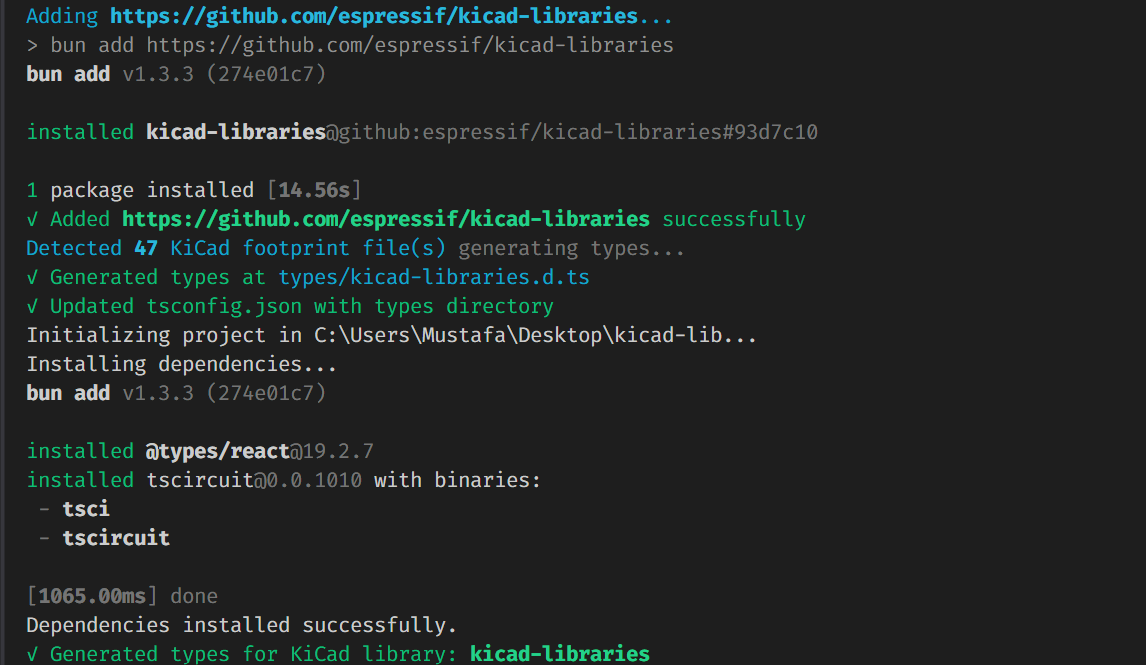

installing-kicad-libraries-from-github.md

kicad/

exporting-kicad-library.md

kicad-metadata.mdx

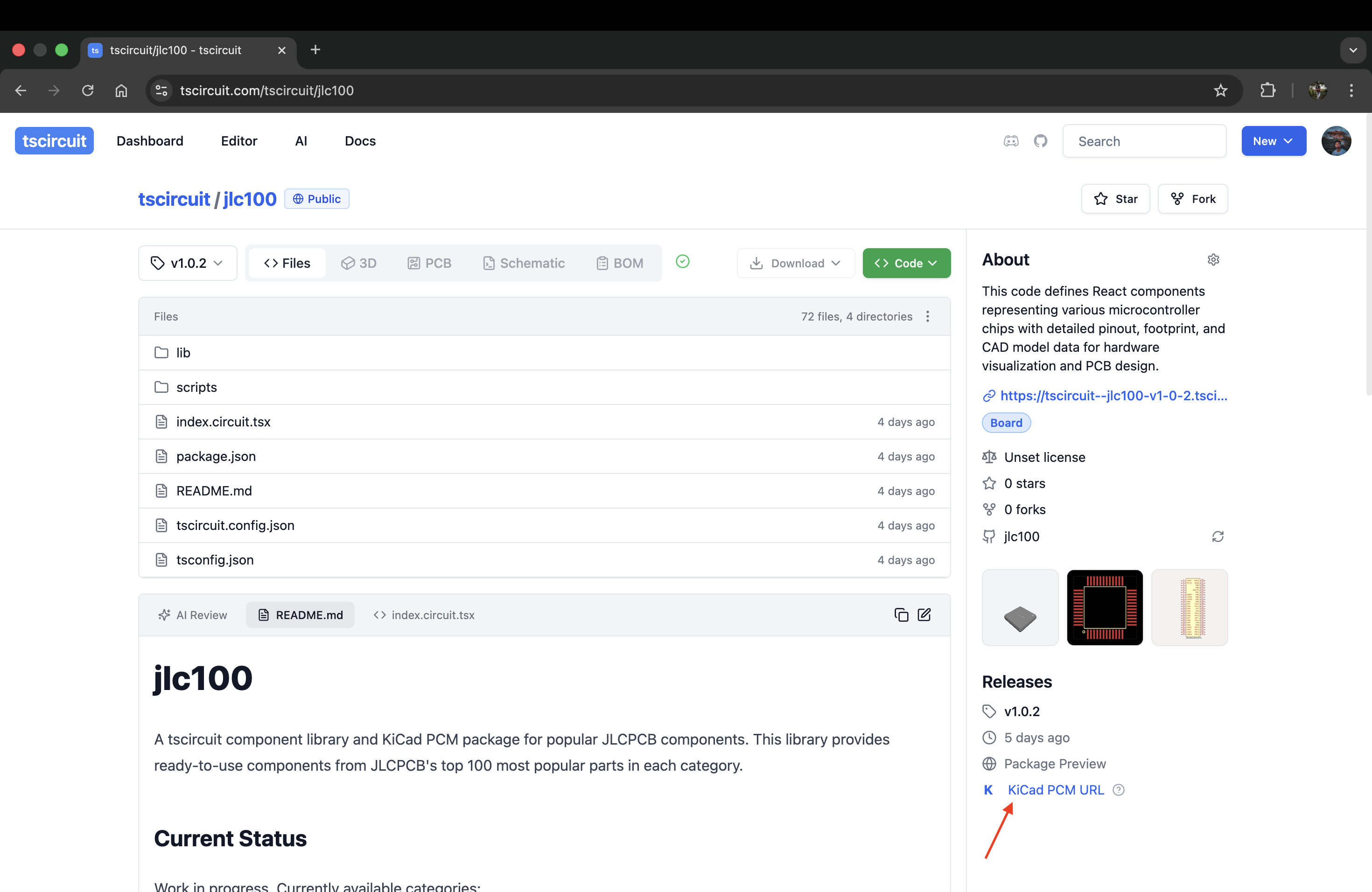

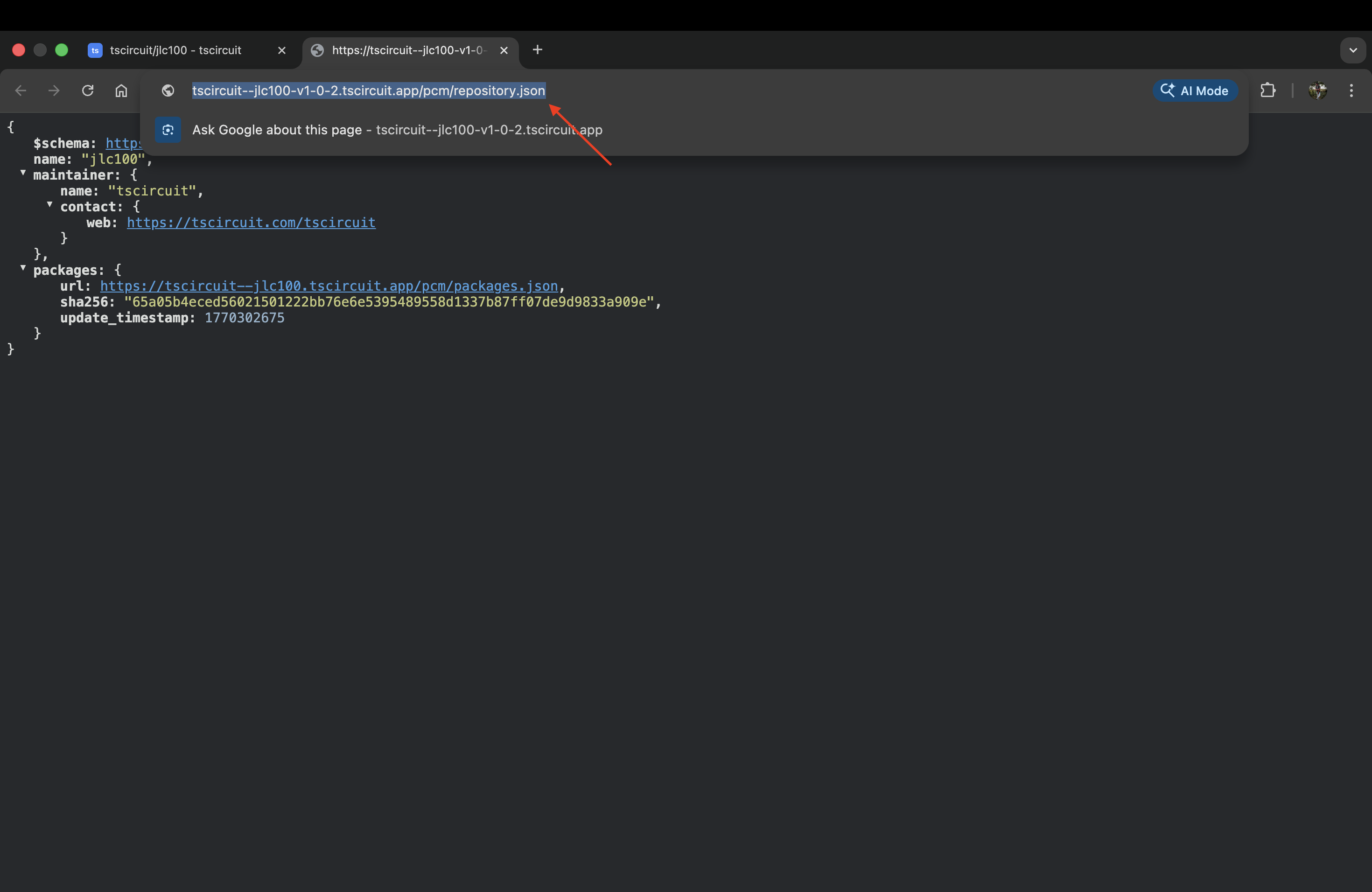

using-tscircuit-kicad-pcm-urls.md

running-tscircuit/

scripting/

measuring-circuit-size.mdx

building-static-sites-with-tsci.mdx

connecting-to-github.mdx

displaying-circuit-json-on-a-webpage.mdx

platform-configuration.md

programmatically-building-circuits.md

running-tscircuit-inside-an-iframe.mdx

running-tscircuit-standalone.mdx

using-tscircuit-without-react.mdx

spice-simulation/

Diodes/

full-wave-rectifier.mdx

half-wave-rectifier.mdx

Passive Filters/

high-pass-filter.mdx

low-pass-filter.mdx

Power Converters/

boost-converter.mdx

Transistors/

transistor-switch-example.mdx

introduction.mdx

tscircuit-essentials/

automatic-pcb-layout.mdx

automatic-schematic-layout.mdx

biscuit-board-laser-ablation.mdx

configuring-chips.mdx

essential-elements.mdx

layout-properties.mdx

manual-edits.mdx

panelization.mdx

pcb-sx.mdx

pinout-svg.mdx

port-and-net-selectors.md

tscircuit-config.mdx

using-expressions.mdx

using-groups-for-pcb-layout.mdx

using-sel-references.mdx

typescript-guide/

using-react-context-to-avoid-prop-drilling.mdx

using-typescript-path-aliases.mdx

understanding-fabrication-files.md

intro/

installation.md

quickstart-ChatGPT.mdx

quickstart-cli.md

quickstart-web.md

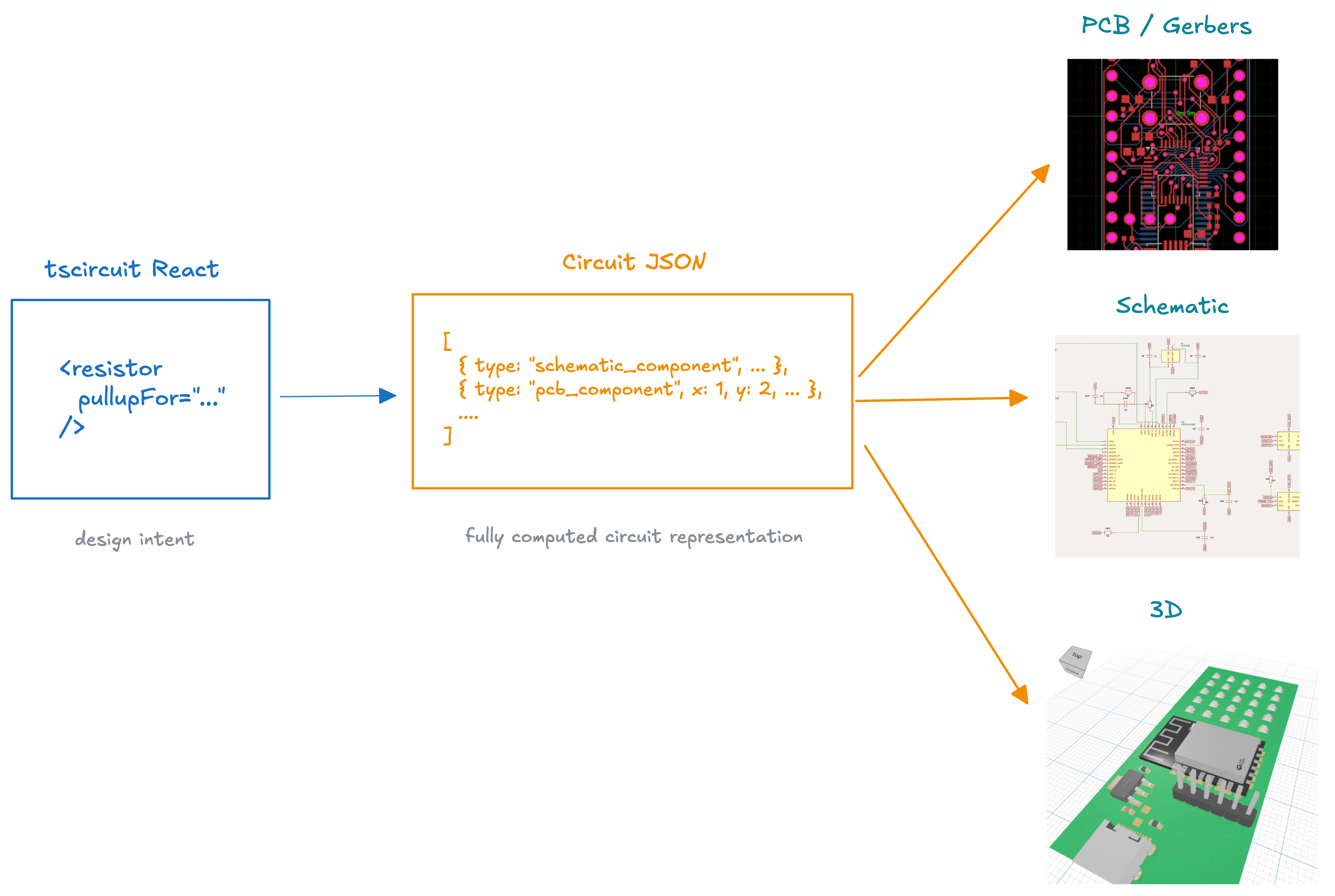

what-is-tscircuit.mdx

tutorials/

pi-hats/

simple-buzzer-hat.mdx

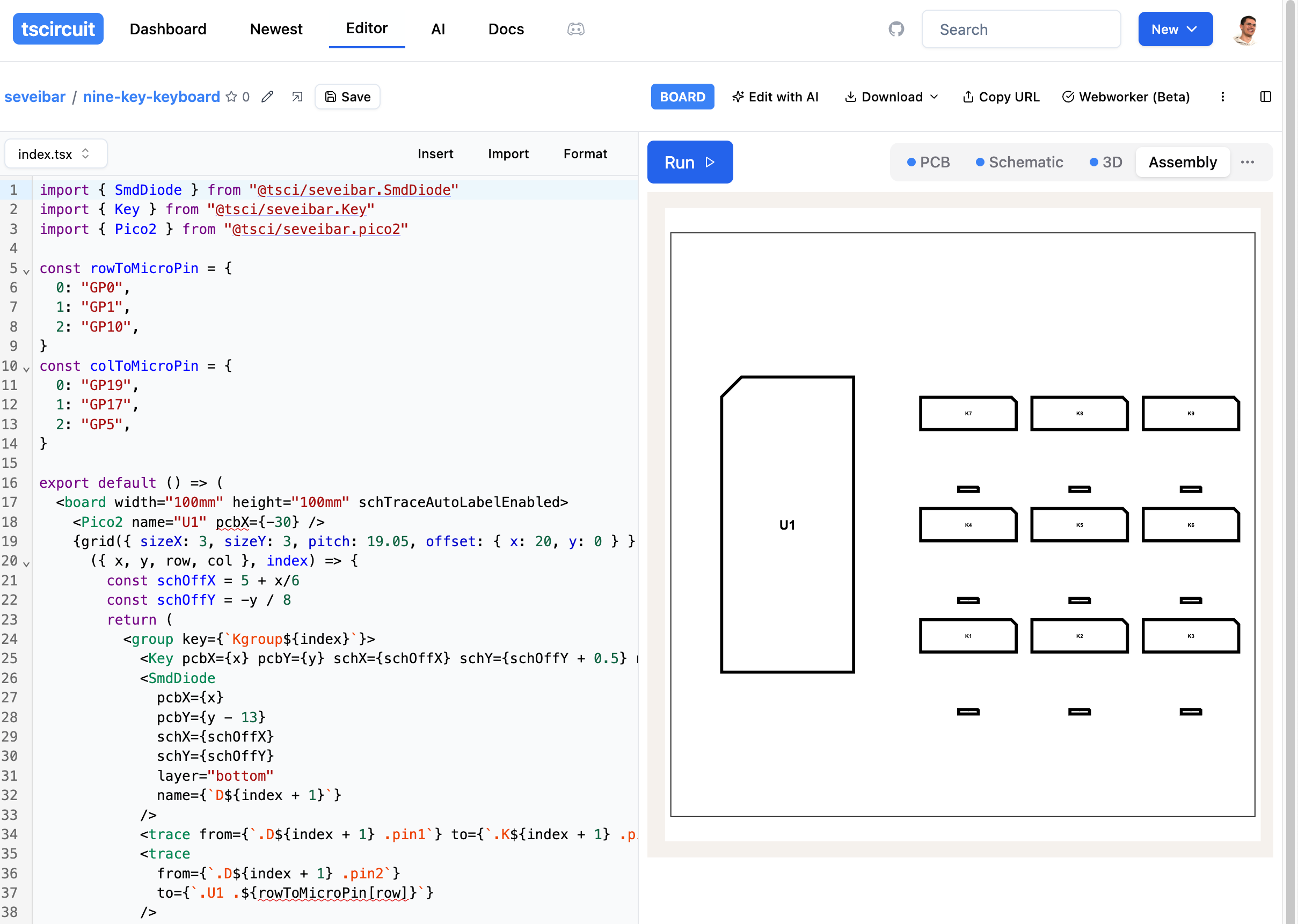

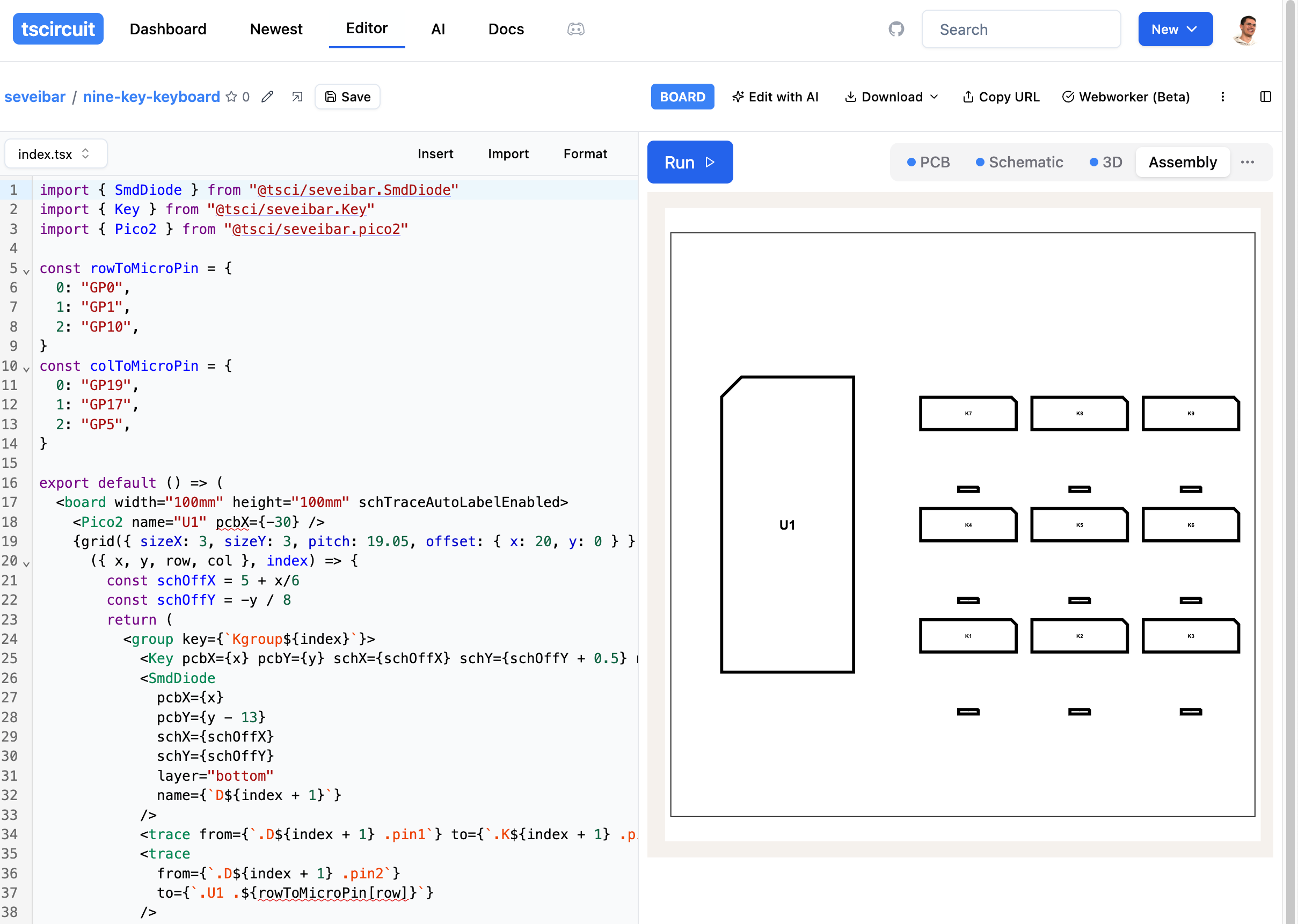

build-a-custom-keyboard-with-tscircuit.mdx

building-a-simple-usb-flashlight.mdx

building-led-matrix.mdx

web-apis/

autorouting-api.mdx

compile-api.md

datasheet-api.md

datasheet-sdk.md

image-generation-api.mdx

jlcsearch-api.md

ordering-api.mdx

the-registry-api.md

static/

templates/

AGENTS.md

CLAUDE.md

README.md

This section contains the contents of the repository's files.

---

title: AI Context

description: Learn how to use our AI context to help you design with tscircuit

---

import YouTubeEmbed from '../../src/components/YouTubeEmbed';

## Overview

You can drop our AI context into your Claude or OpenAI project by downloading

the [`ai.txt`](https://docs.tscircuit.com/ai.txt) file and dropping it into your project.

This will teach Claude and OpenAI about tscircuit so it can help you design

boards or access tricky or hidden pieces of the documentation!

You can also use [chat.tscircuit.com](https://chat.tscircuit.com) for a prebuilt version of the AI.

It contains live preview for a great development experience.

---

title: Local Package Development

description: Learn how to develop and test local packages with tsci dev using yalc and other linking tools

---

## Overview

When developing tscircuit projects, you may want to test changes to local packages without publishing them to npm. The `tsci dev` command automatically detects and uploads local packages, making local development seamless.

Currently supported methods:

- **yalc** - Recommended for most use cases

- **bun link** - Native Bun linking for Bun users

## What is Yalc?

[Yalc](https://github.com/wclr/yalc) is a tool for managing local package dependencies. It's a better alternative to `npm link` that creates a local package store and symlinks packages into your project's `node_modules`.

## Installation

First, install yalc globally:

```bash

npm install -g yalc

# or

bun install -g yalc

```

## Basic Workflow

### 1. Build and Publish Your Local Package

In the package you're developing `@/` (e.g., `@tscircuit/pico`):

```bash

cd path/to/your/local/package

# Build the package first

bun run build

# or npm run build

# Then publish to yalc

yalc publish

```

This builds the package and publishes the distribution files to your local yalc store.

**Note**: You must build the package before publishing with yalc, as it publishes the compiled output (typically in `dist/` or `lib/`), not the source files.

### 2. Link the Package to Your Project

In your tscircuit project:

```bash

cd path/to/your/tscircuit-project

yalc add @tscircuit/pico

```

This will:

- Add the package to your `node_modules`

- Update your `package.json` with a `file:.yalc/@tscircuit/pico` reference

- Create a `.yalc` directory with the package contents

### 3. Start Development

Run the dev server as usual:

```bash

tsci dev index.circuit.tsx

```

The dev server will automatically detect that `@tscircuit/pico` is a local package (via the `file:.yalc/` reference) and upload it along with your component files.

### 4. Update Your Local Package

When you make changes to your local package:

```bash

# In the local package directory

bun run build # Rebuild with your changes

yalc push # Push updates to all linked projects

```

This will rebuild and update all linked projects. You may need to restart `tsci dev` to pick up the changes.

## How It Works

The `tsci dev` command automatically uploads packages from `node_modules` **only if** they meet these criteria:

1. The package is referenced in `package.json` with a `file:.yalc/` path

2. The package exists in your `node_modules` directory

Regular npm packages (like `react`, `lodash`, etc.) are **not** uploaded to keep bundle sizes small and development fast.

## Example

Here's a complete example of developing a custom component library:

**Your local library** (`my-components`):

```tsx

// my-components/src/index.ts

export const MyCustomChip = (props: any) => {

return

}

```

**Publish it locally**:

```bash

bun run build

yalc publish

```

**Use it in your project**:

```bash

cd my-tscircuit-project

yalc add my-components

```

**Your component**:

```tsx

// circuit.tsx

import { MyCustomChip } from "my-components"

export default () => (

)

```

**Start dev server**:

```bash

tsci dev circuit.tsx

```

Now both your component and the `my-components` package code will be uploaded to the dev server!

## Removing Yalc Packages

To remove a yalc package and restore the npm version:

```bash

yalc remove @tscircuit/pico

npm install @tscircuit/pico

```

Or remove all yalc packages:

```bash

yalc remove --all

```

## Tips

- Use `yalc push` instead of `yalc publish` when updating packages - it's faster and automatically updates linked projects

- The `.yalc` directory and `yalc.lock` file should be added to `.gitignore`

- Remember to test with the published npm version before releasing to ensure compatibility

## Using Bun Link

If you're using Bun as your package manager, you can use the native `bun link` command instead of yalc. This provides a simpler workflow for Bun users.

### Basic Workflow with Bun Link

#### 1. Link Your Local Package

In the package you're developing (e.g., `@tscircuit/pico`):

```bash

cd path/to/your/local/package

# Build the package first

bun run build

# Register it for linking

bun link

```

This registers the package globally, making it available for linking in other projects.

#### 2. Link the Package to Your Project

In your tscircuit project:

```bash

cd path/to/your/tscircuit-project

bun link @tscircuit/pico

```

This creates a symlink in your project's `node_modules` pointing to your local package.

#### 3. Start Development

Run the dev server as usual:

```bash

tsci dev index.circuit.tsx

```

The dev server will automatically detect that `@tscircuit/pico` is a local package (via the symlink) and upload it along with your component files.

#### 4. Update Your Local Package

When you make changes to your local package:

```bash

# In the local package directory

bun run build # Rebuild with your changes

```

Since `bun link` uses symlinks, the changes will be immediately available. You may need to restart `tsci dev` to pick up the changes.

### Unlinking Bun Packages

To remove a linked package:

```bash

# In your project

bun unlink @tscircuit/pico

```

To remove the global link registration:

```bash

# In the package directory

bun unlink

```

---

title: Math Utils

description: >-

The `@tscircuit/math-utils` package provides a set of utilities that are

commonly used in circuit design. The `@tscircuit/math-utils` package is

generally available in any platform that uses `tscircuit`.

---

## Overview

The `@tscircuit/math-utils` package provides a set of utilities that are

commonly used in circuit design. The `@tscircuit/math-utils` package is

generally available in any platform that uses `tscircuit`.

The source code for the `@tscircuit/math-utils` package [is available here](https://github.com/tscircuit/math-utils)

## `grid`

A utility function that generates a grid of cells with configurable dimensions, spacing, and positioning. Each cell contains its index, position (row/column), and coordinate points (center, top-left, bottom-right).

(

{gridCells.map((cell) => (

))}

)

`}

/>

## Grid Options

| Option | Description | Default |

| ------ | ----------- | ------- |

| `rows` | Number of rows in the generated grid. | Required |

| `cols` | Number of columns in the generated grid. | Required |

| `width` | Total width of the grid. When omitted, uses `cols * xSpacing`. | `cols * xSpacing` |

| `height` | Total height of the grid. When omitted, uses `rows * ySpacing`. | `rows * ySpacing` |

| `xSpacing` | Horizontal spacing between cells when `width` is not provided. | `1` |

| `ySpacing` | Vertical spacing between cells when `height` is not provided. | `1` |

| `offsetX` | Horizontal offset applied to every cell. | `0` |

| `offsetY` | Vertical offset applied to every cell. | `0` |

| `yDirection` | Sets positive Y direction: `"cartesian"` keeps positive-up, `"up-is-negative"` flips it. | `"cartesian"` |

| `centered` | Centers the grid around the origin when `true`. | `true` |

## Grid Cell Data

Each object returned by `grid` represents a cell with useful positional metadata:

| Property | Description |

| -------- | ----------- |

| `index` | Sequential identifier for the cell. |

| `row` / `col` | Grid coordinates of the cell starting from zero. |

| `center` | `{ x, y }` coordinates of the cell center. |

| `topLeft` | `{ x, y }` coordinates of the cell's top-left corner. |

| `bottomRight` | `{ x, y }` coordinates of the cell's bottom-right corner. |

---

title: Simple Route JSON

description: >-

Simple Route JSON (SRJ) is a lightweight, straightforward format designed to

describe a Printed Circuit Board (PCB) routing problem. It serves as a common

intermediary representation used by `tscircuit` autorouters, simplifying the

complex details often found in full PCB design files.

---

## Overview

Simple Route JSON (SRJ) is a lightweight, straightforward format designed to describe a Printed Circuit Board (PCB) routing problem. It serves as a common intermediary representation used by [`tscircuit` autorouters](https://github.com/tscircuit/unravel-autorouter), simplifying the complex details often found in full PCB design files.

The primary goal of SRJ is to provide only the essential information required for a routing algorithm:

1. Where routing is allowed (layers, board boundaries).

2. Where routing is forbidden (obstacles, keep-out areas).

3. What needs to be connected (nets and their associated pins/pads).

4. Basic routing constraints (minimum trace width).

SRJ can be directly generated from more comprehensive formats like [Circuit JSON](https://circuitjson.com), stripping away details irrelevant to the core routing task (e.g., specific component models, schematic information beyond connectivity). It shares conceptual similarities with the industry-standard [Specctra DSN (Design)](https://github.com/tscircuit/dsn-converter) format, but aims for greater simplicity and modern JSON representation.

:::info

A formal specification with versioning is planned for the future. To stay updated on its release and other tscircuit developments, please subscribe to [the tscircuit newsletter](https://blog.tscircuit.com/).

:::

## Format Structure

A Simple Route JSON file is a single JSON object containing the definition of the board layout, obstacles, and connections needed for routing.

```typescript

export interface SimpleRouteJson {

/** The total number of conductive layers on the PCB. */

layerCount: number;

/** The default or minimum width for traces. Specific trace segments might override this if the format evolves, but currently used as a general guideline. Units are implicit (e.g., mm, inches) and must be consistent throughout the file. */

minTraceWidth: number;

/** An array of obstacles on the board, such as component pads, mounting holes, or keep-out areas. */

obstacles: Obstacle[];

/** An array defining the electrical connections (nets) that need to be routed. */

connections: Array;

/** The bounding box defining the extents of the routing area. */

bounds: { minX: number; maxX: number; minY: number; maxY: number };

/** [Optional] The routing solution provided by an autorouter. This array contains the actual paths of the traces. It is typically absent in the input file given to a router and present in the output file. */

traces?: SimplifiedPcbTrace[];

}

```

## Top-Level Properties

### `layerCount`

* **Type:** `number`

* **Description:** An integer specifying the total number of conductive layers available for routing on the PCB. Layers are typically identified by string names (e.g., `"top"`, `"inner1"`, `"bottom"`) within other parts of the format (like `obstacles` and `connections`). While `layerCount` provides the total number, the specific layer names used must be consistent throughout the file.

### `minTraceWidth`

* **Type:** `number`

* **Description:** Specifies the default or minimum trace width to be used by the autorouter. This acts as a global constraint. Future versions or specific router implementations might allow per-net or per-segment width rules, but this provides a baseline.

* **Units:** Units (e.g., millimeters, inches) are not explicitly defined by the format. It is crucial that the same unit system is used consistently for all dimensional values (`minTraceWidth`, `obstacles`, `bounds`, coordinates) within a single SRJ file. Millimeters (mm) are commonly used.

### `obstacles`

* **Type:** `Array`

* **Description:** An array containing objects that represent areas on the PCB where routing is either restricted or represents a connection point. Obstacles can be physical component pads, mounting holes, board edges defined as keep-outs, or explicit keep-out zones.

```typescript

export type Obstacle = {

/** The shape of the obstacle. Currently, only "rect" is standard. Oval shapes might be included in future revisions. */

type: "rect"; // NOTE: most datasets do not contain ovals

/** An array of layer names (strings) on which this obstacle exists. An obstacle can span multiple layers (e.g., a plated through-hole pad). */

layers: string[];

/** The center coordinates of the obstacle. */

center: { x: number; y: number };

/** The width of the rectangular obstacle. */

width: number;

/** The height of the rectangular obstacle. */

height: number;

/** An array of connection names (strings) that this obstacle is part of. If this obstacle is a pad for a net (e.g., "GND", "VCC"), the net name(s) will be listed here. If the array is empty, the obstacle is typically a keep-out area or an unconnected feature. */

connectedTo: string[];

};

```

* **`type`**: Defines the geometry. Currently `"rect"` is the standard.

* **`layers`**: Specifies which layer(s) the obstacle occupies. Important for multi-layer routing.

* **`center`, `width`, `height`**: Define the geometry and position of the rectangle. Units must be consistent with `minTraceWidth` and `bounds`.

* **`connectedTo`**: This critical field links obstacles (like pads) to the electrical nets defined in the `connections` array. If an obstacle represents a pin for the "VCC" net, `connectedTo` would contain `["VCC"]`.

### `connections`

* **Type:** `Array`

* **Description:** Defines the sets of points that need to be electrically connected. Each object in the array represents a single net (e.g., power, ground, signal).

```typescript

export interface SimpleRouteConnection {

/** The unique name of the connection or net (e.g., "GND", "VCC", "DATA0"). This name is referenced by Obstacle.connectedTo. */

name: string;

/** An array of points that must be connected together to form this net. Each point typically corresponds to the center of an obstacle (pad) belonging to this net. */

pointsToConnect: Array<{

/** The x-coordinate of the connection point. */

x: number;

/** The y-coordinate of the connection point. */

y: number;

/** The layer name (string) on which this connection point resides. */

layer: string;

}>;

}

```

* **`name`**: A unique string identifier for the net. This is used to link `Obstacle` objects (pads) to their respective nets.

* **`pointsToConnect`**: An array listing the specific locations (`x`, `y`, `layer`) that the router must connect. These points usually align with the `center` coordinates and `layers` of the corresponding `Obstacle` objects linked via the `name`.

### `bounds`

* **Type:** `object`

* **Description:** Defines the rectangular boundary of the area where routing is permitted. Traces should generally not extend beyond these limits.

* **Structure:**

* `minX`: The minimum x-coordinate of the routing area.

* `maxX`: The maximum x-coordinate of the routing area.

* `minY`: The minimum y-coordinate of the routing area.

* `maxY`: The maximum y-coordinate of the routing area.

* **Units:** Must be consistent with other dimensional values in the file.

### `traces` (Optional)

* **Type:** `Array`

* **Description:** This array represents the output of an autorouter – the actual geometric paths (traces and vias) that implement the required connections. It is typically **not present** in the input SRJ file given to the router.

* **Presence:** Included in the SRJ file *after* routing has been successfully completed.

```typescript

export type SimplifiedPcbTrace = {

/** Identifier indicating the object type. Always "pcb_trace". */

type: "pcb_trace";

/** A unique identifier for this specific trace path. */

pcb_trace_id: string;

/** [Optional] The name of the connection/net this trace belongs to. Links the solved route back to the SimpleRouteConnection definition. */

connection_name?: string;

/** An array defining the geometry of the trace path, composed of wire segments and vias. */

route: Array<

| {

/** Indicates a straight wire segment on a single layer. */

route_type: "wire";

/** The x-coordinate of the *end* point of the wire segment. */

x: number;

/** The y-coordinate of the *end* point of the wire segment. */

y: number;

/** The width of this wire segment. */

width: number;

/** The layer name (string) this wire segment is on. */

layer: string;

}

| {

/** Indicates a via connecting two layers. */

route_type: "via";

/** The x-coordinate of the via's center. */

x: number;

/** The y-coordinate of the via's center. */

y: number;

/** The layer name (string) the via transitions *to*. */

to_layer: string;

/** The layer name (string) the via transitions *from*. */

from_layer: string;

}

>;

};

```

* **`type`**: Always `"pcb_trace"`.

* **`pcb_trace_id`**: Unique ID for the trace.

* **`connection_name`**: Links trace to the net name from `connections`.

* **`route`**: An ordered array describing the path:

* **`wire`**: Represents a straight segment of copper trace. The segment runs from the end point of the previous element in the `route` array (or an initial connection point) to the specified `(x, y)` coordinate on the given `layer` with the specified `width`.

* **`via`**: Represents a vertical connection between layers at `(x, y)`, transitioning from `from_layer` to `to_layer`. Note that physical via characteristics (drill size, annular ring) are not detailed in this simplified format.

## Example

```json

{

"layerCount": 2,

"minTraceWidth": 0.15,

"obstacles": [

{

"type": "rect",

"layers": ["top"],

"center": { "x": 10, "y": 10 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["VCC"]

},

{

"type": "rect",

"layers": ["top"],

"center": { "x": 30, "y": 10 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["VCC"]

},

{

"type": "rect",

"layers": ["bottom"],

"center": { "x": 20, "y": 25 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["GND"]

},

{

"type": "rect",

"layers": ["bottom"],

"center": { "x": 40, "y": 25 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["GND"]

},

{

"type": "rect",

"layers": ["top", "bottom"], // Keepout on both layers

"center": { "x": 25, "y": 15 },

"width": 5,

"height": 3,

"connectedTo": [] // Empty means it's a keepout

}

],

"connections": [

{

"name": "VCC",

"pointsToConnect": [

{ "x": 10, "y": 10, "layer": "top" },

{ "x": 30, "y": 10, "layer": "top" }

]

},

{

"name": "GND",

"pointsToConnect": [

{ "x": 20, "y": 25, "layer": "bottom" },

{ "x": 40, "y": 25, "layer": "bottom" }

]

}

],

"bounds": {

"minX": 0,

"maxX": 50,

"minY": 0,

"maxY": 40

},

// --- TRACES SECTION (added by router) ---

"traces": [

{

"type": "pcb_trace",

"pcb_trace_id": "trace_vcc_1",

"connection_name": "VCC",

"route": [

{ "route_type": "wire", "x": 10, "y": 10, "width": 0.15, "layer": "top" }, // Start implicitly at first point

{ "route_type": "wire", "x": 20, "y": 5, "width": 0.15, "layer": "top" },

{ "route_type": "wire", "x": 30, "y": 10, "width": 0.15, "layer": "top" } // End at second point

]

},

{

"type": "pcb_trace",

"pcb_trace_id": "trace_gnd_1",

"connection_name": "GND",

"route": [

{ "route_type": "wire", "x": 20, "y": 25, "width": 0.15, "layer": "bottom" }, // Start implicitly at first point

// Example with a via

{ "route_type": "wire", "x": 30, "y": 25, "width": 0.15, "layer": "bottom" },

{ "route_type": "via", "x": 30, "y": 25, "from_layer": "bottom", "to_layer": "top" },

{ "route_type": "wire", "x": 30, "y": 20, "width": 0.15, "layer": "top" }, // Segment on top layer

{ "route_type": "via", "x": 30, "y": 20, "from_layer": "top", "to_layer": "bottom" },

{ "route_type": "wire", "x": 40, "y": 25, "width": 0.15, "layer": "bottom" } // End at second point

]

}

]

}

```

## Units and Coordinate System

The Simple Route JSON format does **not** enforce specific units (e.g., mm, mil, inches) or a coordinate system origin (e.g., top-left, bottom-left).

* **Consistency is Key:** All dimensional values (`minTraceWidth`, obstacle `width`/`height`, `bounds`, all `x`/`y` coordinates in `obstacles`, `connections`, and `traces`) within a single SRJ file **must** use the same units.

* **Common Practice:** Millimeters (mm) are frequently used.

* **Origin:** The coordinate system origin is typically assumed to be top-left or bottom-left, with X increasing to the right and Y increasing downwards (top-left) or upwards (bottom-left). Consistency within the file and between the SRJ generator and consumer (the autorouter) is essential.

## Relationship to Other Formats

* **Circuit JSON:** Simple Route JSON is a simplified derivative of Circuit JSON. Tools can convert Circuit JSON to SRJ by extracting layer stackup information, component pad locations and net assignments, board outlines, and any defined keep-out areas. Information not relevant to routing (e.g., schematic IDs, component values, 3D models) is omitted.

* **Specctra DSN:** SRJ serves a similar purpose to DSN files – describing a routing problem. However, SRJ uses a modern JSON structure, which is often easier to parse and generate in web-based and JavaScript/TypeScript environments compared to the text-based, keyword-driven DSN format. The `dsn-converter` tool ([link](https://github.com/tscircuit/dsn-converter)) can facilitate conversion between DSN and SRJ or similar formats.

## Usage

The primary use case for Simple Route JSON is as the input and output format for `tscircuit` autorouting tools.

1. **Input:** A PCB design tool or conversion script generates an SRJ file describing the board, obstacles, and connections. This file is fed into an autorouter.

2. **Output:** The autorouter processes the input SRJ, computes the trace paths, and outputs a new SRJ file that includes the original data plus the `traces` array detailing the solution.

3. **Post-processing:** The output SRJ (with traces) can then be converted back into a format compatible with PCB design software (like Circuit JSON, KiCad, Eagle, etc.) to integrate the routing solution into the full PCB design.

``````markdown

---

title: Simple Route JSON

---

## Overview

Simple Route JSON (SRJ) is a lightweight, straightforward format designed to describe a Printed Circuit Board (PCB) routing problem. It serves as a common intermediary representation used by `tscircuit` autorouters, simplifying the complex details often found in full PCB design files.

The primary goal of SRJ is to provide only the essential information required for a routing algorithm:

1. Where routing is allowed (layers, board boundaries).

2. Where routing is forbidden (obstacles, keep-out areas).

3. What needs to be connected (nets and their associated pins/pads).

4. Basic routing constraints (minimum trace width).

SRJ can be directly generated from more comprehensive formats like [Circuit JSON](https://circuitjson.com), stripping away details irrelevant to the core routing task (e.g., specific component models, schematic information beyond connectivity). It shares conceptual similarities with the industry-standard [Specctra DSN (Design)](https://github.com/tscircuit/dsn-converter) format, but aims for greater simplicity and modern JSON representation.

:::info

A formal specification with versioning is planned for the future. To stay updated on its release and other tscircuit developments, please subscribe to [the tscircuit newsletter](https://blog.tscircuit.com/).

:::

## Format Structure

A Simple Route JSON file is a single JSON object containing the definition of the board layout, obstacles, and connections needed for routing.

```typescript

export interface SimpleRouteJson {

/** The total number of conductive layers on the PCB. */

layerCount: number;

/** The default or minimum width for traces. Specific trace segments might override this if the format evolves, but currently used as a general guideline. Units are implicit (e.g., mm, inches) and must be consistent throughout the file. */

minTraceWidth: number;

/** An array of obstacles on the board, such as component pads, mounting holes, or keep-out areas. */

obstacles: Obstacle[];

/** An array defining the electrical connections (nets) that need to be routed. */

connections: Array;

/** The bounding box defining the extents of the routing area. */

bounds: { minX: number; maxX: number; minY: number; maxY: number };

/** [Optional] The routing solution provided by an autorouter. This array contains the actual paths of the traces. It is typically absent in the input file given to a router and present in the output file. */

traces?: SimplifiedPcbTrace[];

}

```

## Top-Level Properties

### `layerCount`

* **Type:** `number`

* **Description:** An integer specifying the total number of conductive layers available for routing on the PCB. Layers are typically identified by string names (e.g., `"top"`, `"inner1"`, `"bottom"`) within other parts of the format (like `obstacles` and `connections`). While `layerCount` provides the total number, the specific layer names used must be consistent throughout the file.

### `minTraceWidth`

* **Type:** `number`

* **Description:** Specifies the default or minimum trace width to be used by the autorouter. This acts as a global constraint. Future versions or specific router implementations might allow per-net or per-segment width rules, but this provides a baseline.

* **Units:** Units (e.g., millimeters, inches) are not explicitly defined by the format. It is crucial that the same unit system is used consistently for all dimensional values (`minTraceWidth`, `obstacles`, `bounds`, coordinates) within a single SRJ file. Millimeters (mm) are commonly used.

### `obstacles`

* **Type:** `Array`

* **Description:** An array containing objects that represent areas on the PCB where routing is either restricted or represents a connection point. Obstacles can be physical component pads, mounting holes, board edges defined as keep-outs, or explicit keep-out zones.

```typescript

export type Obstacle = {

/** The shape of the obstacle. Currently, only "rect" is standard. Oval shapes might be included in future revisions. */

type: "rect"; // NOTE: most datasets do not contain ovals

/** An array of layer names (strings) on which this obstacle exists. An obstacle can span multiple layers (e.g., a plated through-hole pad). */

layers: string[];

/** The center coordinates of the obstacle. */

center: { x: number; y: number };

/** The width of the rectangular obstacle. */

width: number;

/** The height of the rectangular obstacle. */

height: number;

/** An array of connection names (strings) that this obstacle is part of. If this obstacle is a pad for a net (e.g., "GND", "VCC"), the net name(s) will be listed here. If the array is empty, the obstacle is typically a keep-out area or an unconnected feature. */

connectedTo: string[];

};

```

* **`type`**: Defines the geometry. Currently `"rect"` is the standard.

* **`layers`**: Specifies which layer(s) the obstacle occupies. Important for multi-layer routing.

* **`center`, `width`, `height`**: Define the geometry and position of the rectangle. Units must be consistent with `minTraceWidth` and `bounds`.

* **`connectedTo`**: This critical field links obstacles (like pads) to the electrical nets defined in the `connections` array. If an obstacle represents a pin for the "VCC" net, `connectedTo` would contain `["VCC"]`.

### `connections`

* **Type:** `Array`

* **Description:** Defines the sets of points that need to be electrically connected. Each object in the array represents a single net (e.g., power, ground, signal).

```typescript

export interface SimpleRouteConnection {

/** The unique name of the connection or net (e.g., "GND", "VCC", "DATA0"). This name is referenced by Obstacle.connectedTo. */

name: string;

/** An array of points that must be connected together to form this net. Each point typically corresponds to the center of an obstacle (pad) belonging to this net. */

pointsToConnect: Array<{

/** The x-coordinate of the connection point. */

x: number;

/** The y-coordinate of the connection point. */

y: number;

/** The layer name (string) on which this connection point resides. */

layer: string;

}>;

}

```

* **`name`**: A unique string identifier for the net. This is used to link `Obstacle` objects (pads) to their respective nets.

* **`pointsToConnect`**: An array listing the specific locations (`x`, `y`, `layer`) that the router must connect. These points usually align with the `center` coordinates and `layers` of the corresponding `Obstacle` objects linked via the `name`.

### `bounds`

* **Type:** `object`

* **Description:** Defines the rectangular boundary of the area where routing is permitted. Traces should generally not extend beyond these limits.

* **Structure:**

* `minX`: The minimum x-coordinate of the routing area.

* `maxX`: The maximum x-coordinate of the routing area.

* `minY`: The minimum y-coordinate of the routing area.

* `maxY`: The maximum y-coordinate of the routing area.

* **Units:** Must be consistent with other dimensional values in the file.

### `traces` (Optional)

* **Type:** `Array`

* **Description:** This array represents the output of an autorouter – the actual geometric paths (traces and vias) that implement the required connections. It is typically **not present** in the input SRJ file given to the router.

* **Presence:** Included in the SRJ file *after* routing has been successfully completed.

```typescript

export type SimplifiedPcbTrace = {

/** Identifier indicating the object type. Always "pcb_trace". */

type: "pcb_trace";

/** A unique identifier for this specific trace path. */

pcb_trace_id: string;

/** [Optional] The name of the connection/net this trace belongs to. Links the solved route back to the SimpleRouteConnection definition. */

connection_name?: string;

/** An array defining the geometry of the trace path, composed of wire segments and vias. */

route: Array<

| {

/** Indicates a straight wire segment on a single layer. */

route_type: "wire";

/** The x-coordinate of the *end* point of the wire segment. */

x: number;

/** The y-coordinate of the *end* point of the wire segment. */

y: number;

/** The width of this wire segment. */

width: number;

/** The layer name (string) this wire segment is on. */

layer: string;

}

| {

/** Indicates a via connecting two layers. */

route_type: "via";

/** The x-coordinate of the via's center. */

x: number;

/** The y-coordinate of the via's center. */

y: number;

/** The layer name (string) the via transitions *to*. */

to_layer: string;

/** The layer name (string) the via transitions *from*. */

from_layer: string;

}

>;

};

```

* **`type`**: Always `"pcb_trace"`.

* **`pcb_trace_id`**: Unique ID for the trace.

* **`connection_name`**: Links trace to the net name from `connections`.

* **`route`**: An ordered array describing the path:

* **`wire`**: Represents a straight segment of copper trace. The segment runs from the end point of the previous element in the `route` array (or an initial connection point) to the specified `(x, y)` coordinate on the given `layer` with the specified `width`.

* **`via`**: Represents a vertical connection between layers at `(x, y)`, transitioning from `from_layer` to `to_layer`. Note that physical via characteristics (drill size, annular ring) are not detailed in this simplified format.

## Example

```json

{

"layerCount": 2,

"minTraceWidth": 0.15,

"obstacles": [

{

"type": "rect",

"layers": ["top"],

"center": { "x": 10, "y": 10 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["VCC"]

},

{

"type": "rect",

"layers": ["top"],

"center": { "x": 30, "y": 10 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["VCC"]

},

{

"type": "rect",

"layers": ["bottom"],

"center": { "x": 20, "y": 25 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["GND"]

},

{

"type": "rect",

"layers": ["bottom"],

"center": { "x": 40, "y": 25 },

"width": 1.2,

"height": 1.2,

"connectedTo": ["GND"]

},

{

"type": "rect",

"layers": ["top", "bottom"], // Keepout on both layers

"center": { "x": 25, "y": 15 },

"width": 5,

"height": 3,

"connectedTo": [] // Empty means it's a keepout

}

],

"connections": [

{

"name": "VCC",

"pointsToConnect": [

{ "x": 10, "y": 10, "layer": "top" },

{ "x": 30, "y": 10, "layer": "top" }

]

},

{

"name": "GND",

"pointsToConnect": [

{ "x": 20, "y": 25, "layer": "bottom" },

{ "x": 40, "y": 25, "layer": "bottom" }

]

}

],

"bounds": {

"minX": 0,

"maxX": 50,

"minY": 0,

"maxY": 40

},

// --- TRACES SECTION (added by router) ---

"traces": [

{

"type": "pcb_trace",

"pcb_trace_id": "trace_vcc_1",

"connection_name": "VCC",

"route": [

{ "route_type": "wire", "x": 10, "y": 10, "width": 0.15, "layer": "top" }, // Start implicitly at first point

{ "route_type": "wire", "x": 20, "y": 5, "width": 0.15, "layer": "top" },

{ "route_type": "wire", "x": 30, "y": 10, "width": 0.15, "layer": "top" } // End at second point

]

},

{

"type": "pcb_trace",

"pcb_trace_id": "trace_gnd_1",

"connection_name": "GND",

"route": [

{ "route_type": "wire", "x": 20, "y": 25, "width": 0.15, "layer": "bottom" }, // Start implicitly at first point

// Example with a via

{ "route_type": "wire", "x": 30, "y": 25, "width": 0.15, "layer": "bottom" },

{ "route_type": "via", "x": 30, "y": 25, "from_layer": "bottom", "to_layer": "top" },

{ "route_type": "wire", "x": 30, "y": 20, "width": 0.15, "layer": "top" }, // Segment on top layer

{ "route_type": "via", "x": 30, "y": 20, "from_layer": "top", "to_layer": "bottom" },

{ "route_type": "wire", "x": 40, "y": 25, "width": 0.15, "layer": "bottom" } // End at second point

]

}

]

}

```

## Units and Coordinate System

The Simple Route JSON format does **not** enforce specific units (e.g., mm, mil, inches) or a coordinate system origin (e.g., top-left, bottom-left).

* **Consistency is Key:** All dimensional values (`minTraceWidth`, obstacle `width`/`height`, `bounds`, all `x`/`y` coordinates in `obstacles`, `connections`, and `traces`) within a single SRJ file **must** use the same units.

* **Common Practice:** Millimeters (mm) are frequently used.

* **Origin:** The coordinate system origin is typically assumed to be top-left or bottom-left, with X increasing to the right and Y increasing downwards (top-left) or upwards (bottom-left). Consistency within the file and between the SRJ generator and consumer (the autorouter) is essential.

## Relationship to Other Formats

* **Circuit JSON:** Simple Route JSON is a simplified derivative of Circuit JSON. Tools can convert Circuit JSON to SRJ by extracting layer stackup information, component pad locations and net assignments, board outlines, and any defined keep-out areas. Information not relevant to routing (e.g., schematic IDs, component values, 3D models) is omitted.

* **Specctra DSN:** SRJ serves a similar purpose to DSN files – describing a routing problem. However, SRJ uses a modern JSON structure, which is often easier to parse and generate in web-based and JavaScript/TypeScript environments compared to the text-based, keyword-driven DSN format. The `dsn-converter` tool ([link](https://github.com/tscircuit/dsn-converter)) can facilitate conversion between DSN and SRJ or similar formats.

## Usage

The primary use case for Simple Route JSON is as the input and output format for `tscircuit` autorouting tools.

1. **Input:** A PCB design tool or conversion script generates an SRJ file describing the board, obstacles, and connections. This file is fed into an autorouter.

2. **Output:** The autorouter processes the input SRJ, computes the trace paths, and outputs a new SRJ file that includes the original data plus the `traces` array detailing the solution.

3. **Post-processing:** The output SRJ (with traces) can then be converted back into a format compatible with PCB design software (like Circuit JSON, KiCad, Eagle, etc.) to integrate the routing solution into the full PCB design.

```

---

title: tscircuit Units

description: Understanding default units in tscircuit for length, electrical properties, and other measurements.

---

In tscircuit you can specify a unit explicitly with a string e.g. "0.1mm", but

you can also also specify numbers without units and the unit will be inferred

from [platform](../guides/running-tscircuit/platform-configuration.md), [board configuration](../elements/board.mdx), [subcircuit configuration](../elements/subcircuit.mdx)

or the defaults below

## Default Units

By default, tscircuit uses the following base units:

| Measurement Type | Base Unit | Description |

| ---------------- | --------- | ------------ |

| Length | mm | Millimeters |

| Time | ms | Milliseconds |

| Mass | g | Grams |

| Angle | deg | Degrees |

| Frequency | Hz | Hertz |

| Volume | ml | Milliliters |

| Voltage | V | Volts |

| Current | A | Amperes |

| Resistance | Ω | Ohms |

| Capacitance | F | Farads |

| Inductance | H | Henries |

Base units are chosen based on the industry convention.

---

title: Designing Electronics from Scratch

sidebar_position: 2

description: A comprehensive guide to electronics design workflow - from requirements analysis through system diagramming, schematic capture, PCB layout, to final manufacturing

---

## Overview

Typically electronics engineers go through the following steps when designing

a new electronic device.

1. Requirements Analysis

2. System Diagramming

3. Schematic Capture

4. PCB Layout

5. Ordering

## Requirements Analysis

This stage is all about making sure you have a clear idea of what the device

should do. Your development and cost preferences are a huge factor here.

1. What should the device do?

2. How much power is needed?

3. How much processing power do I need?

4. Do I want to run linux, MicroPython, or low-level C code? Do I even need

to run code?

5. How much does cost matter?

6. Should I use only parts available from turn-key manufacturers like JLCPCB?

## System Diagramming

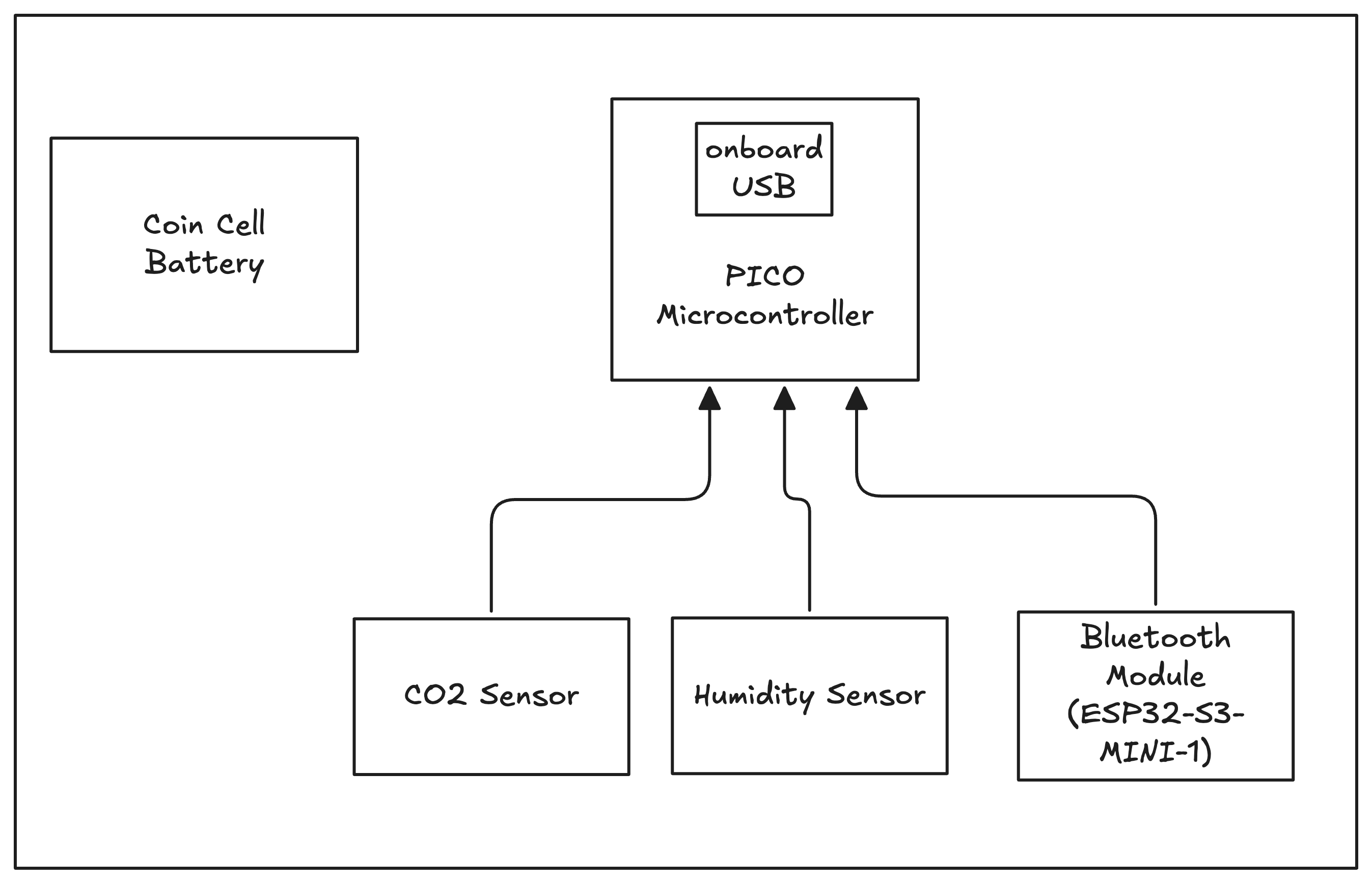

In this phase we create a diagram overview of the system and how things connect

together abstractly

1. What components should I use?

2. How do things connect together at a high level?

The system diagram can instantly communicate how your design works to others.

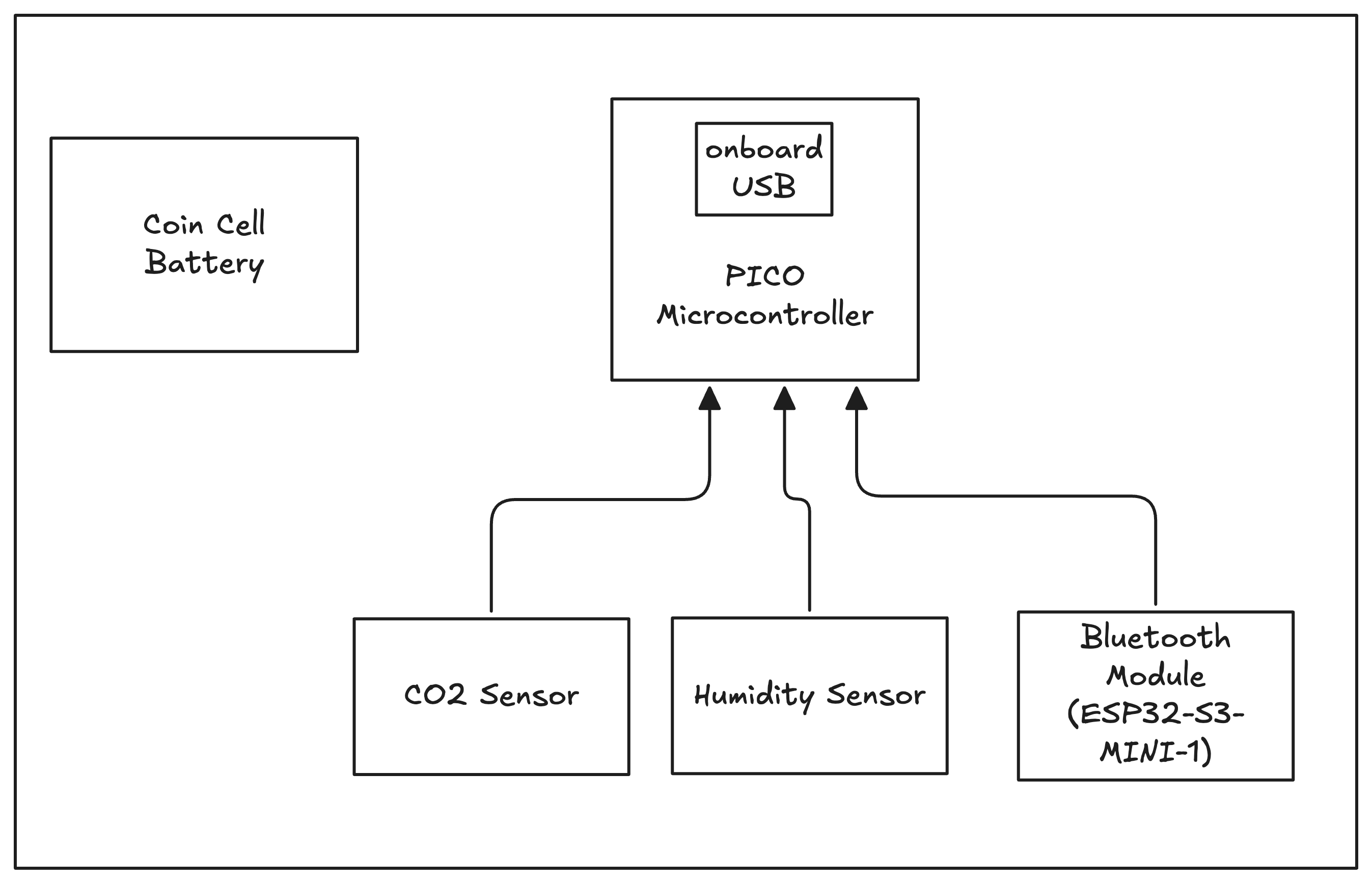

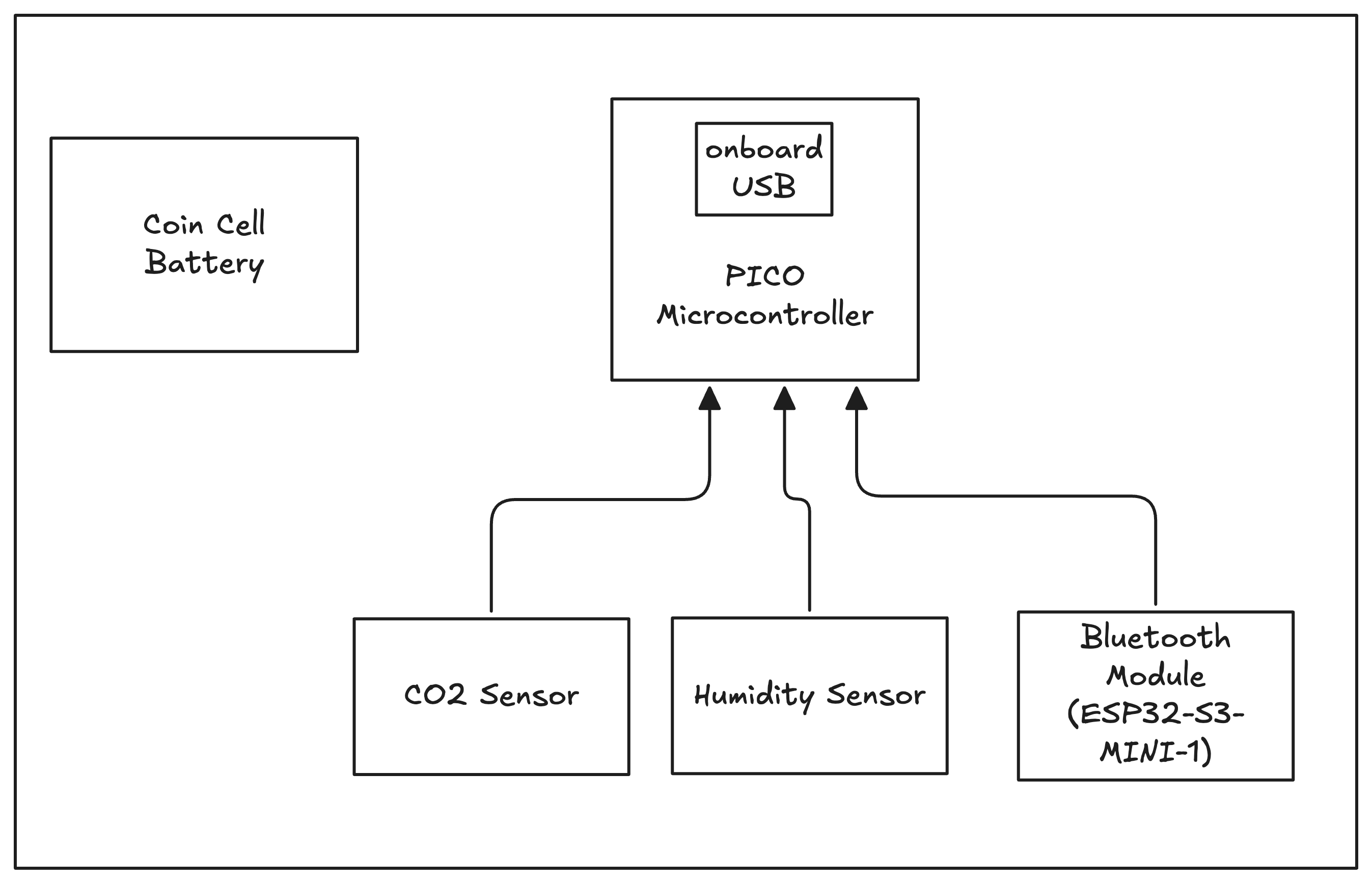

### System Diagram Example 1: Bluetooth Humidity and CO2 Sensor

Here's an example of a system diagram for a simple IoT device that takes

humidity and CO2 measurements and can communicate them via bluetooth.

System Diagram Example 1

## Schematic Capture

In this phase we create a schematic diagram of the system and how things connect

together.

1. Using reference designs, datasheets or pre-made modules, create all the

elements of the circuit in tscircuit

2. Run design checks to make sure the circuit is hooked up correctly

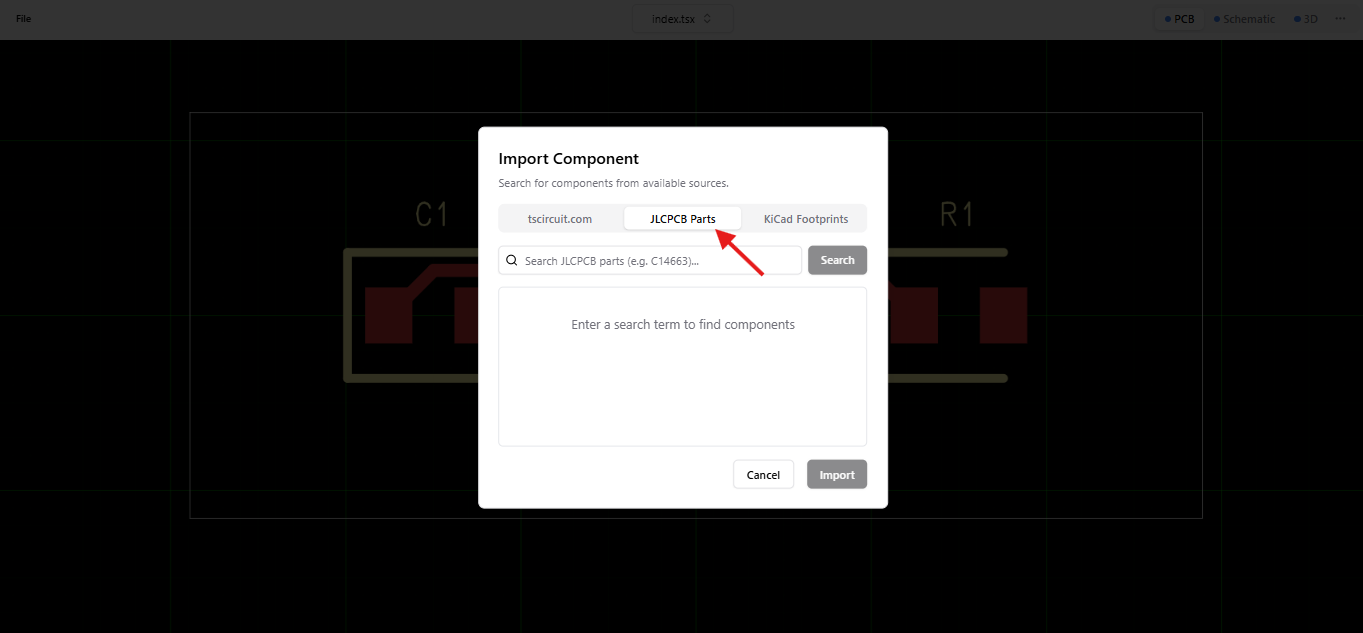

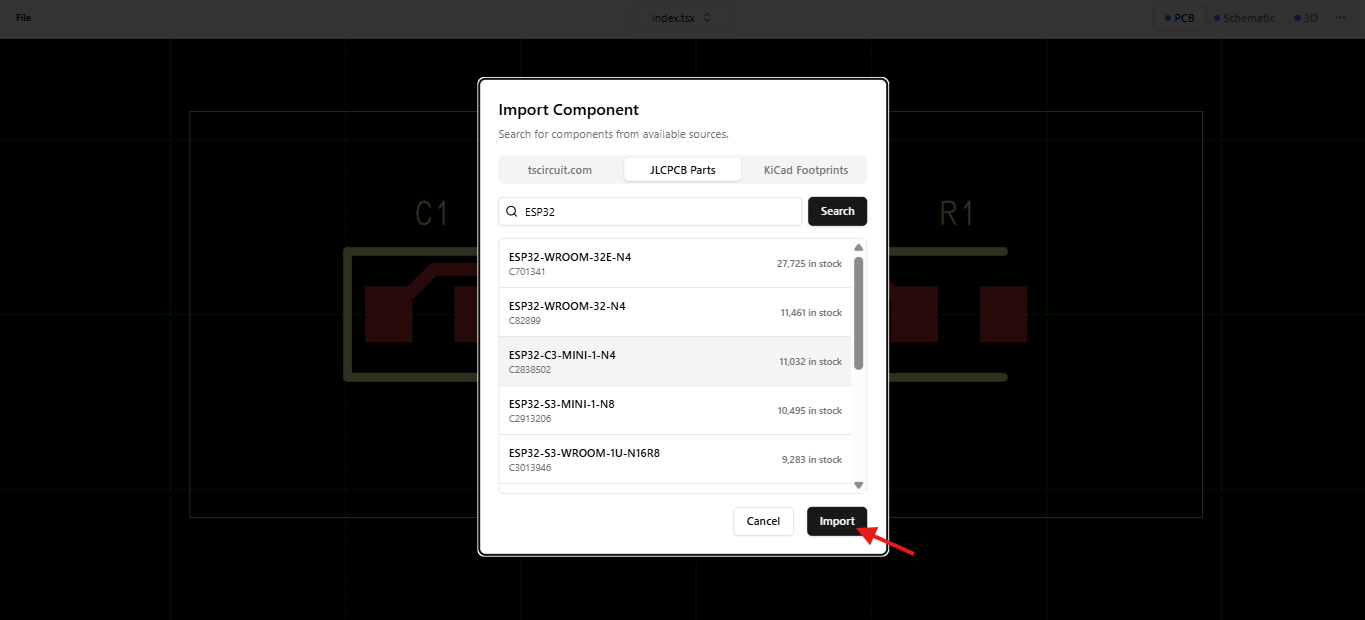

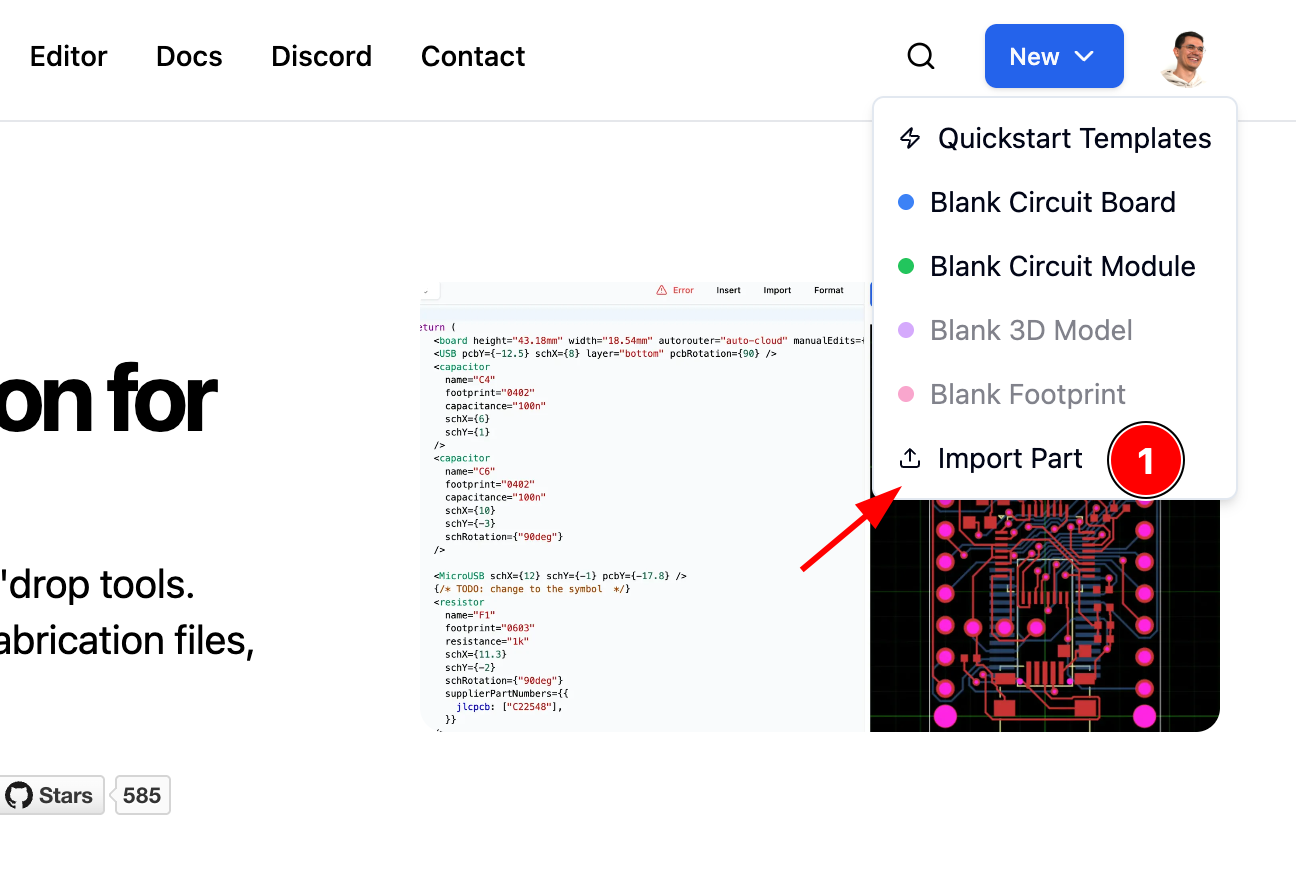

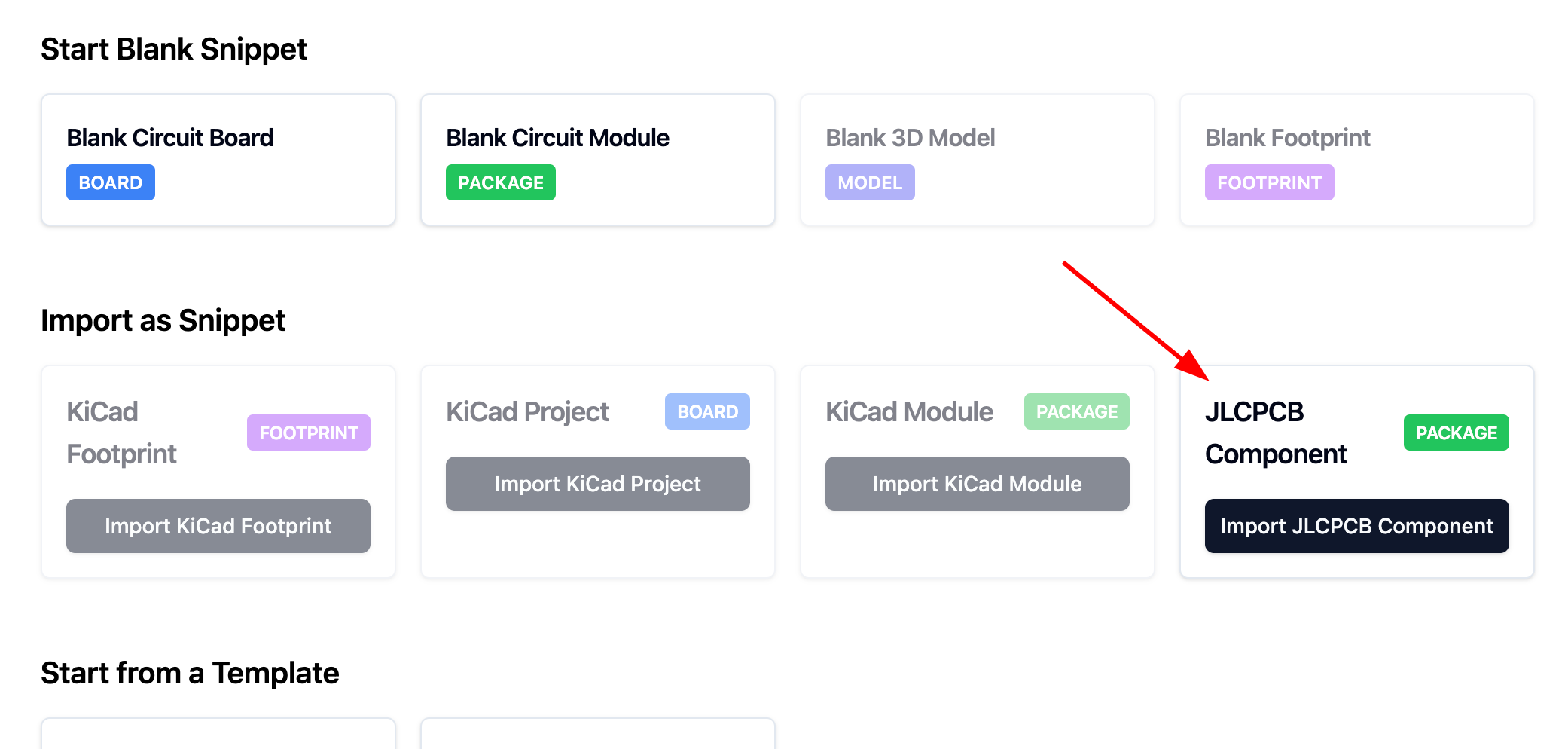

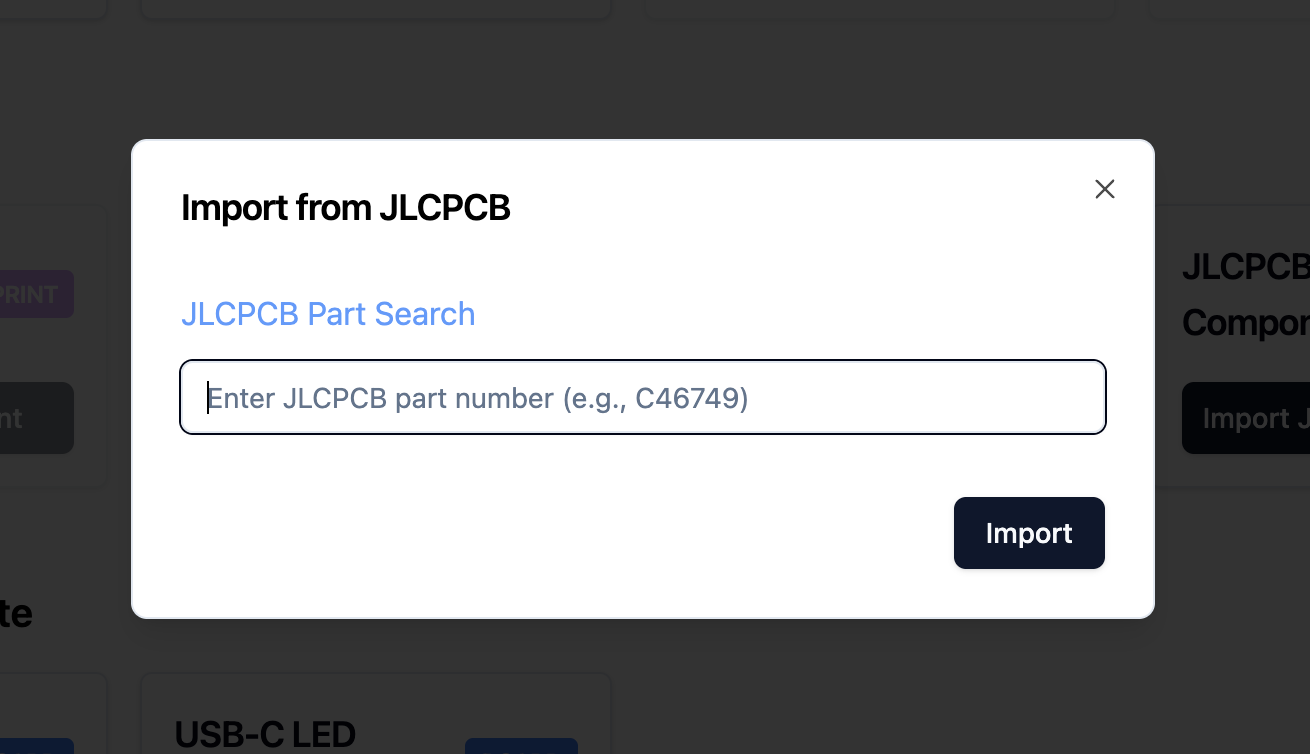

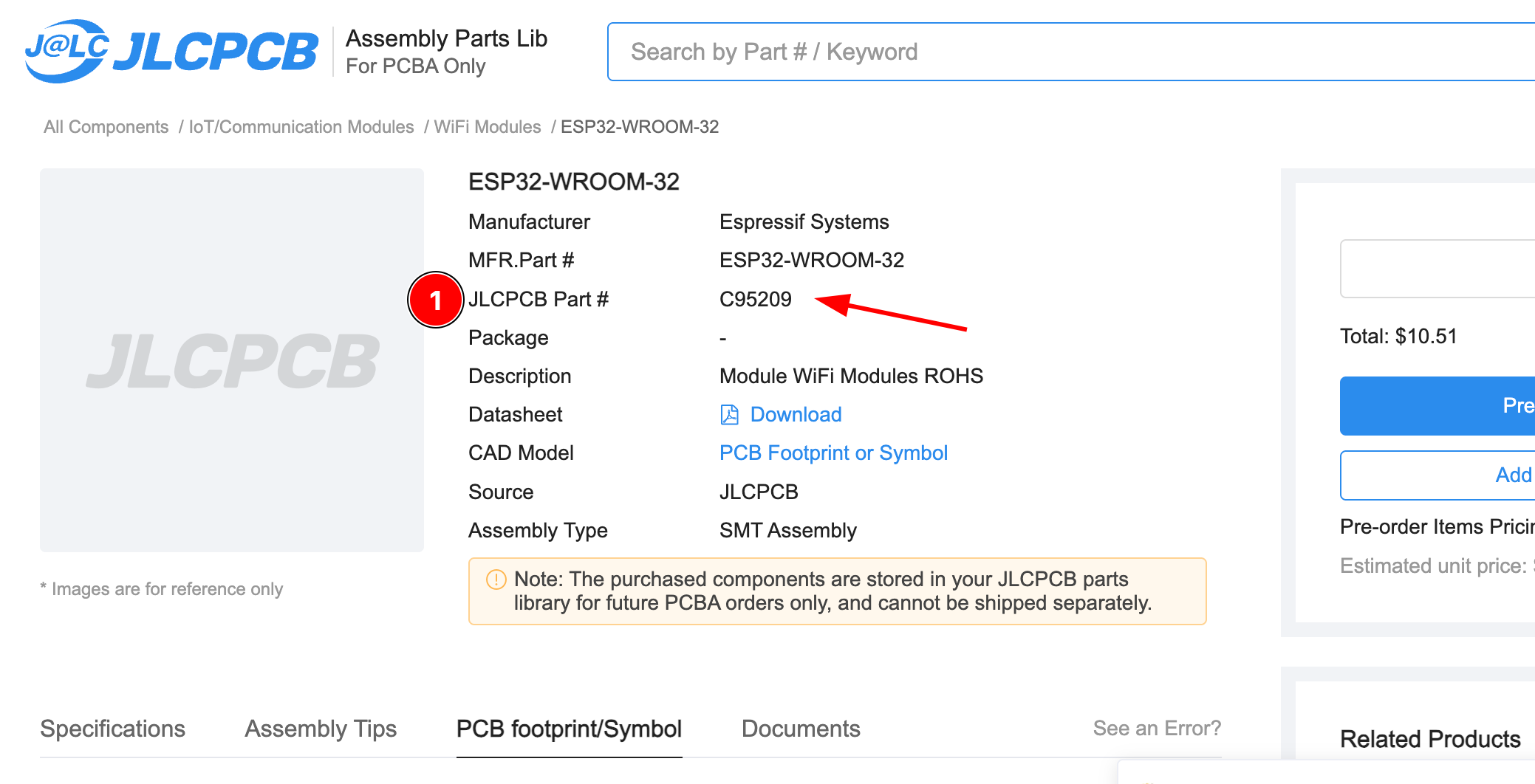

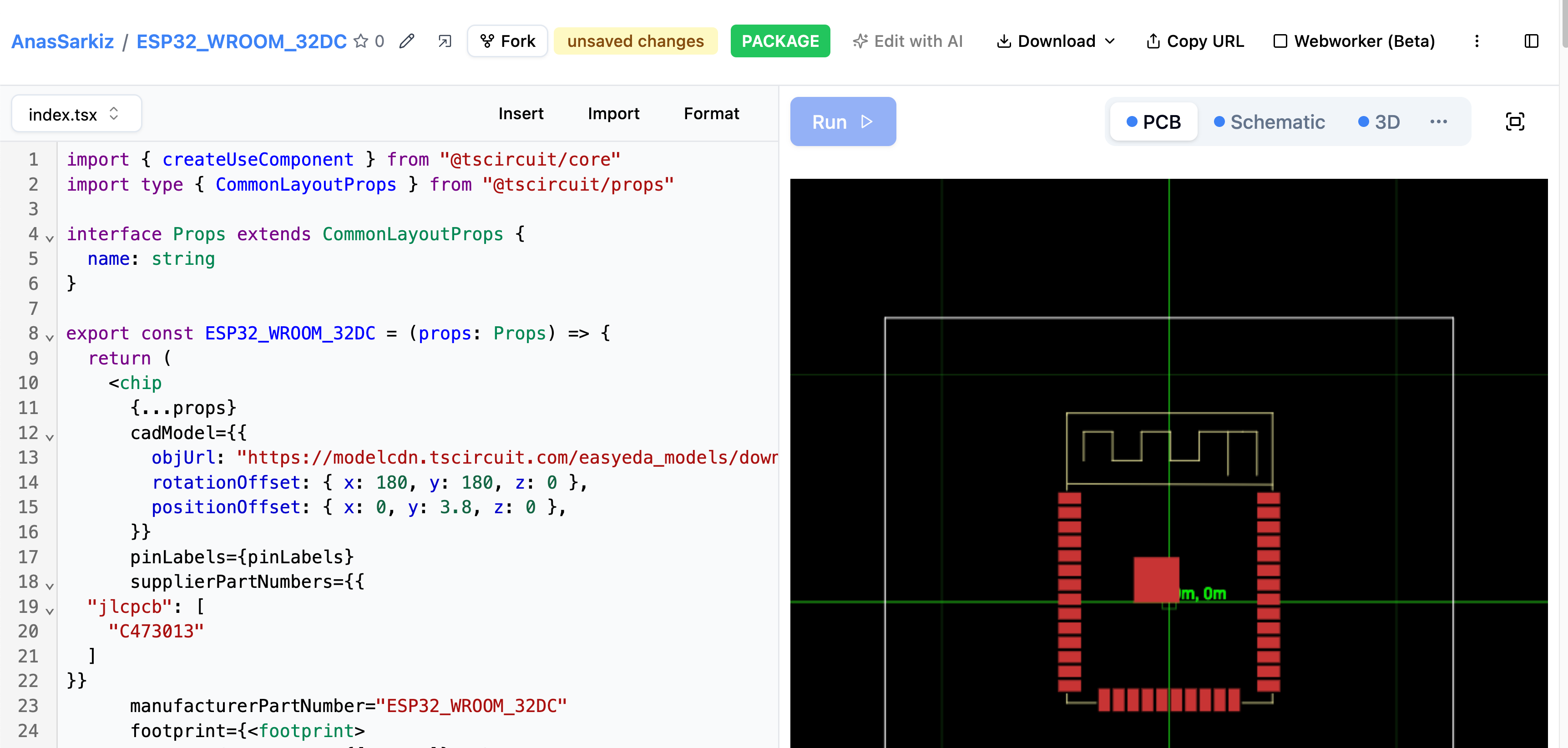

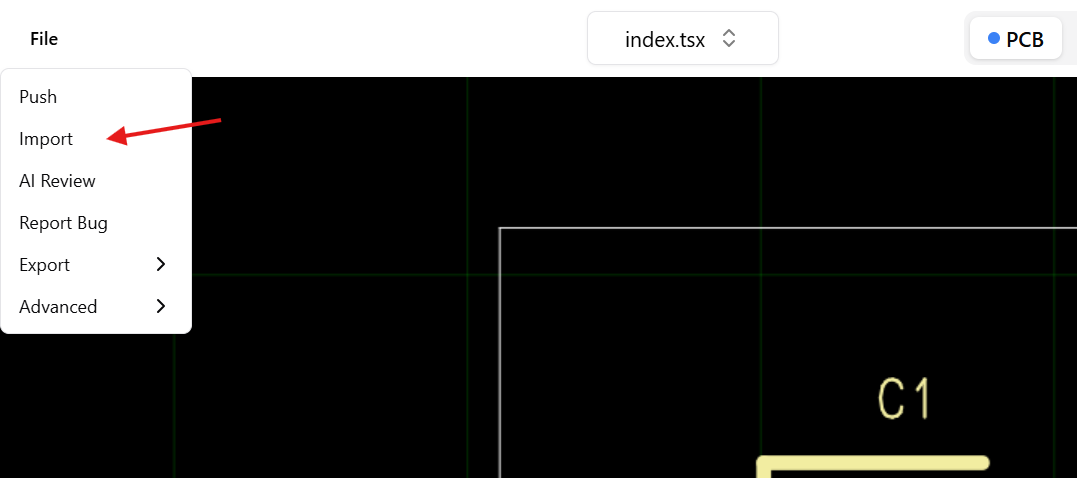

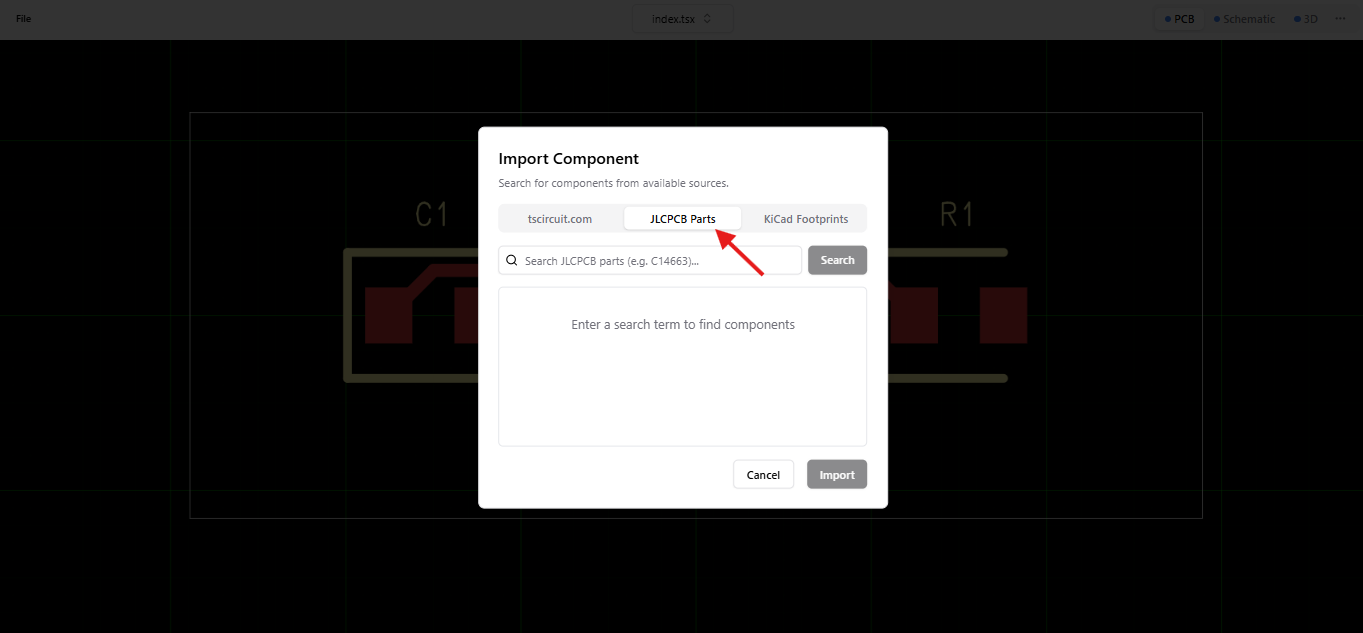

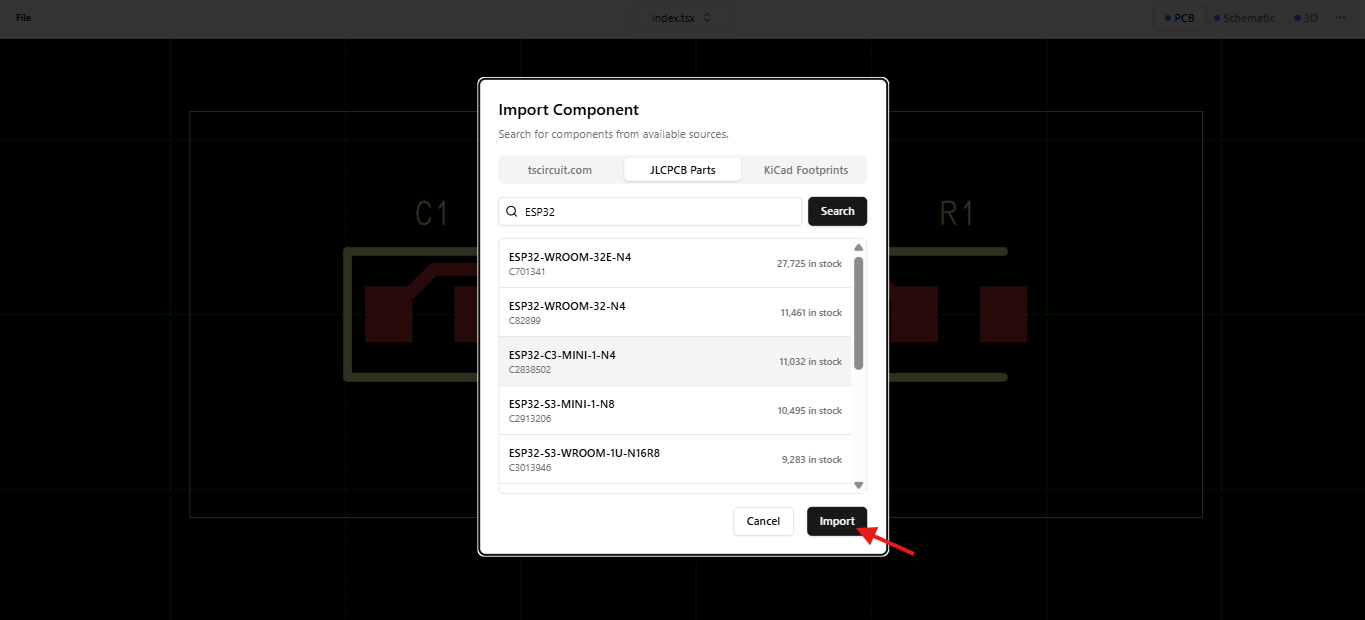

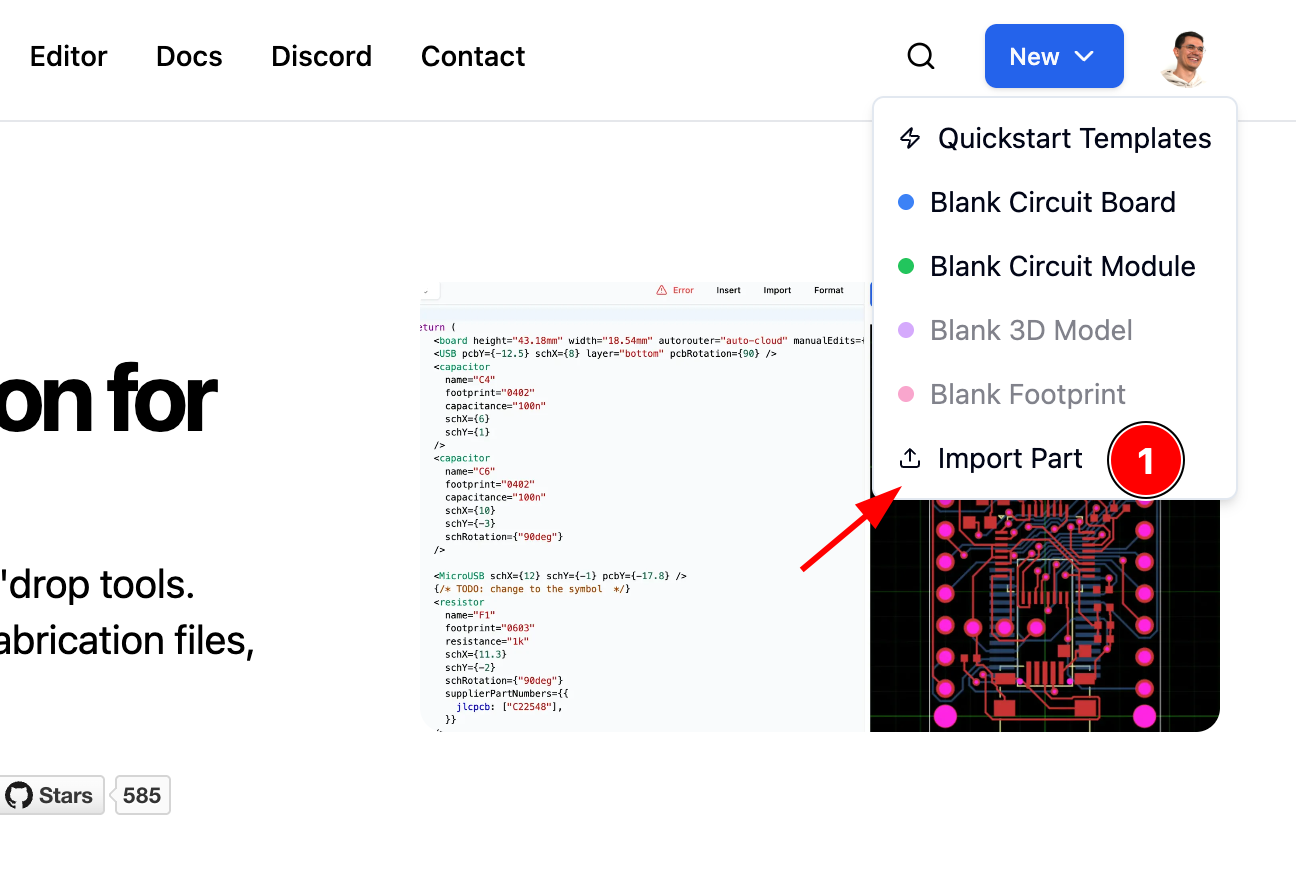

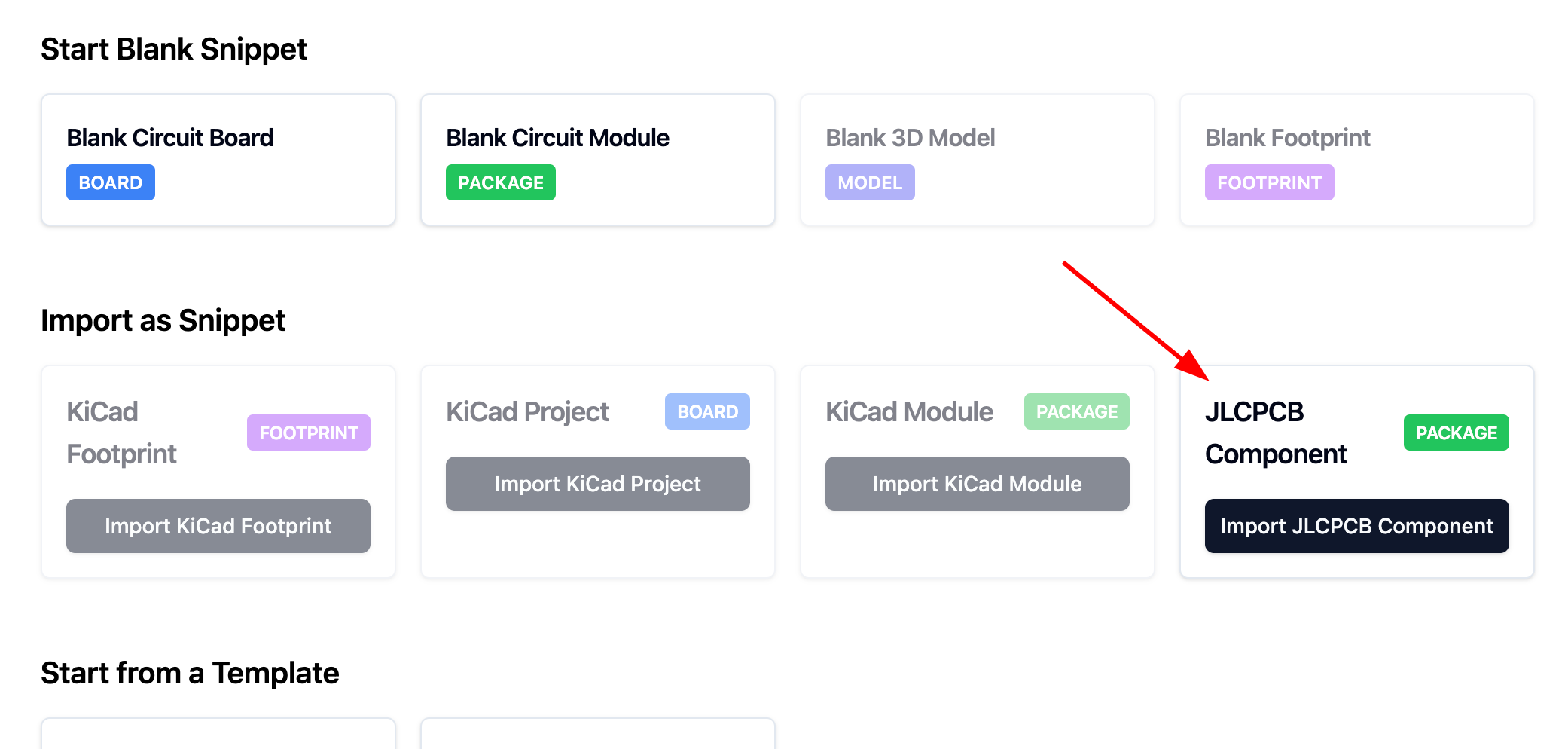

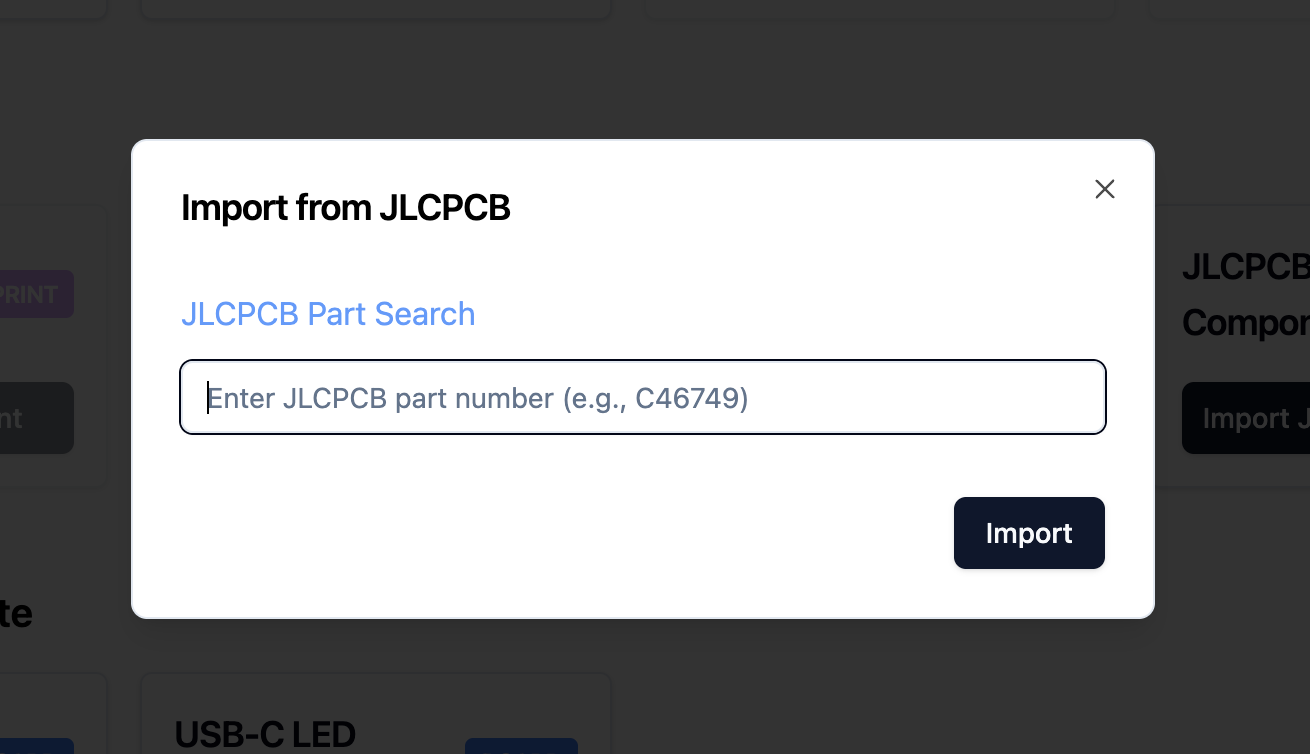

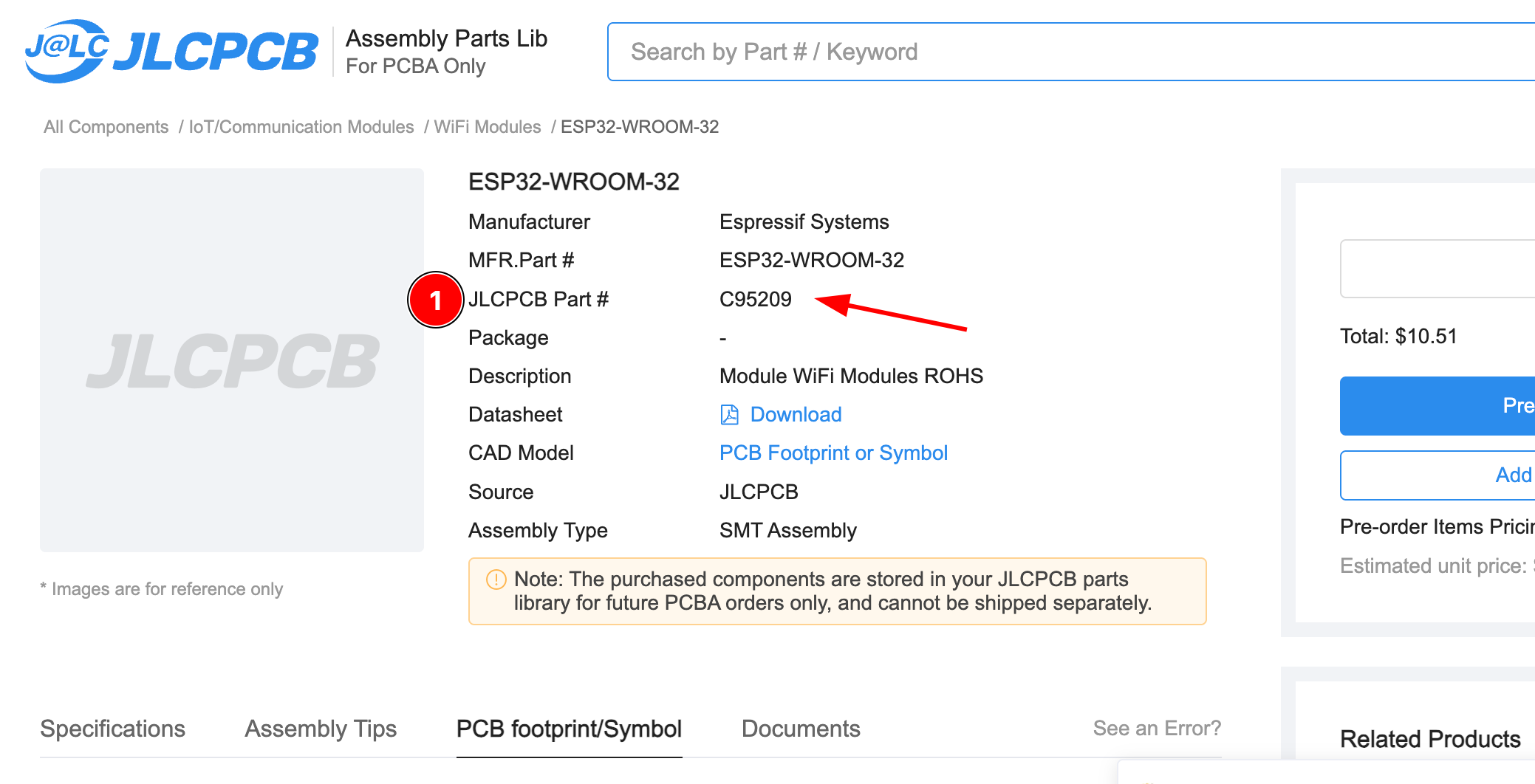

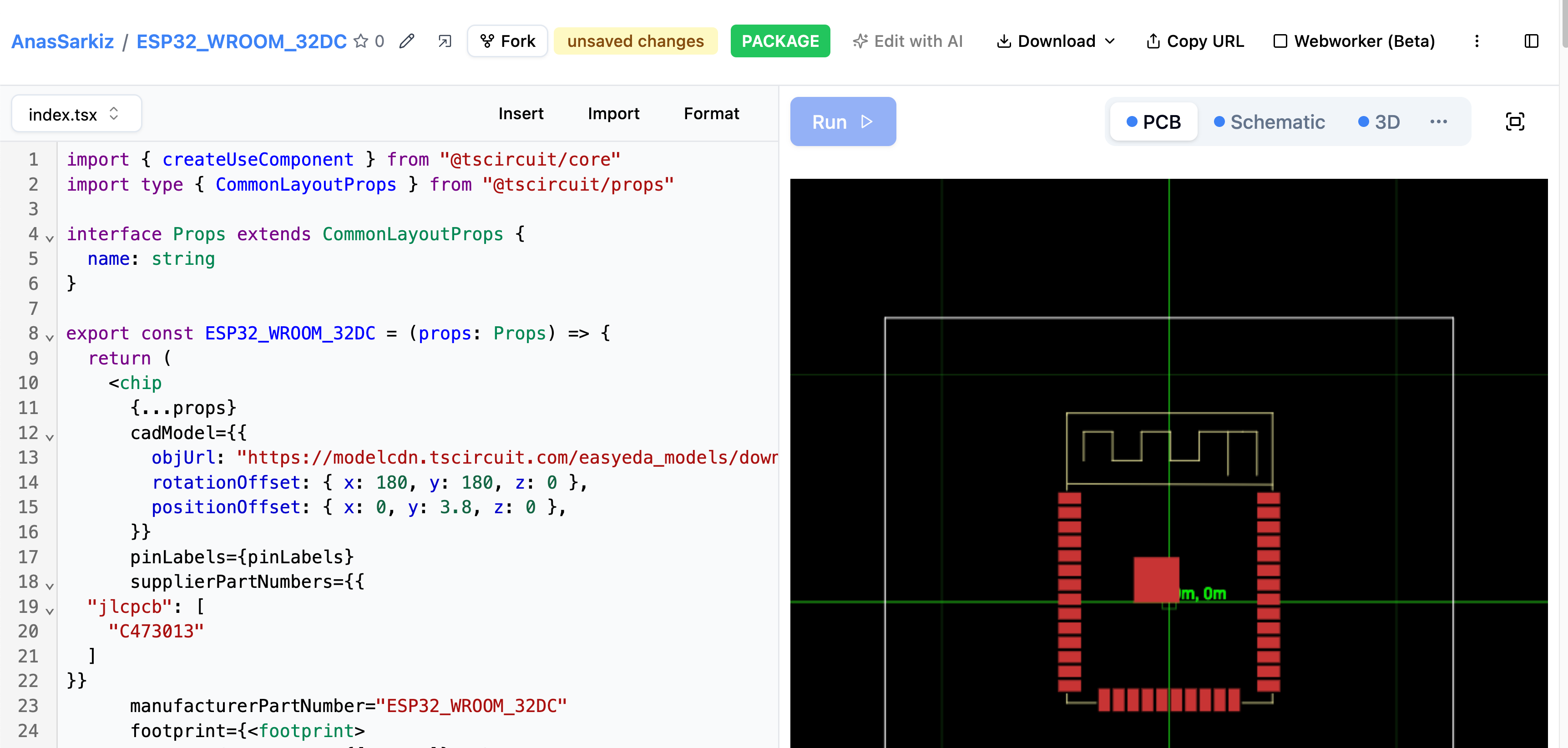

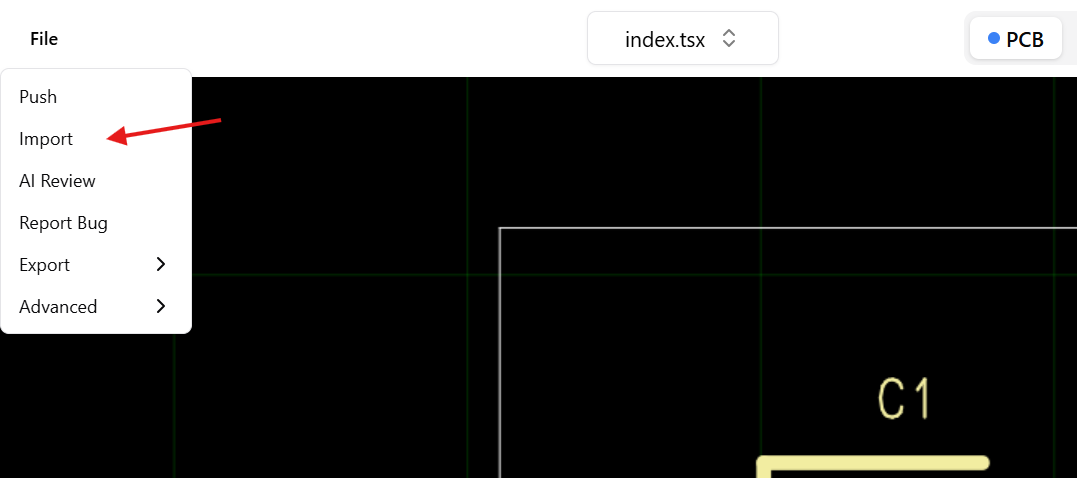

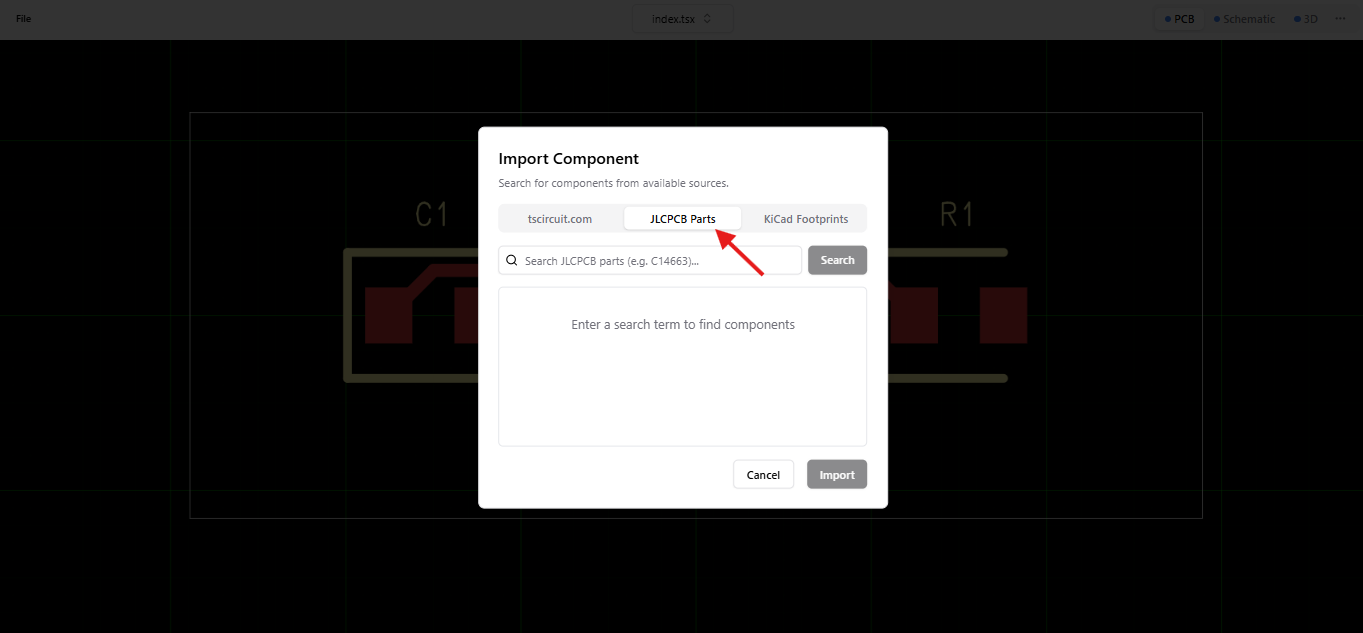

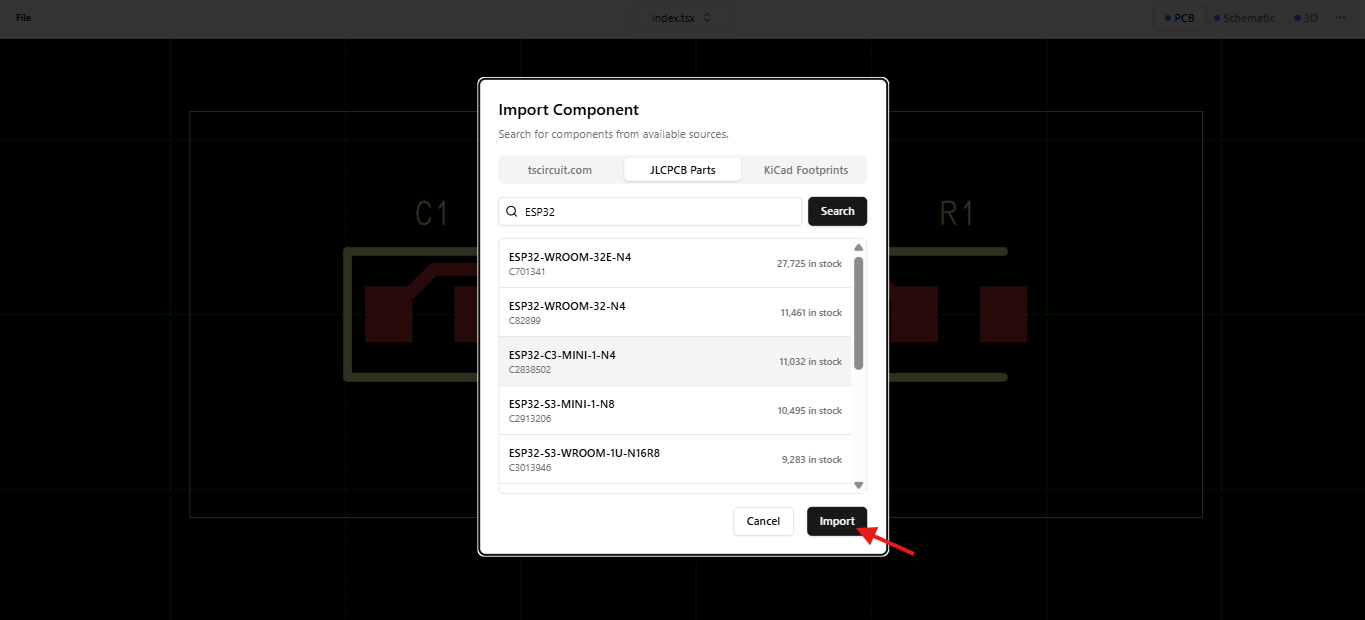

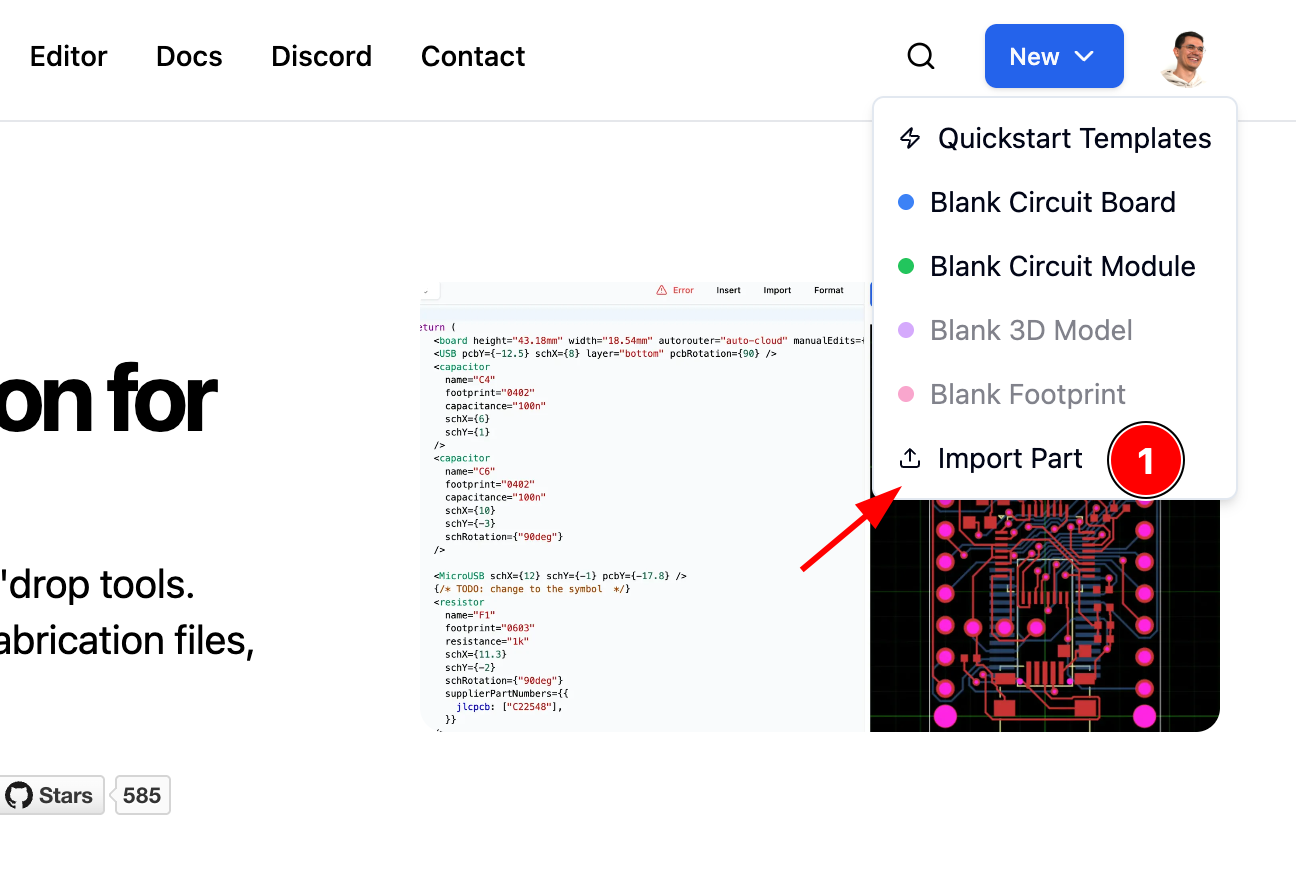

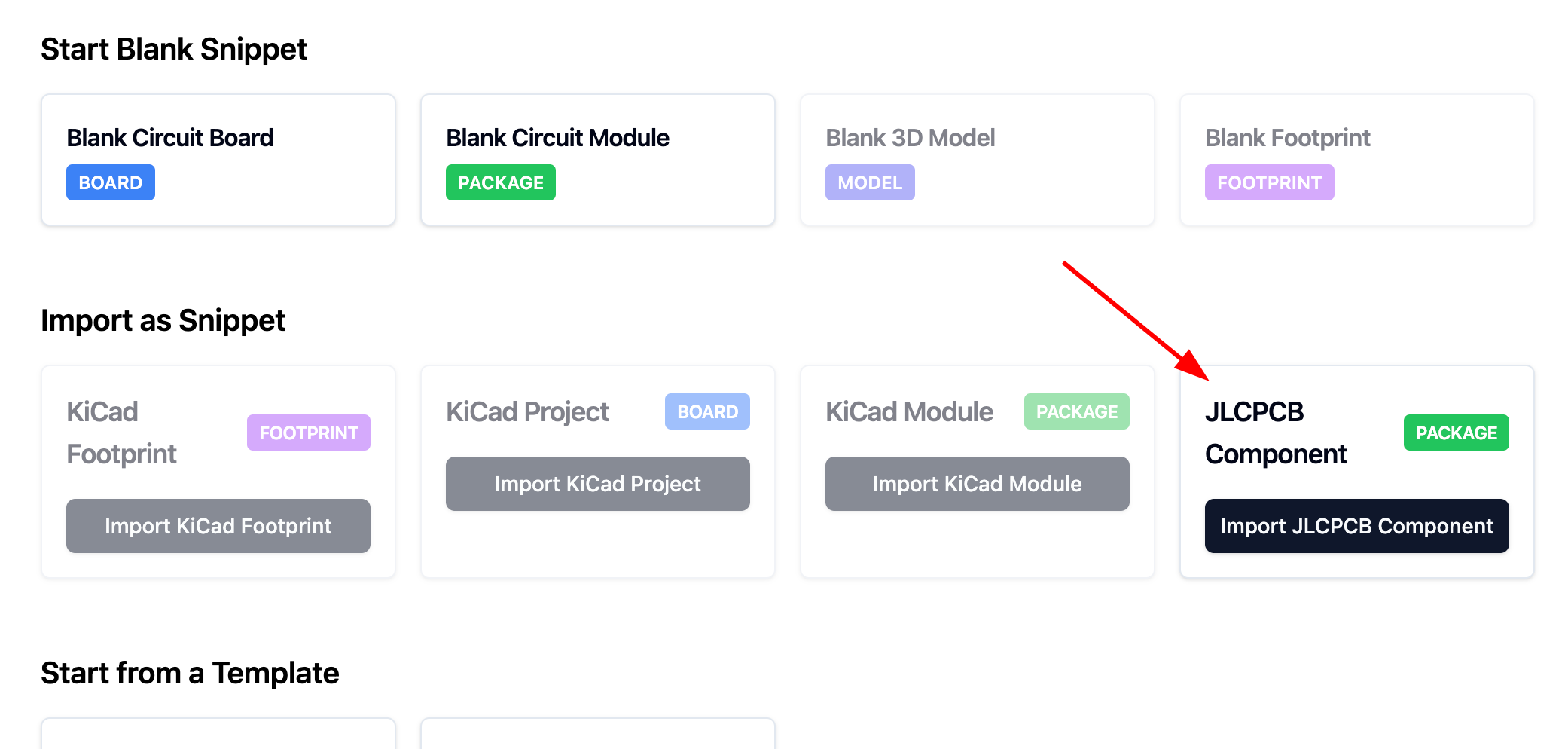

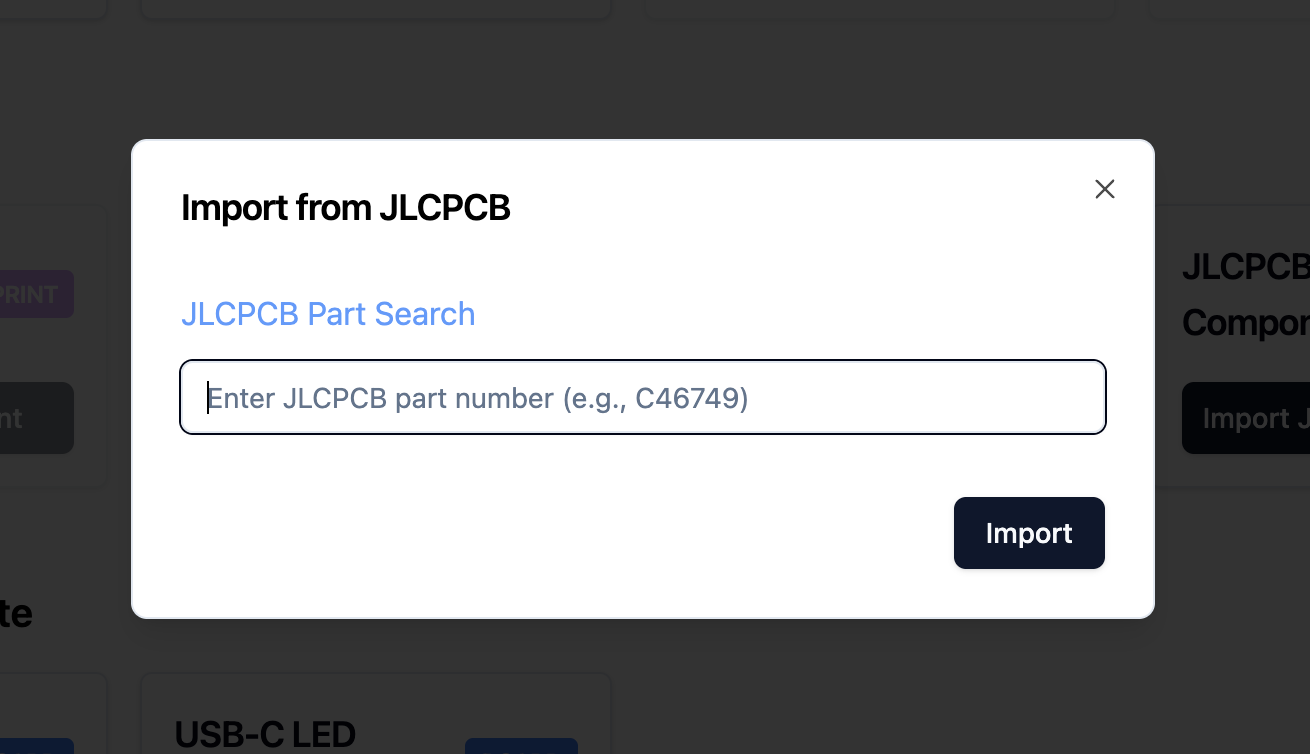

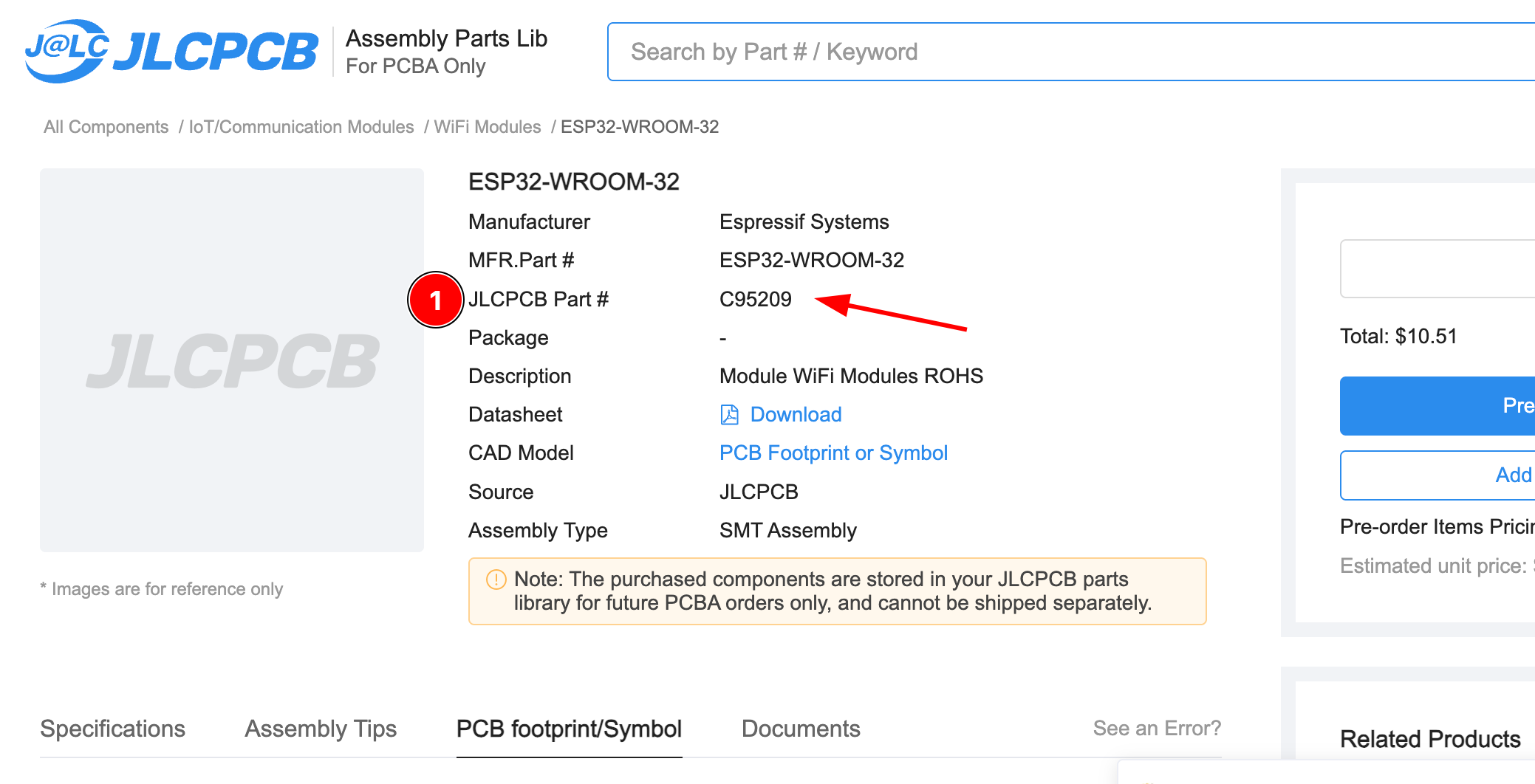

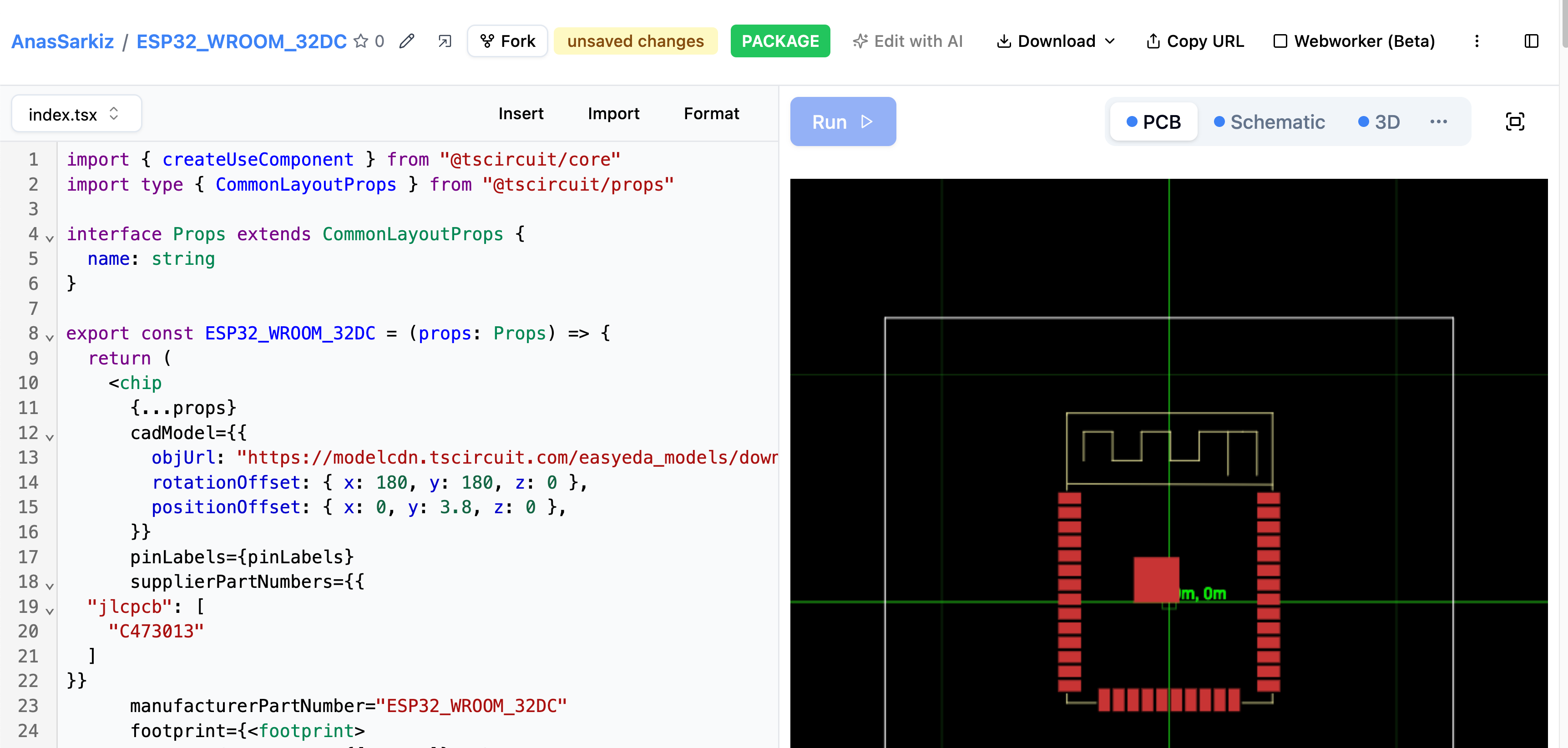

In this phase you should create chip modules or [import third party chips](../guides/importing-modules-and-chips/importing-from-jlcpcb.mdx)

as you build up your circuit. You shouldn't be configuring chips in

the same file that connects all your chips together- give each chip it's own

module.

After the schematics look good, you can export to a readable netlist and upload

the netlist to AI tools like OpenAI O1 to get a review and make sure everything

is connected properly! This is also a good stage to get your schematic reviewed

by your team members.

## PCB Layout

In this phase we create a layout of the circuit on a PCB.

tscircuit automatically autoroutes the circuit for you, but you may still need

to "drag'n'drop" components in the PCB viewer to the locations you want them to

be in. Use [manual editing](../guides/tscircuit-essentials/manual-edits.mdx) to drag'n'drop

components on the PCB.

## Ordering

In this phase we order the PCB from a manufacturer. Typically this is done

by downloading [Fabrication Files](../guides/understanding-fabrication-files.md)

and "dragging and dropping" them into a manufacturer's website.

Sometimes you'll want to assemble the PCB yourself (or sometimes just a single

component that your manufacturer doesn't have!). In this case, you'll need a

lab setup to facilitate soldering.

Check out our guide on [Ordering Prototypes](./ordering-prototypes.mdx) to learn more.

---

title: Ordering Prototypes

sidebar_position: 4

description: After you've designed your device, you can use fabrication files to get your device fully assembled. The two most popular services for ordering prototypes are JLCPCB and PCBWay.

---

## Overview

After [you've designed your device](./designing-electronics-from-scratch.md),

you can use [fabrication files](../guides/understanding-fabrication-files.md)

to get your device fully assembled.

The two most popular services for

ordering prototypes are [JLCPCB](https://jlcpcb.com) and [PCBWay](https://pcbway.com).

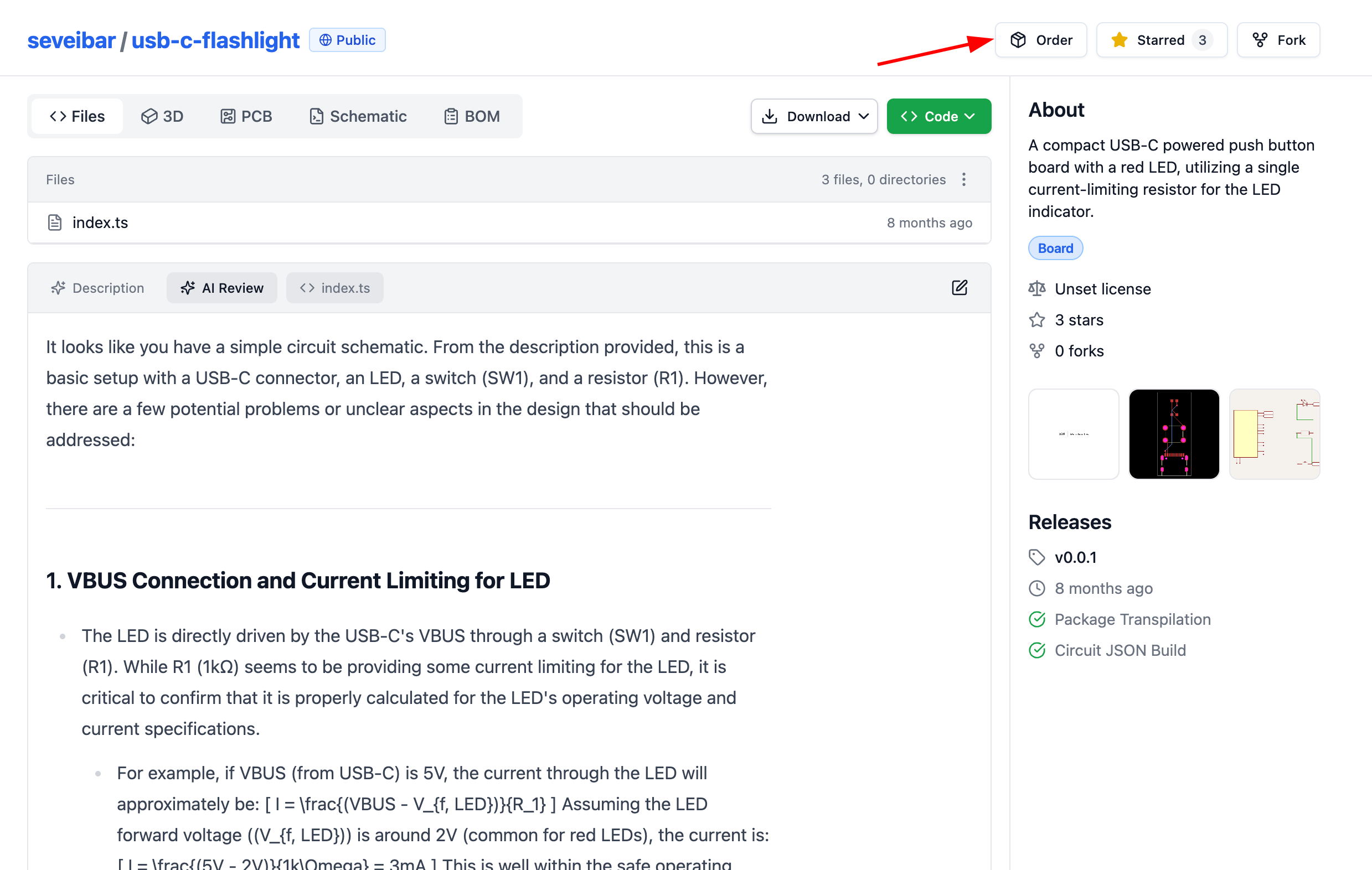

## Ordering Through tscircuit Platform

The easiest way to order your prototypes is through the tscircuit platform, which handles the entire ordering process for you.

### Ordering Steps

Here's how the ordering process works:

### 1. Get Order Quotes

Navigate to the view packages page where you'll find the order button for your circuit.

System Diagram Example 1

## Schematic Capture

In this phase we create a schematic diagram of the system and how things connect

together.

1. Using reference designs, datasheets or pre-made modules, create all the

elements of the circuit in tscircuit

2. Run design checks to make sure the circuit is hooked up correctly

In this phase you should create chip modules or [import third party chips](../guides/importing-modules-and-chips/importing-from-jlcpcb.mdx)

as you build up your circuit. You shouldn't be configuring chips in

the same file that connects all your chips together- give each chip it's own

module.

After the schematics look good, you can export to a readable netlist and upload

the netlist to AI tools like OpenAI O1 to get a review and make sure everything

is connected properly! This is also a good stage to get your schematic reviewed

by your team members.

## PCB Layout

In this phase we create a layout of the circuit on a PCB.

tscircuit automatically autoroutes the circuit for you, but you may still need

to "drag'n'drop" components in the PCB viewer to the locations you want them to

be in. Use [manual editing](../guides/tscircuit-essentials/manual-edits.mdx) to drag'n'drop

components on the PCB.

## Ordering

In this phase we order the PCB from a manufacturer. Typically this is done

by downloading [Fabrication Files](../guides/understanding-fabrication-files.md)

and "dragging and dropping" them into a manufacturer's website.

Sometimes you'll want to assemble the PCB yourself (or sometimes just a single

component that your manufacturer doesn't have!). In this case, you'll need a

lab setup to facilitate soldering.

Check out our guide on [Ordering Prototypes](./ordering-prototypes.mdx) to learn more.

---

title: Ordering Prototypes

sidebar_position: 4

description: After you've designed your device, you can use fabrication files to get your device fully assembled. The two most popular services for ordering prototypes are JLCPCB and PCBWay.

---

## Overview

After [you've designed your device](./designing-electronics-from-scratch.md),

you can use [fabrication files](../guides/understanding-fabrication-files.md)

to get your device fully assembled.

The two most popular services for

ordering prototypes are [JLCPCB](https://jlcpcb.com) and [PCBWay](https://pcbway.com).

## Ordering Through tscircuit Platform

The easiest way to order your prototypes is through the tscircuit platform, which handles the entire ordering process for you.

### Ordering Steps

Here's how the ordering process works:

### 1. Get Order Quotes

Navigate to the view packages page where you'll find the order button for your circuit.

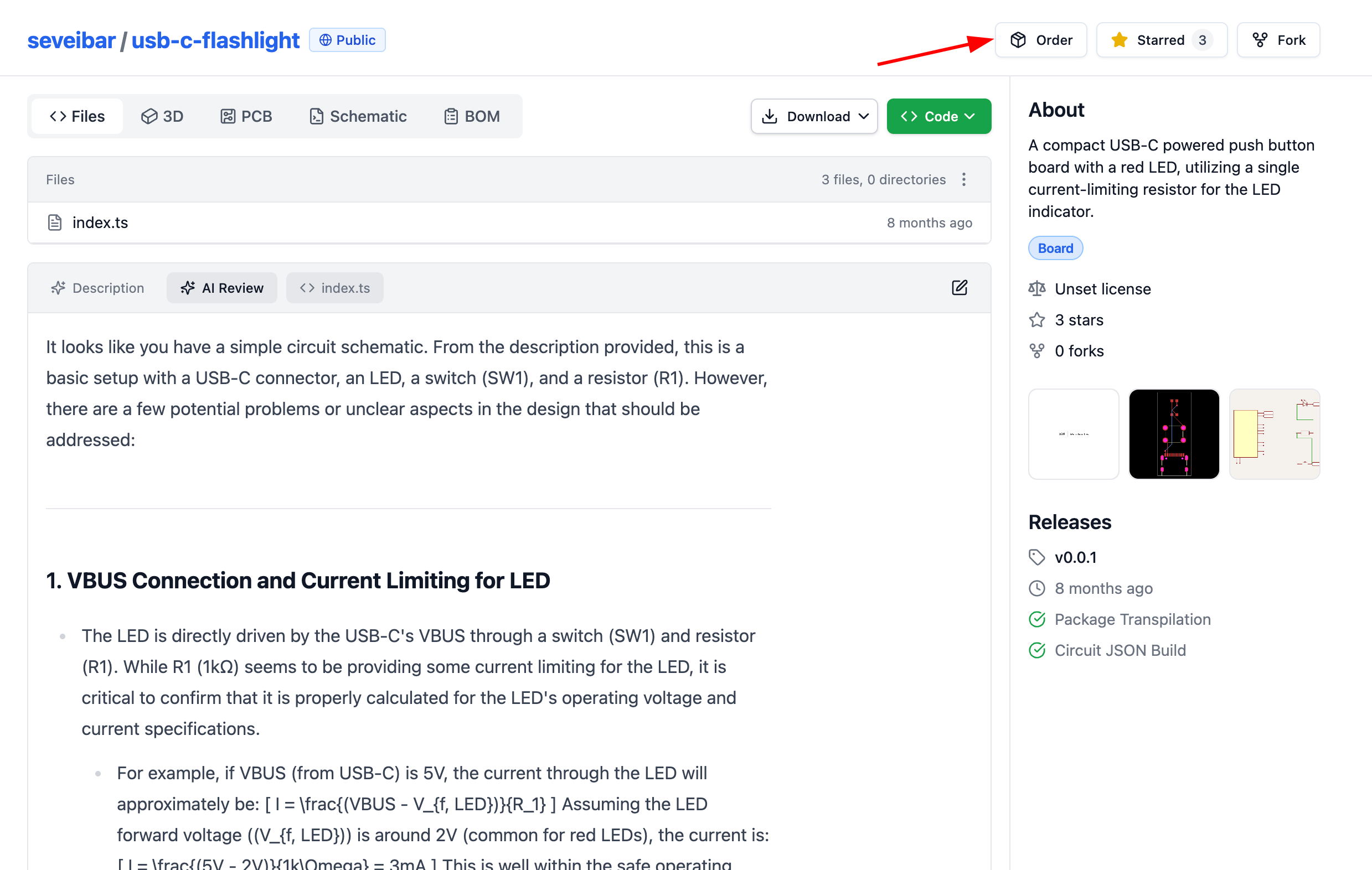

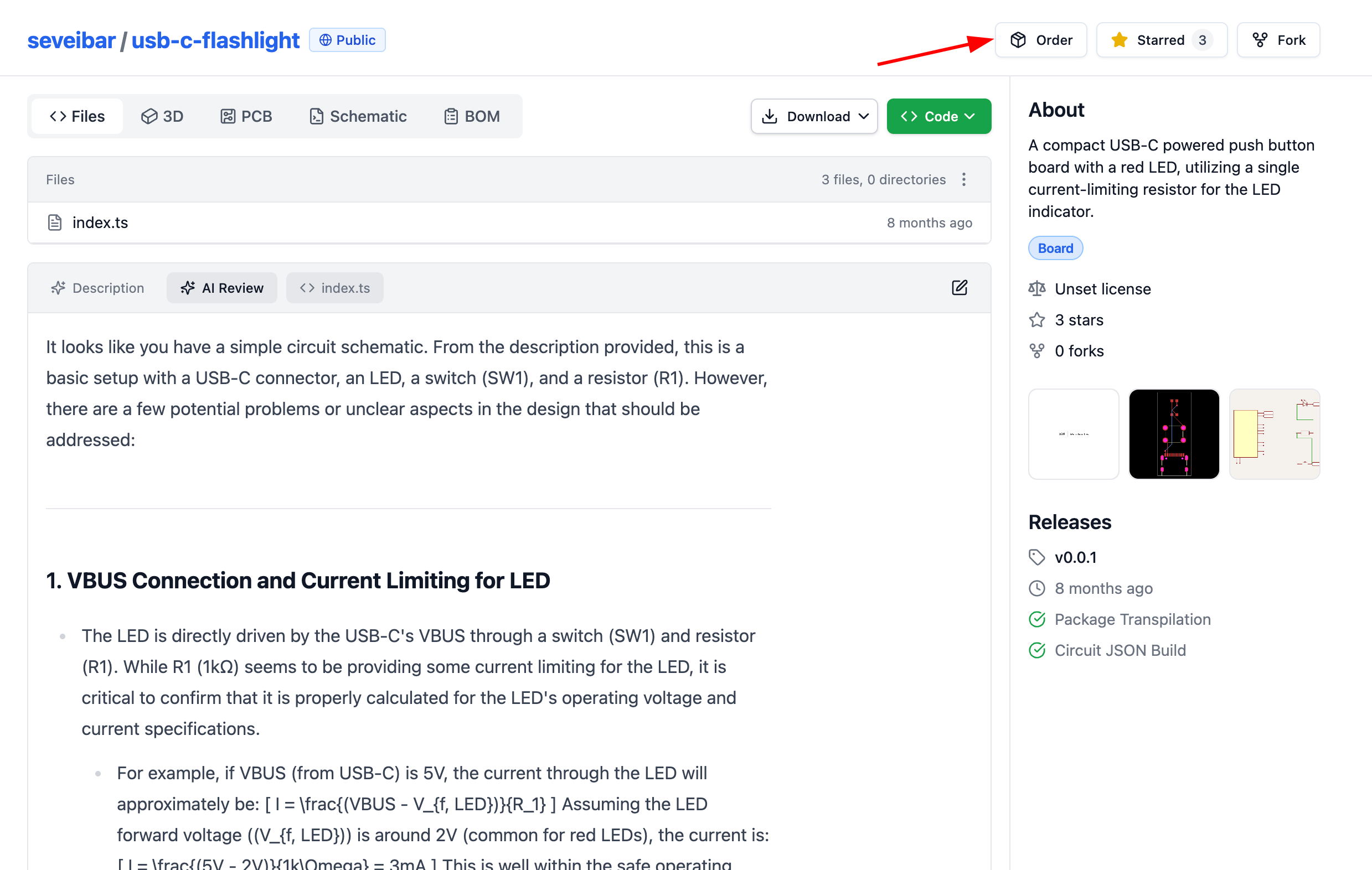

The order button is present on your project's view packages page

### 2. Select Your Vendor and Quote

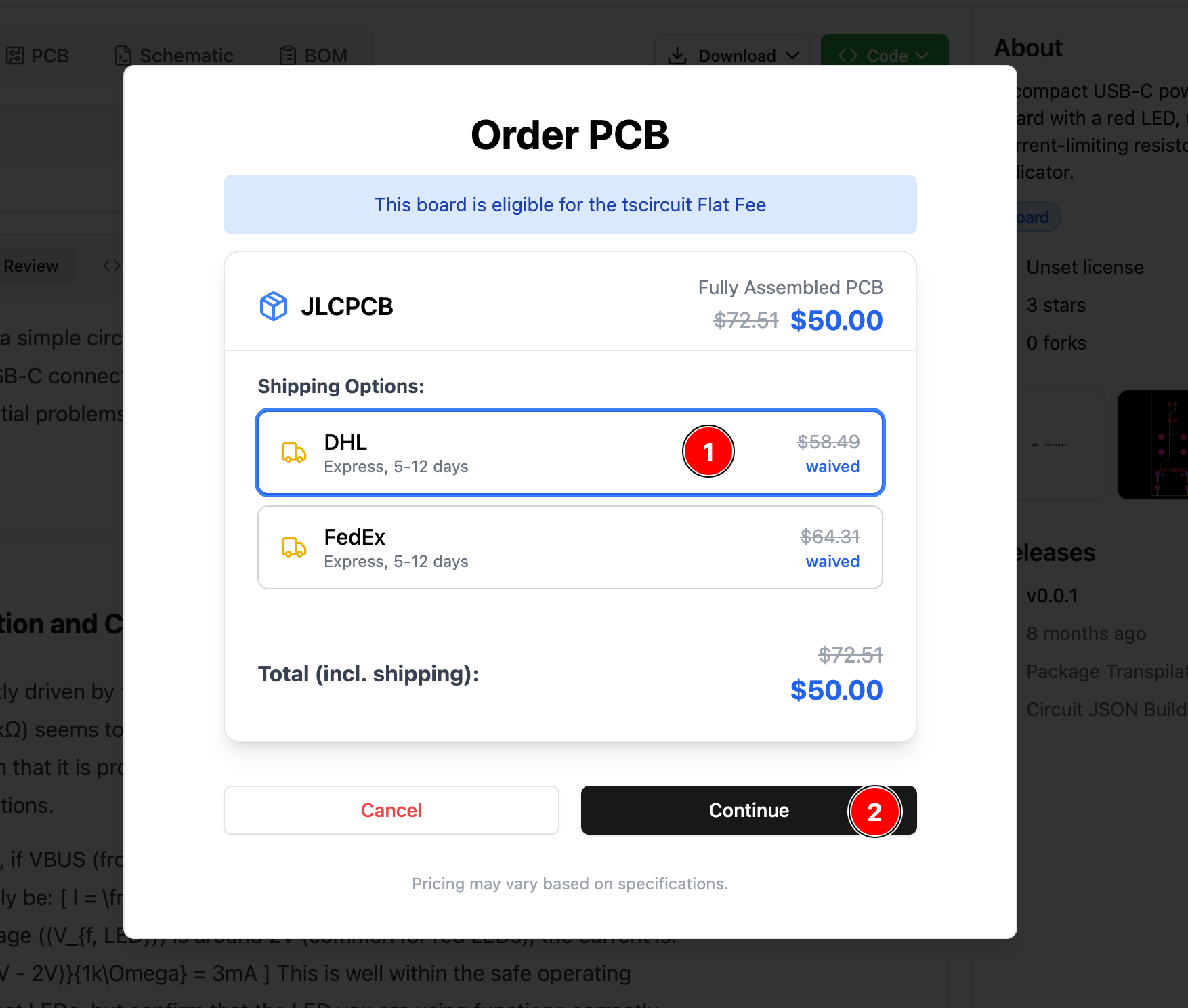

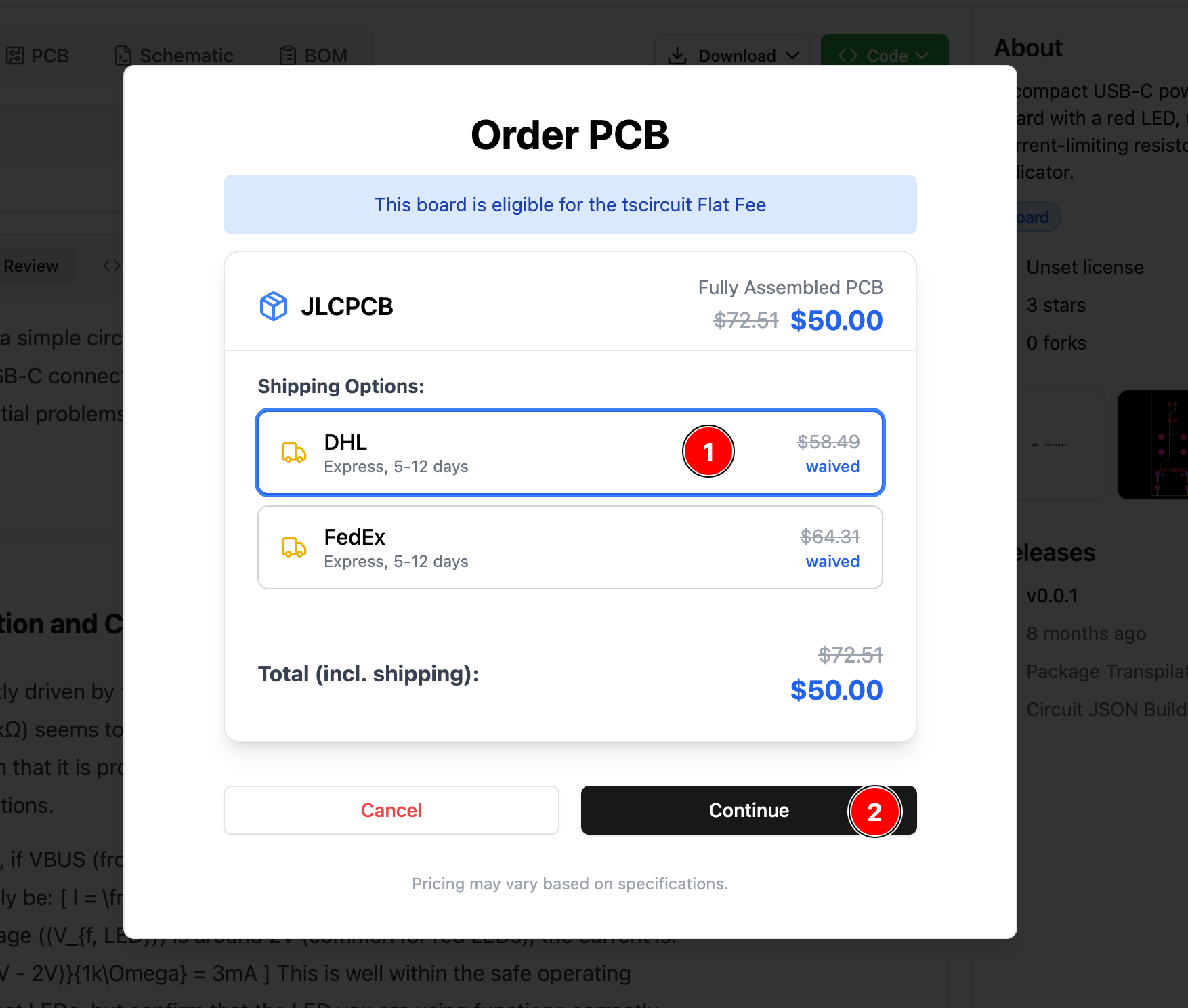

When you click the order button, a dialog will appear showing quotes from different vendors. Currently, JLCPCB is the only available vendor, with more vendors coming soon. Compare the prices, lead times, and shipping options, then select your preferred vendor and click continue.

The order button is present on your project's view packages page

### 2. Select Your Vendor and Quote

When you click the order button, a dialog will appear showing quotes from different vendors. Currently, JLCPCB is the only available vendor, with more vendors coming soon. Compare the prices, lead times, and shipping options, then select your preferred vendor and click continue.

Compare quotes from multiple vendors and select the best option for your needs

### 3. Complete Your Order

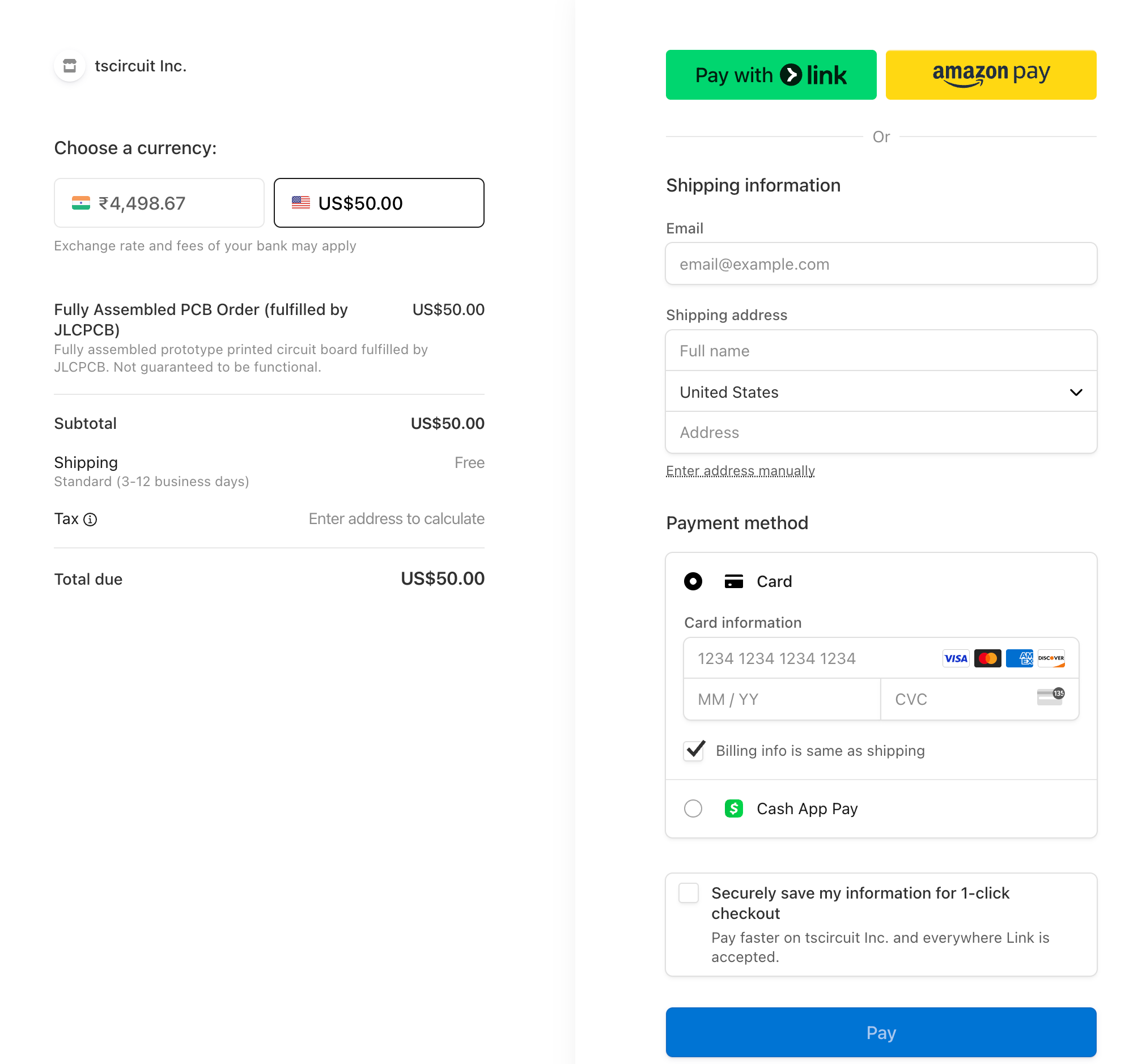

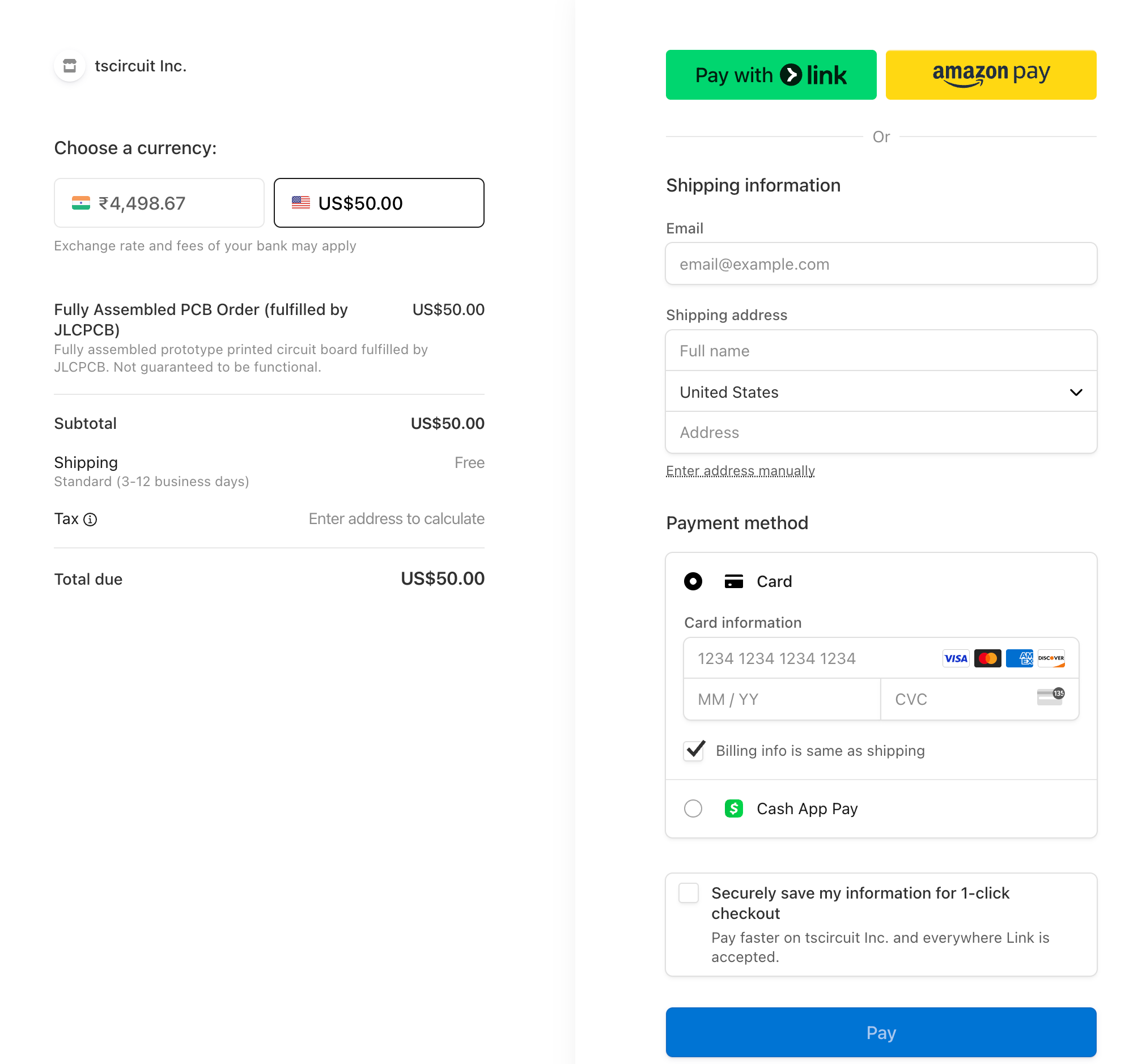

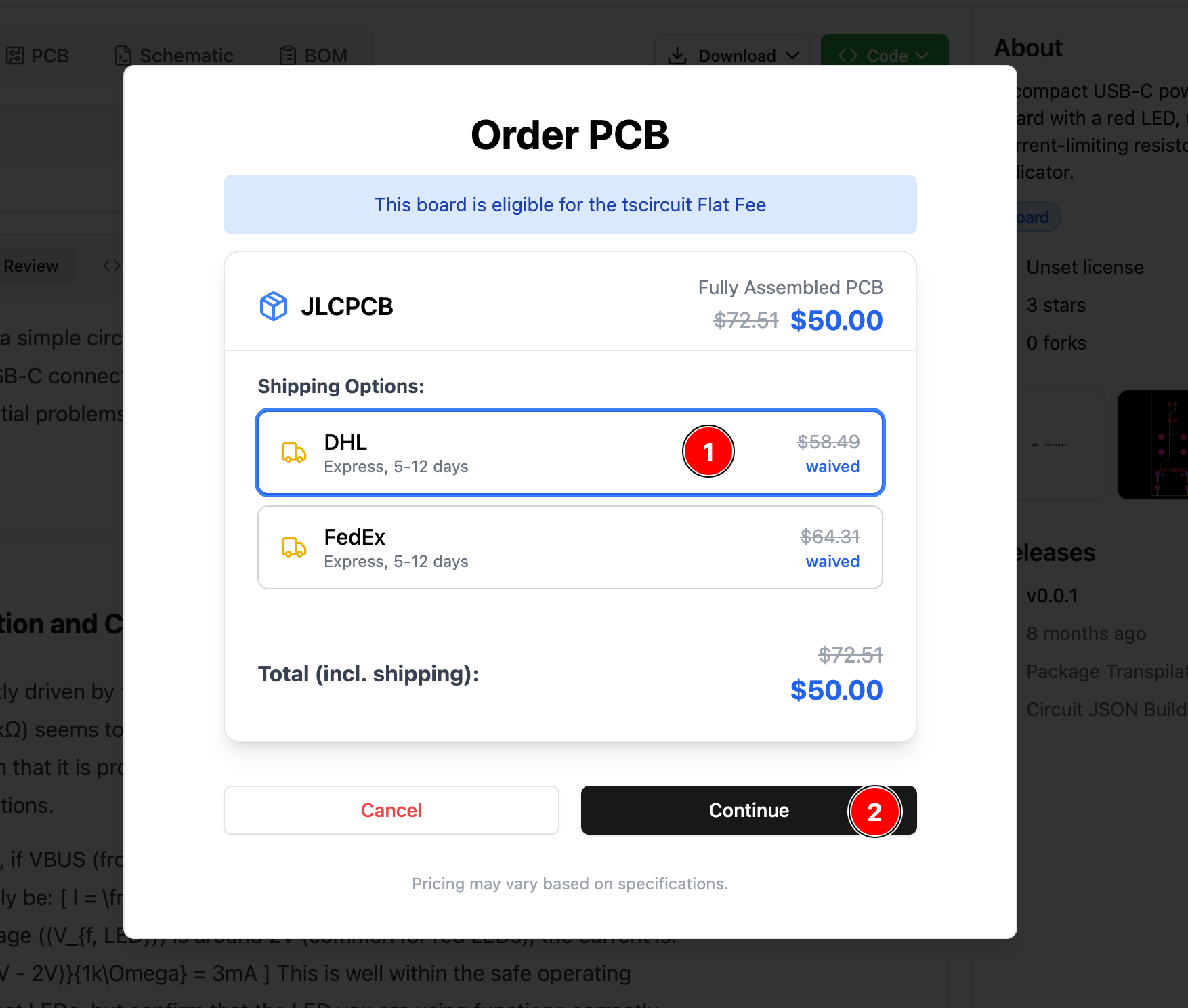

Finally, you'll be redirected to a secure Stripe checkout page where you can enter your payment details and shipping address. Your PCB will be delivered directly to your specified address.

Compare quotes from multiple vendors and select the best option for your needs

### 3. Complete Your Order

Finally, you'll be redirected to a secure Stripe checkout page where you can enter your payment details and shipping address. Your PCB will be delivered directly to your specified address.

Secure checkout with Stripe handles payment and shipping details

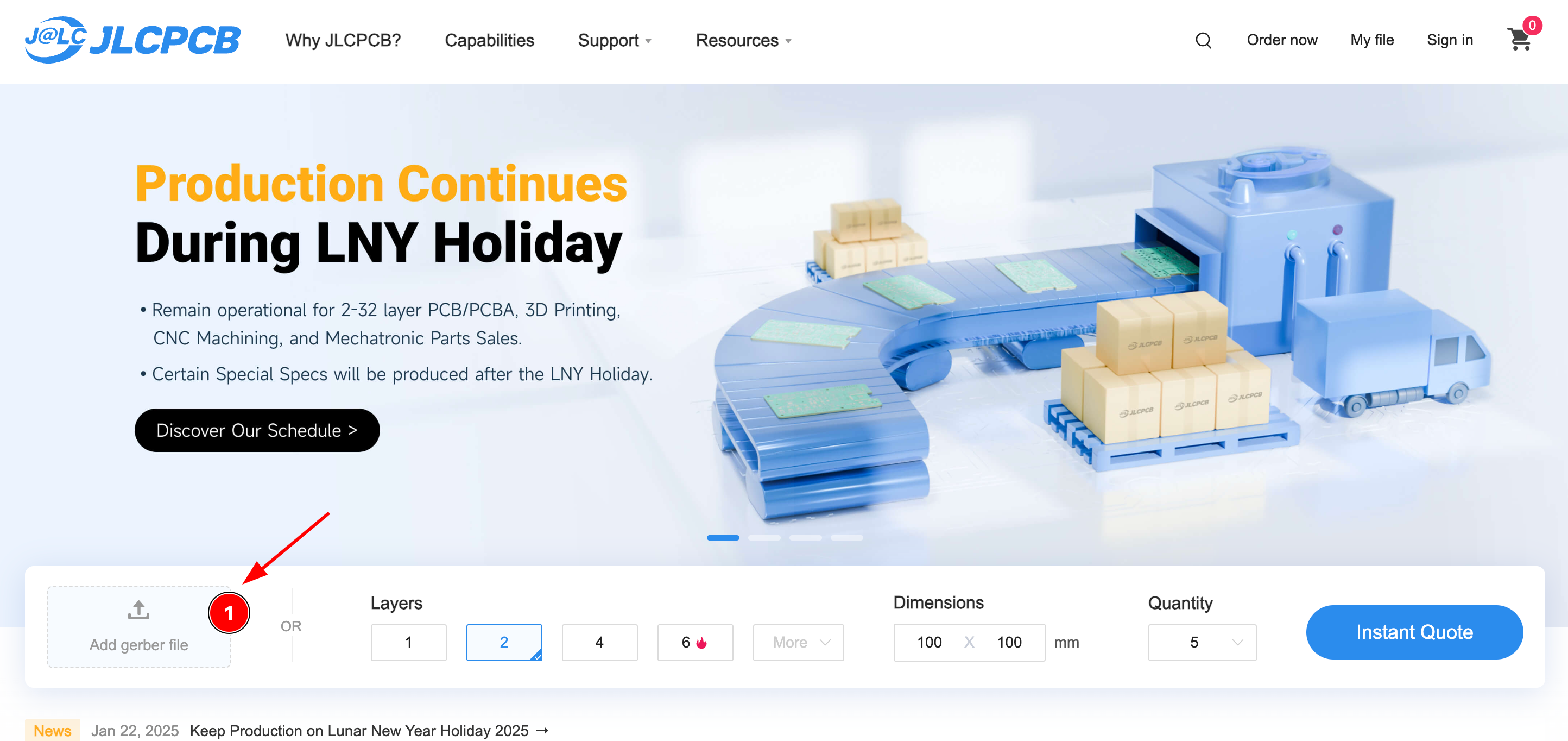

## Uploading [Fabrication Files](../guides/understanding-fabrication-files.md)

Most fabrication or turn-key assembly services allow you to directly upload 3 types of files:

- Gerbers

- Bill of Materials (BOM CSV)

- Pick'n'Place File (CSV)

These files are all available inside your [Fabrication Files zip file](../guides/understanding-fabrication-files.md) when

you export from tscircuit.

Secure checkout with Stripe handles payment and shipping details

## Uploading [Fabrication Files](../guides/understanding-fabrication-files.md)

Most fabrication or turn-key assembly services allow you to directly upload 3 types of files:

- Gerbers

- Bill of Materials (BOM CSV)

- Pick'n'Place File (CSV)

These files are all available inside your [Fabrication Files zip file](../guides/understanding-fabrication-files.md) when

you export from tscircuit.

Many fabricators allow you to directly drop fabrication files on their website!

## Assembling your own boards

It can sometimes be easier to assemble your own boards, this gives you more

control over your inventory and can lower the cost of your prototypes since

assembly services often have a minimum order quantity.

Even if you're assembling your own board, you should still order your PCB

from a fabrication service. PCBs require a chemical etching process to do

at home and it's rarely worth the hassle to do it yourself.

When you're assembling your own board, you can create a printout of your

Assembly View to make it easier to place components. In an assembly view,

the "pin1" location is marked with a cut corner. This can help you verify

the orientation of each component as you place it.

Many fabricators allow you to directly drop fabrication files on their website!

## Assembling your own boards

It can sometimes be easier to assemble your own boards, this gives you more

control over your inventory and can lower the cost of your prototypes since

assembly services often have a minimum order quantity.

Even if you're assembling your own board, you should still order your PCB

from a fabrication service. PCBs require a chemical etching process to do

at home and it's rarely worth the hassle to do it yourself.

When you're assembling your own board, you can create a printout of your

Assembly View to make it easier to place components. In an assembly view,

the "pin1" location is marked with a cut corner. This can help you verify

the orientation of each component as you place it.

## Controlling Part Selection

Before placing your order, there are two important component properties that affect the ordering process. The `supplierPartNumbers` prop allows you to specify exact part numbers from suppliers, helping to ensure the correct components are selected during ordering. This is particularly useful for specific or critical components.

```tsx

```

## Do Not Place Components

Components with the `doNotPlace` prop set to `true` will not be included in the parts selection for ordering. This is useful for components that you plan to solder manually or that are not available through the supplier.

```tsx

```

---

title: What are electronics made of?

sidebar_position: 1

description: >-

In this tutorial, we're going to be talking about the different elements that

make up a Printed Circuit Board (PCB). For each element, we'll show different

ways that the element can be represented in tscircuit.

---

## Overview

In this tutorial, we're going to be talking about the different elements that

make up a Printed Circuit Board (PCB). For each element, we'll show different

ways that the element can be represented in tscircuit.

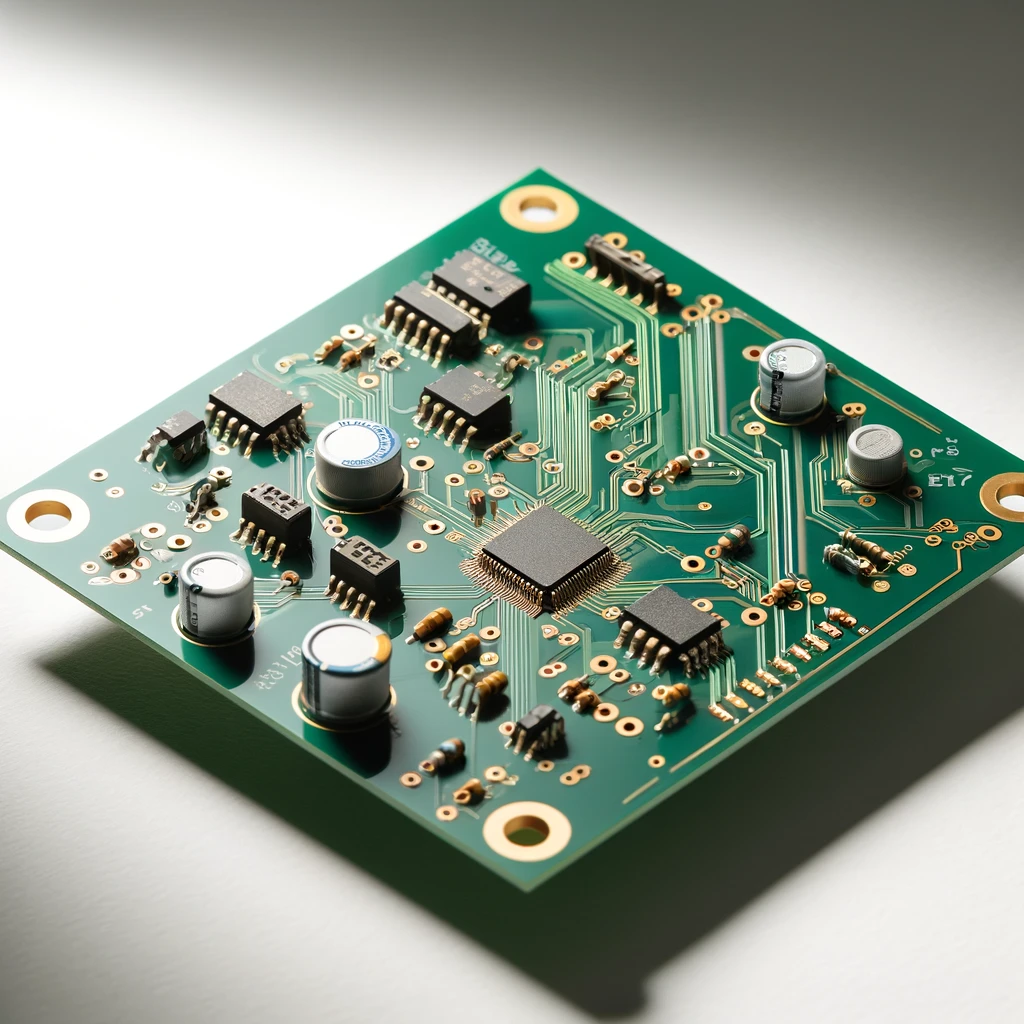

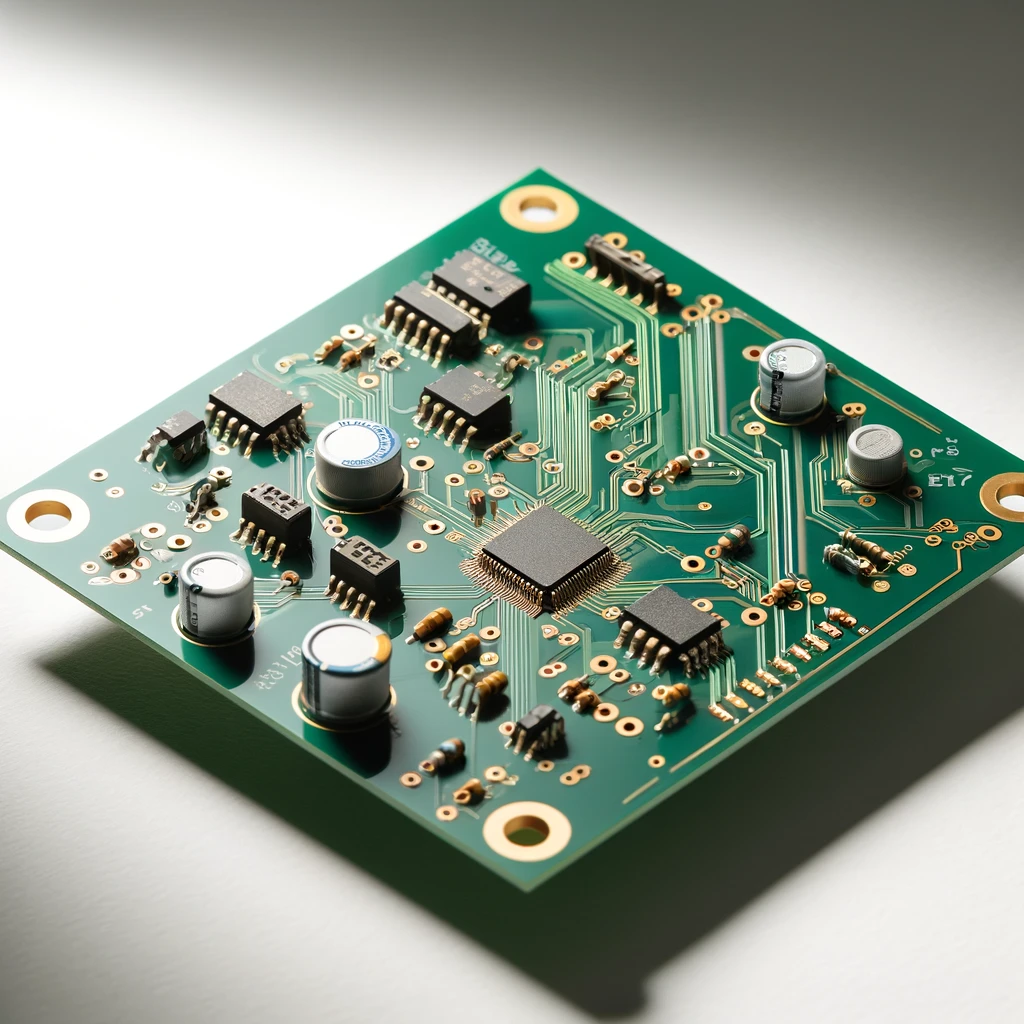

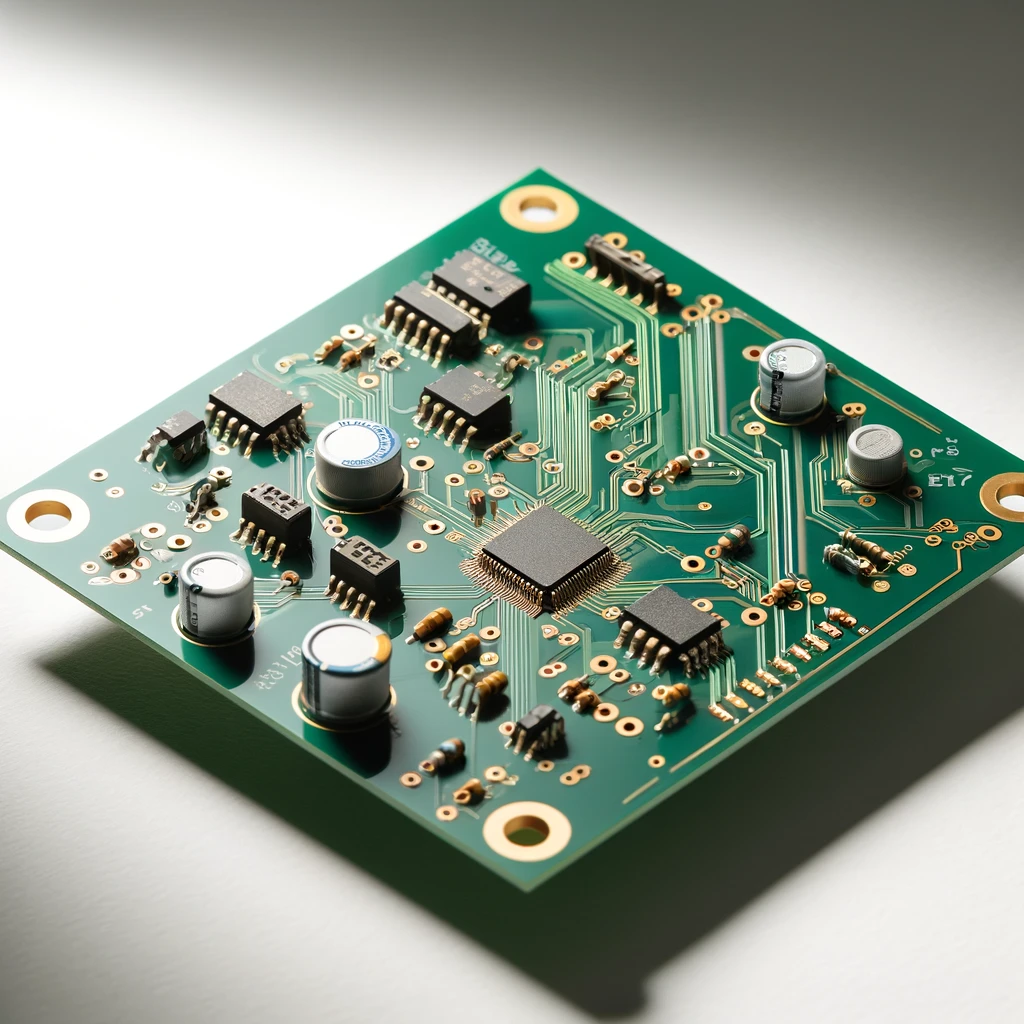

## What is copper? Why are PCBs green?

Copper is a conductive material that's used on a PCB to make an electrical

connection between chips. A PCB is mostly made up of fiberglass with a small

layer of precisely etched copper. The fiberglass is non-conductive and often

coated with non-conductive green "soldermask" to cover parts of the copper that

aren't meant to be connected to chips.

## Controlling Part Selection

Before placing your order, there are two important component properties that affect the ordering process. The `supplierPartNumbers` prop allows you to specify exact part numbers from suppliers, helping to ensure the correct components are selected during ordering. This is particularly useful for specific or critical components.

```tsx

```

## Do Not Place Components

Components with the `doNotPlace` prop set to `true` will not be included in the parts selection for ordering. This is useful for components that you plan to solder manually or that are not available through the supplier.

```tsx

```

---

title: What are electronics made of?

sidebar_position: 1

description: >-

In this tutorial, we're going to be talking about the different elements that

make up a Printed Circuit Board (PCB). For each element, we'll show different

ways that the element can be represented in tscircuit.

---

## Overview

In this tutorial, we're going to be talking about the different elements that

make up a Printed Circuit Board (PCB). For each element, we'll show different

ways that the element can be represented in tscircuit.

## What is copper? Why are PCBs green?

Copper is a conductive material that's used on a PCB to make an electrical

connection between chips. A PCB is mostly made up of fiberglass with a small

layer of precisely etched copper. The fiberglass is non-conductive and often

coated with non-conductive green "soldermask" to cover parts of the copper that

aren't meant to be connected to chips.

An AI-generated PCB image. All the yellow parts represent copper, while the green parts represent fiberglass with a green soldermask

A PCB can be thought of as a bunch of "printed" copper separated by fiberglass

sections that "insulate" or don't conduct electricity. We "glue" (solder) chips

to the copper "pads" to add them to the circuit.

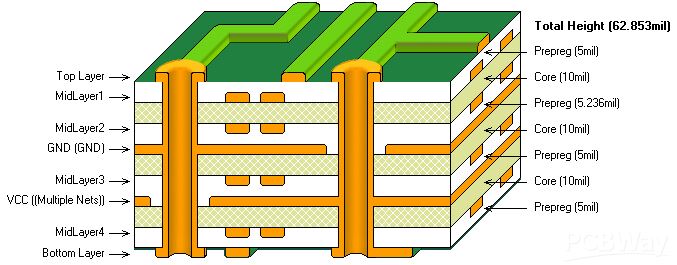

## What are PCB layers?

When you print on a piece of paper, you can print "single-sided" or "double-sided",

PCBs can also be printed singled-sided or double-sided! The "front" of the PCB

is called the "top" layer, and the "back" of the PCB is called the "bottom" layer.

We can "print" copper to each of these layers to draw lots of wires and connect

lots of chips. Sometimes a wire needs to "go over"/"go under" another wire

because the wires aren't allowed to cross. When this happens, we can use the

"back" or "bottom layer" of the PCB to draw the wire so that the wires don't

accidentally touch.

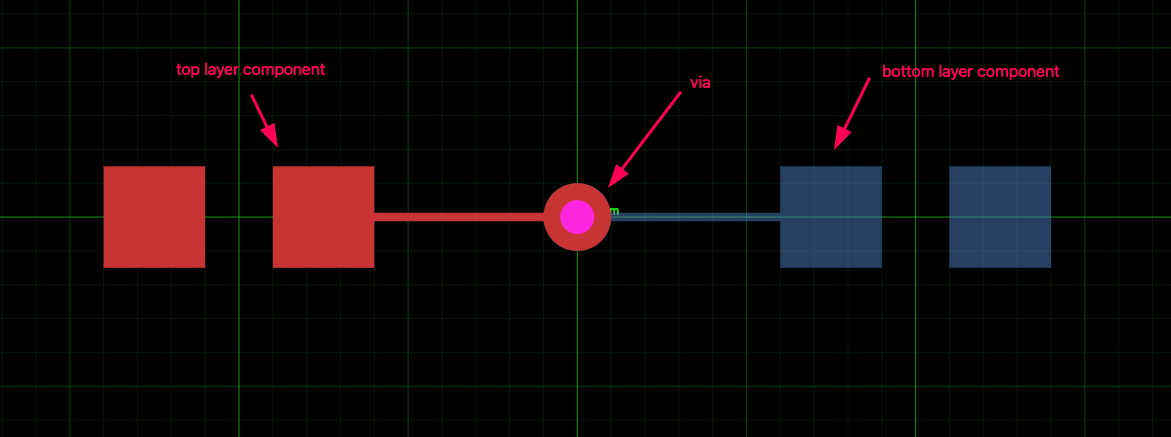

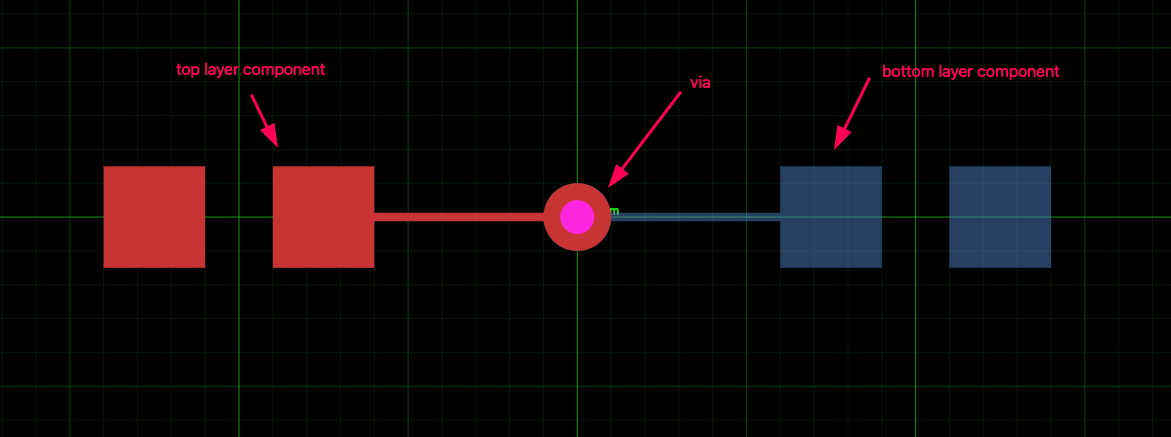

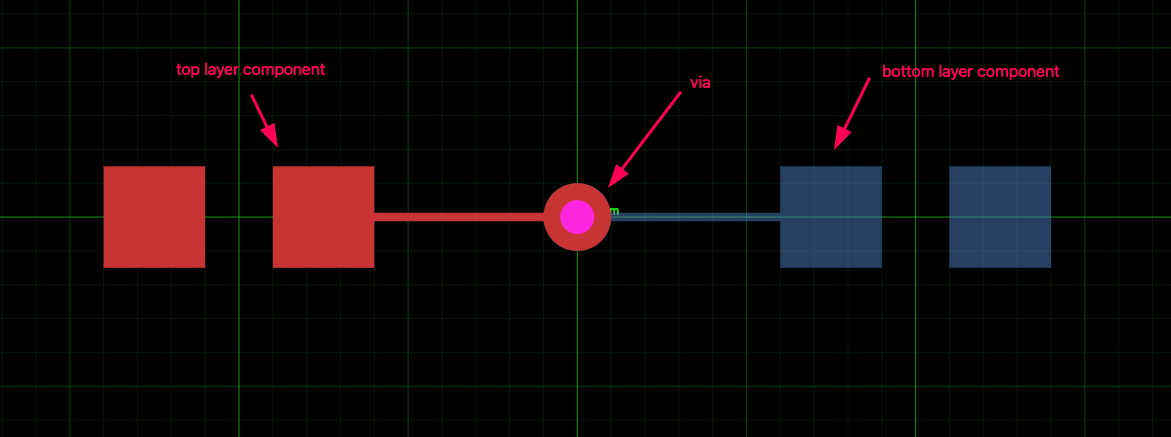

## Vias

Vias are holes that connect different layers of PCB. Let's say you have a chip

on the top layer of a PCB and the back layer of a PCB. How can you connect them?

The copper on the top needs some way to "pass through" to the bottom layer.

This is where vias come in. A via is a hole that is "filled with copper" so that

the top layer can pass to the bottom.

An AI-generated PCB image. All the yellow parts represent copper, while the green parts represent fiberglass with a green soldermask

A PCB can be thought of as a bunch of "printed" copper separated by fiberglass

sections that "insulate" or don't conduct electricity. We "glue" (solder) chips

to the copper "pads" to add them to the circuit.

## What are PCB layers?

When you print on a piece of paper, you can print "single-sided" or "double-sided",

PCBs can also be printed singled-sided or double-sided! The "front" of the PCB

is called the "top" layer, and the "back" of the PCB is called the "bottom" layer.

We can "print" copper to each of these layers to draw lots of wires and connect

lots of chips. Sometimes a wire needs to "go over"/"go under" another wire

because the wires aren't allowed to cross. When this happens, we can use the

"back" or "bottom layer" of the PCB to draw the wire so that the wires don't

accidentally touch.

## Vias

Vias are holes that connect different layers of PCB. Let's say you have a chip

on the top layer of a PCB and the back layer of a PCB. How can you connect them?

The copper on the top needs some way to "pass through" to the bottom layer.

This is where vias come in. A via is a hole that is "filled with copper" so that

the top layer can pass to the bottom.

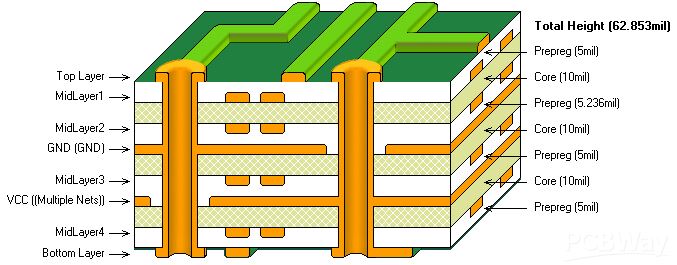

Vias connect different layers of a PCB

(

)

`} />

## Plated Holes

A plated hole is similar to a via but it's hollow so that you can push metal pins

through it. This is important for chips that have big pins that need to fit into

holes. Chips with big pins that must go through holes are called "through-hole"

chips, and chips with small

pins are called "surface-mount" chips.

(

)

`} />

## Unplated Holes "Regular Holes"

Unplated holes or "regular holes" are just holes in the printed circuit board

without any copper around them. They don't electrically connect anything, but

can be very helpful for mounting the printed circuit board.

(

)

`} />

## Traces

Traces are the wires that connect the components on a PCB. They are made of

copper and mostly covered by green soldermask so that they don't accidentally

conduct to each other if something conductive like a wire or piece of metal falls

across them.

We represent traces in PCB viewers with different colors depending on what

layer they fall on. In tscircuit, traces are always autorouted, so you don't

need to tell it which path to take- it'll automatically find one that makes sure

it doesn't cross any other traces.

Traces allow chips to "talk" to each other and for power to be shared across all

chips.

(

)

`} />

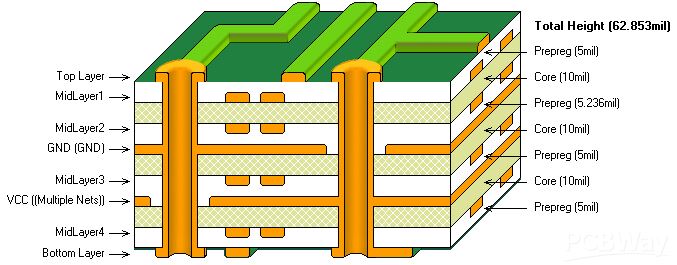

## What are inner layers?

Inner layers are layers of PCB that aren't visible, they're sandwiched on the

inside. Sometimes this is useful when you have a lot of wires to connect and

it's almost impossible to stop them from crossing each other.

Vias connect different layers of a PCB

(

)

`} />

## Plated Holes

A plated hole is similar to a via but it's hollow so that you can push metal pins

through it. This is important for chips that have big pins that need to fit into

holes. Chips with big pins that must go through holes are called "through-hole"

chips, and chips with small

pins are called "surface-mount" chips.

(

)

`} />

## Unplated Holes "Regular Holes"

Unplated holes or "regular holes" are just holes in the printed circuit board

without any copper around them. They don't electrically connect anything, but

can be very helpful for mounting the printed circuit board.

(

)

`} />

## Traces

Traces are the wires that connect the components on a PCB. They are made of

copper and mostly covered by green soldermask so that they don't accidentally

conduct to each other if something conductive like a wire or piece of metal falls

across them.

We represent traces in PCB viewers with different colors depending on what

layer they fall on. In tscircuit, traces are always autorouted, so you don't

need to tell it which path to take- it'll automatically find one that makes sure

it doesn't cross any other traces.

Traces allow chips to "talk" to each other and for power to be shared across all

chips.

(

)

`} />

## What are inner layers?

Inner layers are layers of PCB that aren't visible, they're sandwiched on the

inside. Sometimes this is useful when you have a lot of wires to connect and

it's almost impossible to stop them from crossing each other.

Inner layers are layers of PCB that aren't visible, they're sandwiched on the inside. Excellent image from pcbway

---

title: tsci add

description: Install tscircuit registry packages using the tsci add command

---

`tsci add` is the same as `npm add` or `bun add`, but defaults to the tscircuit

registry. If your project has the [tsci `.npmrc`](../web-apis/the-registry-api.md#using-the-tscircuit-npm-registry), you can just do `bun add @tsci/.`

and it has the same effect.

```

> tsci add seveibar/PICO_W

# Added @tsci/seveibar.PICO_W@0.0.1

```

You can then import the module and use it for your board!

(

)

`}

/>

---

title: tsci auth print-token

description: Print your current tscircuit API token for use with web services

---

`tsci auth print-token` prints your current tscircuit API token. This token can be used with the advanced web APIs such as the [Datasheet API](../web-apis/datasheet-api.md).

## Usage

```bash

tsci auth print-token

```

Make sure you have previously logged in with [`tsci login`](./tsci-login.md). The command will output a token string that you can pass in the `Authorization: Bearer ` header of API requests.

---

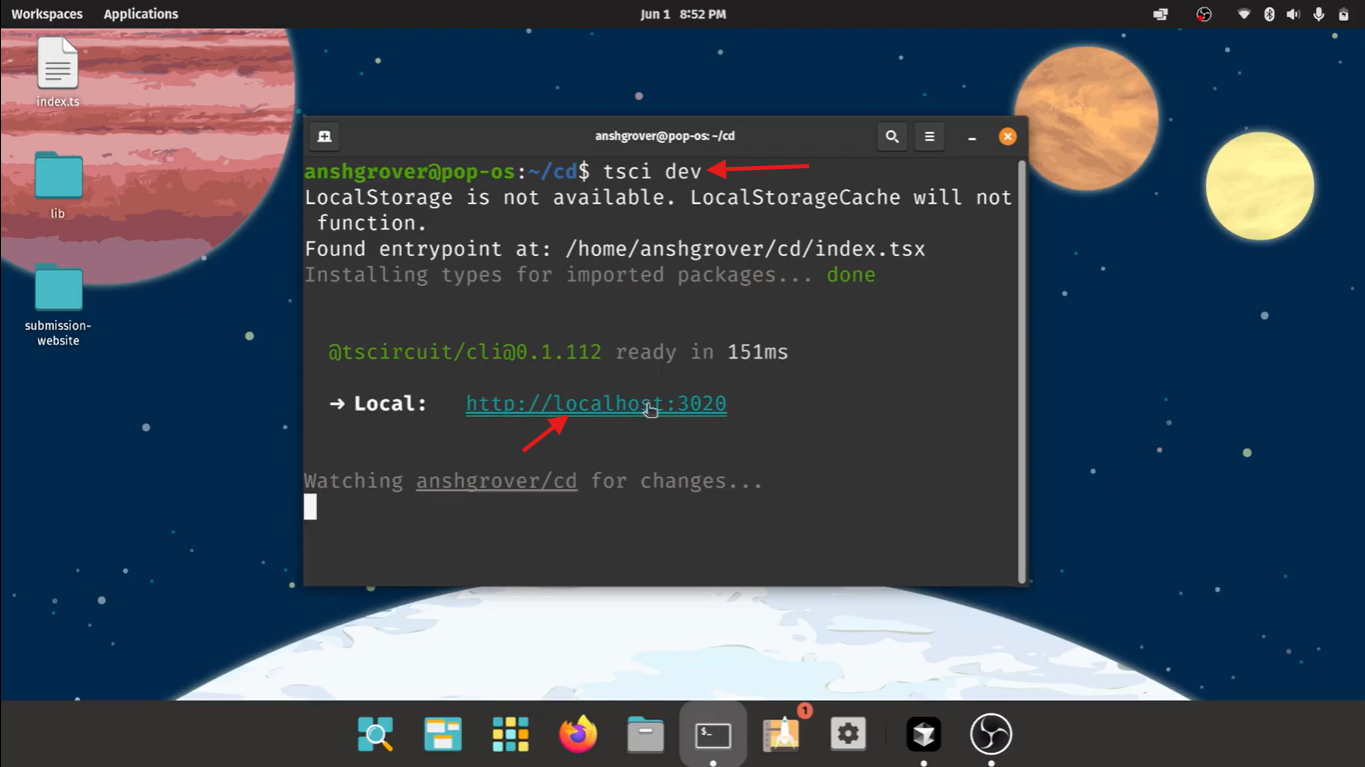

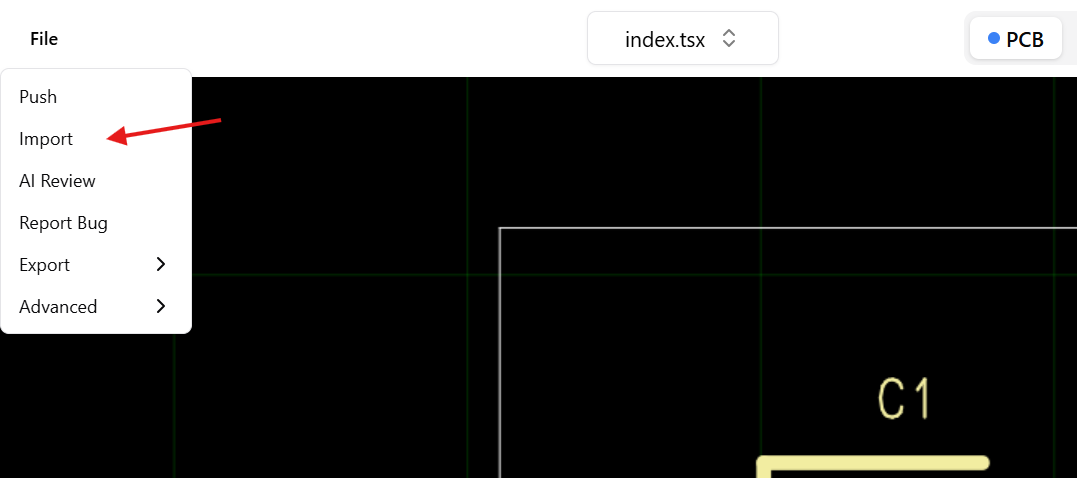

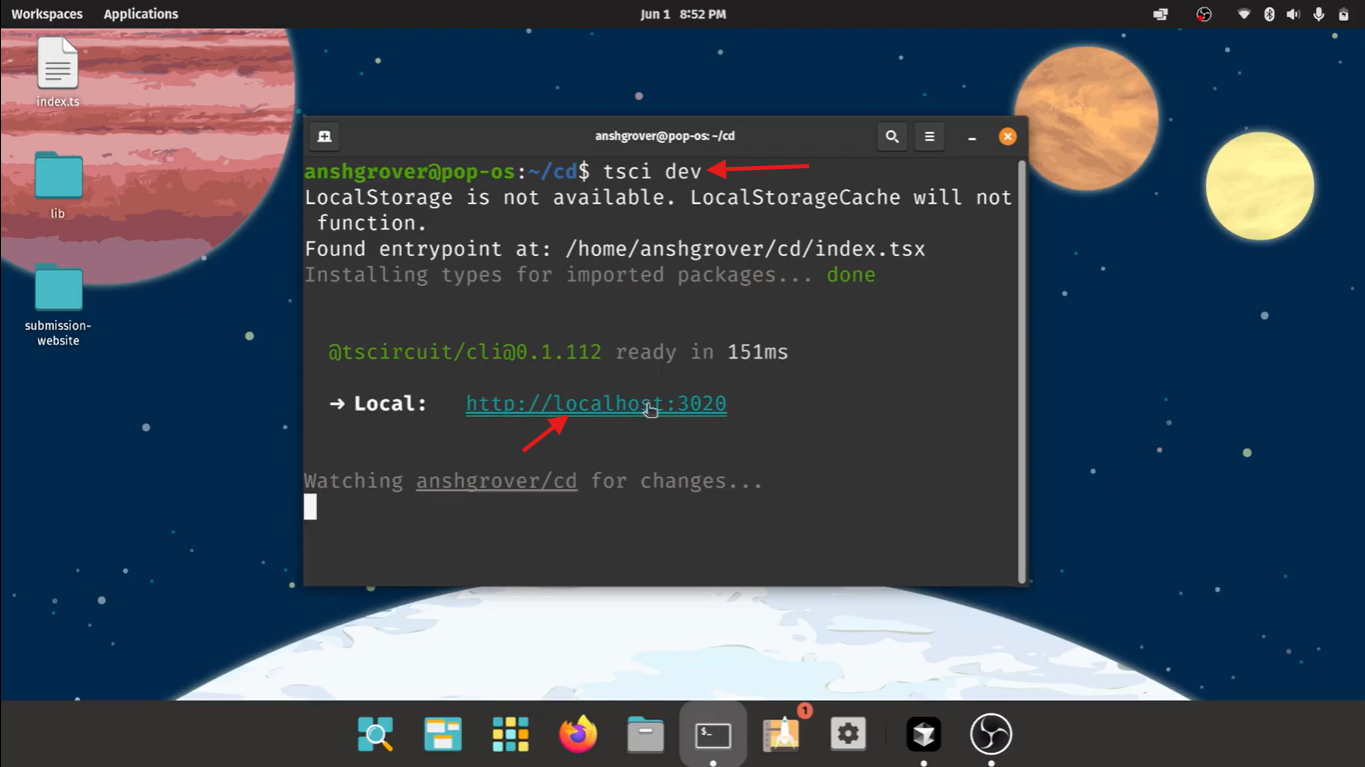

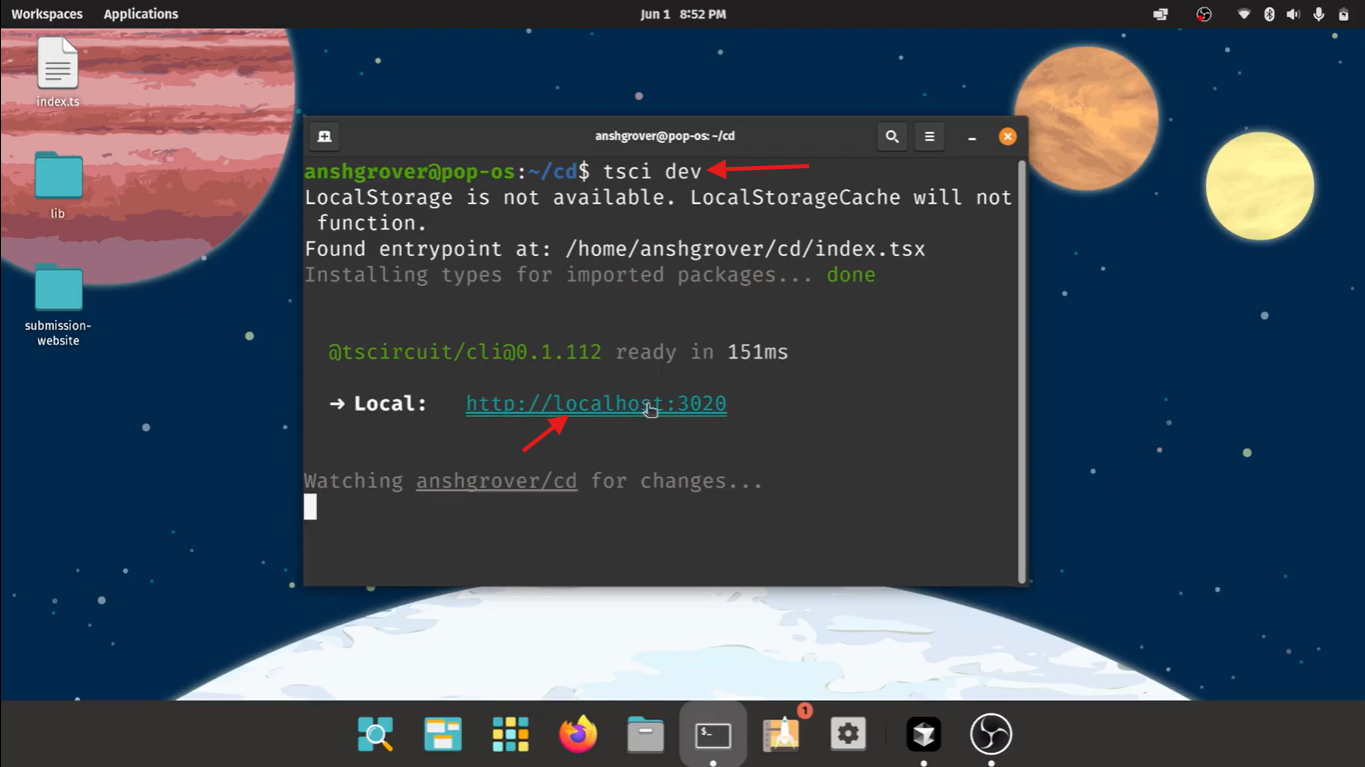

title: tsci dev

description: Run a local preview server for your tscircuit project

sidebar_position: 2

---

`tsci dev` runs a web server that lets you see a preview of your electronics

in your web browser.

After you run `tsci dev` you should see a preview of your entrypoint file in

your web browser on https://localhost:3020

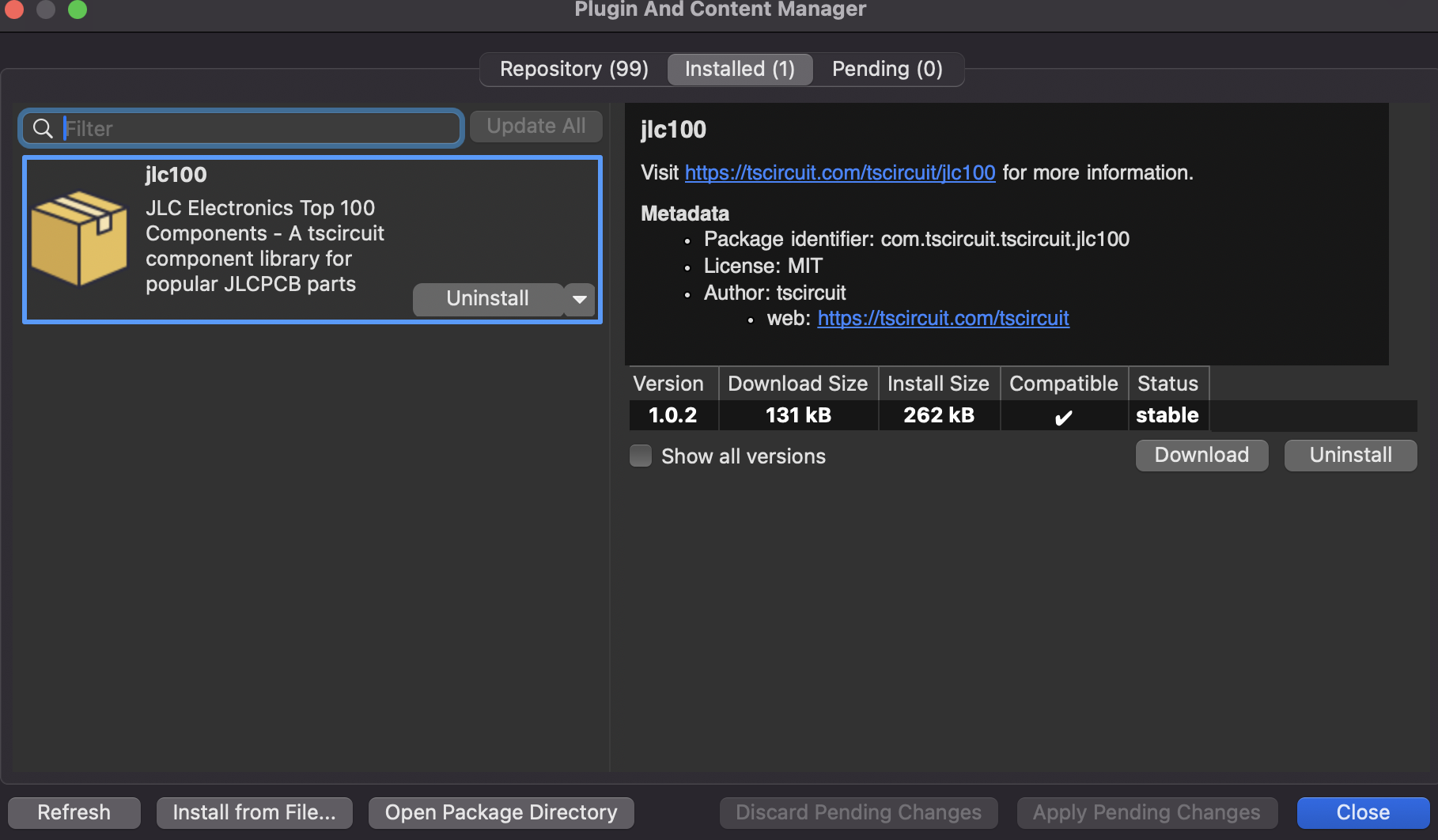

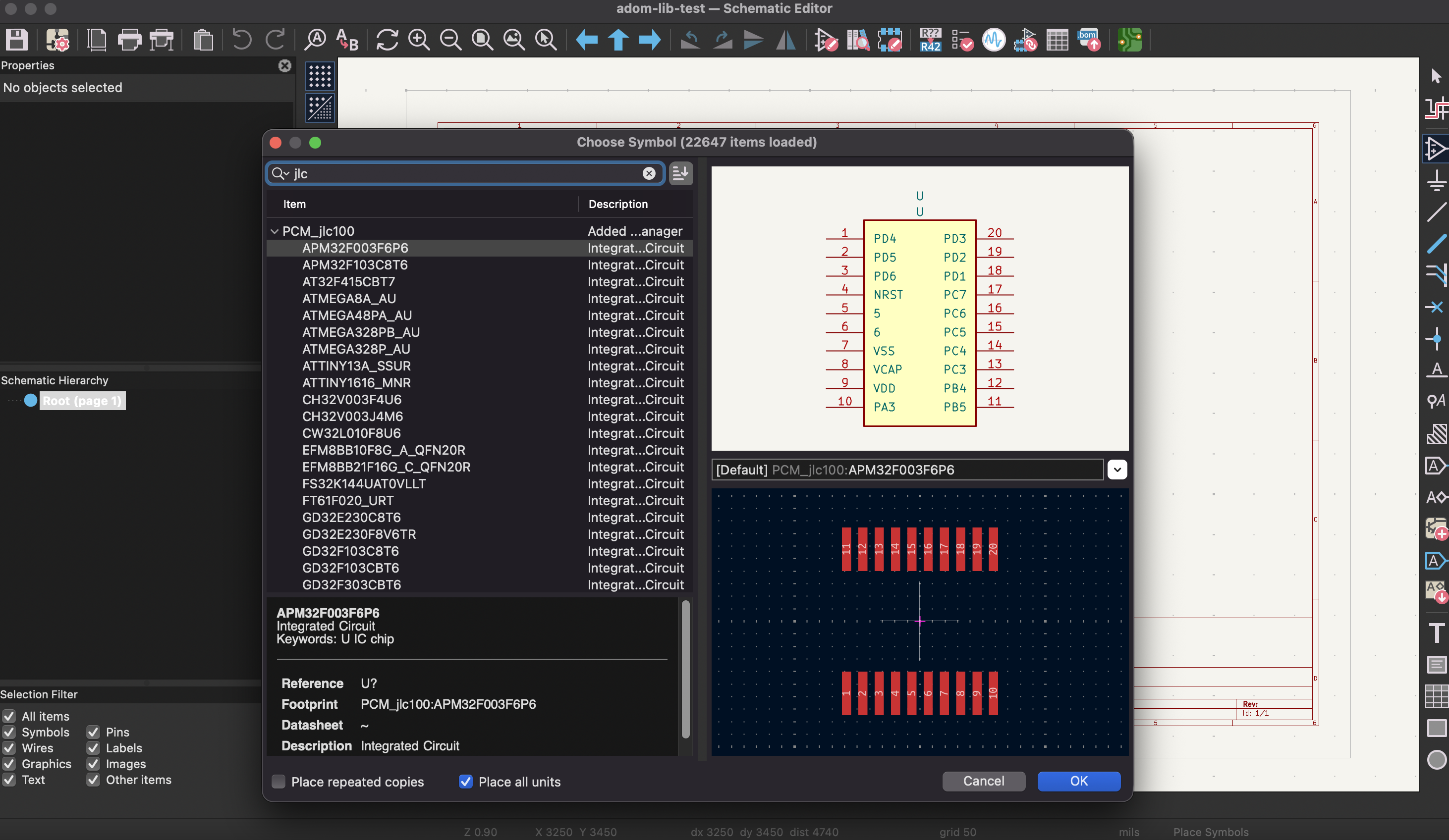

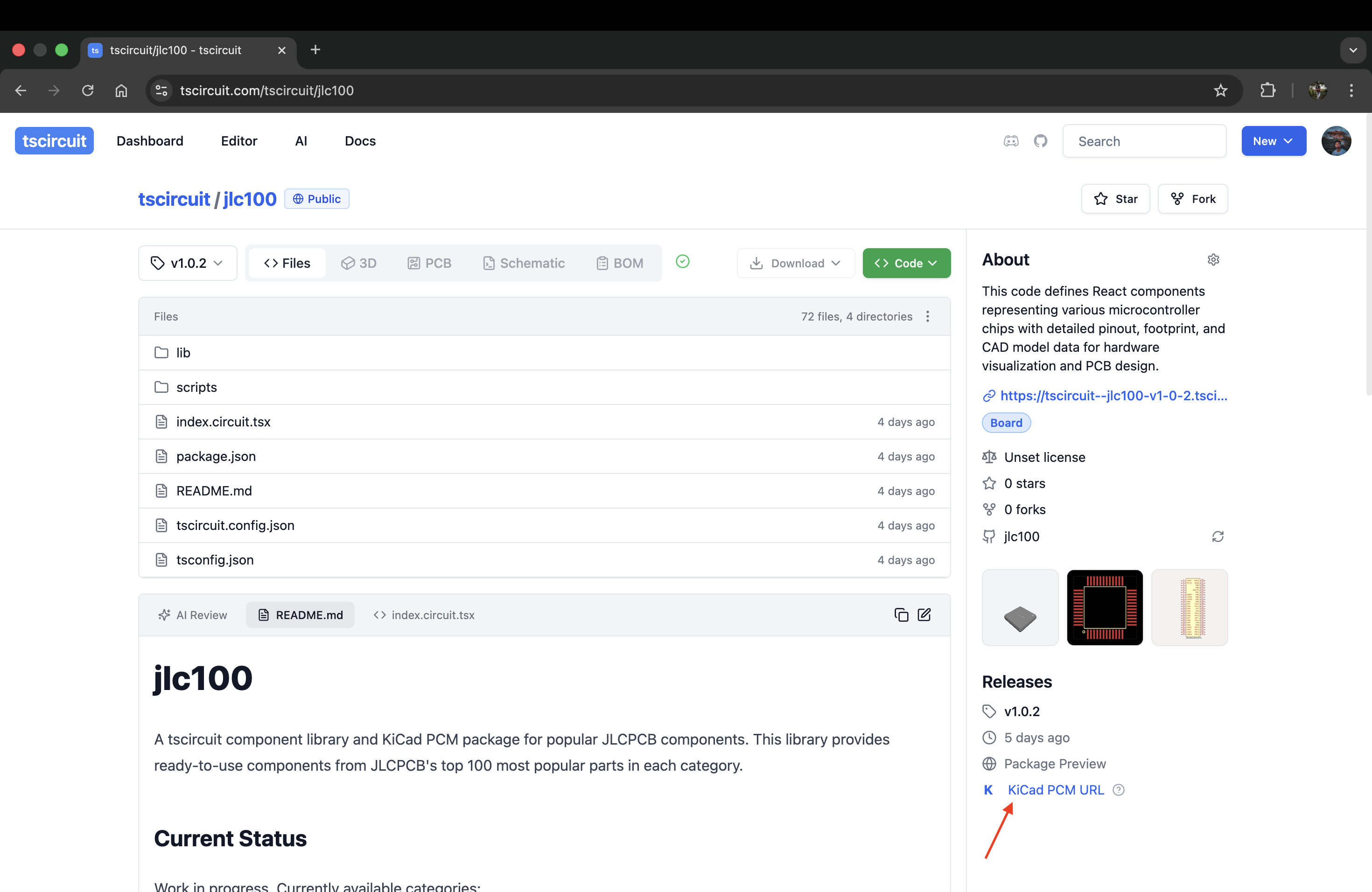

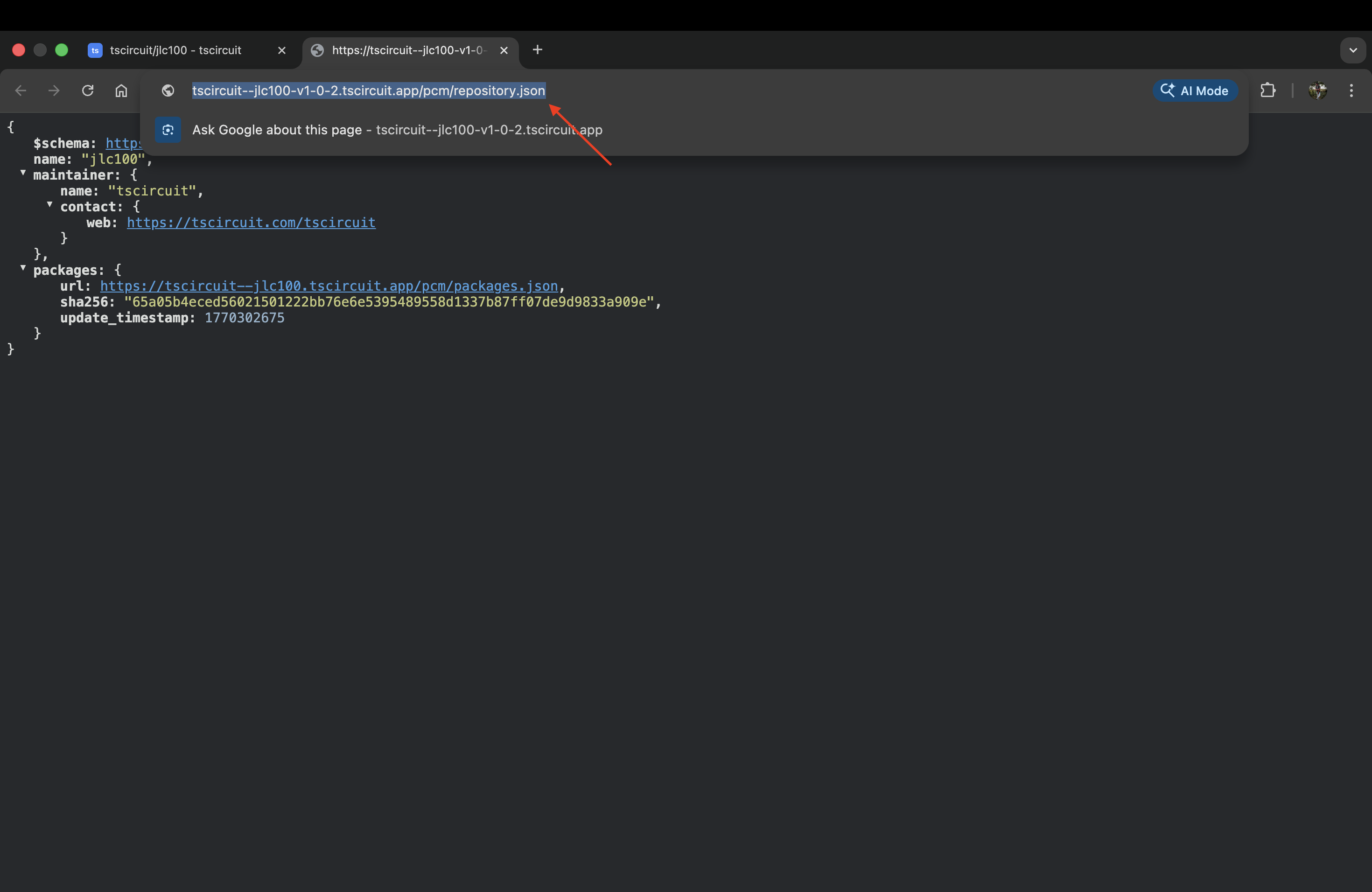

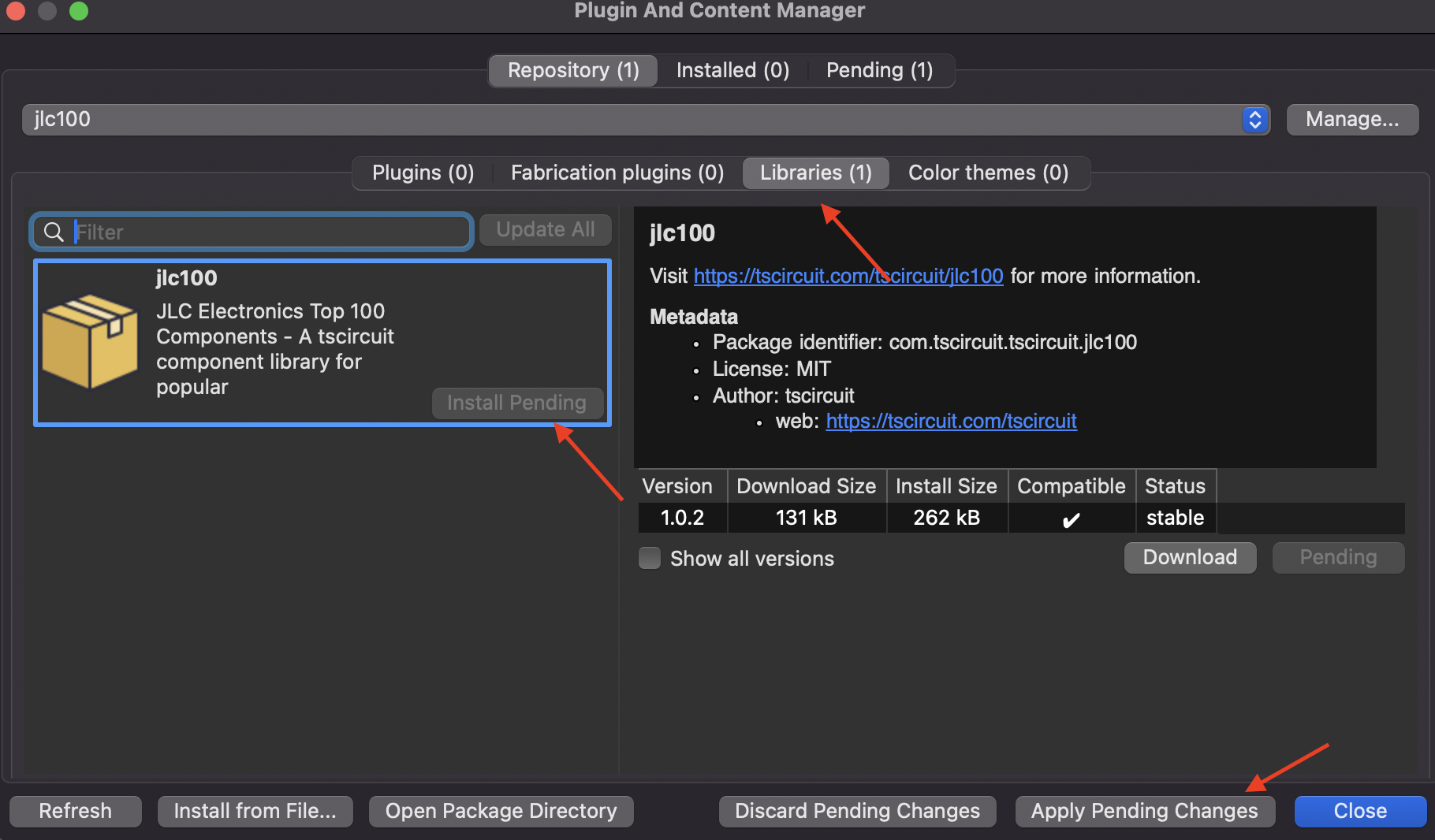

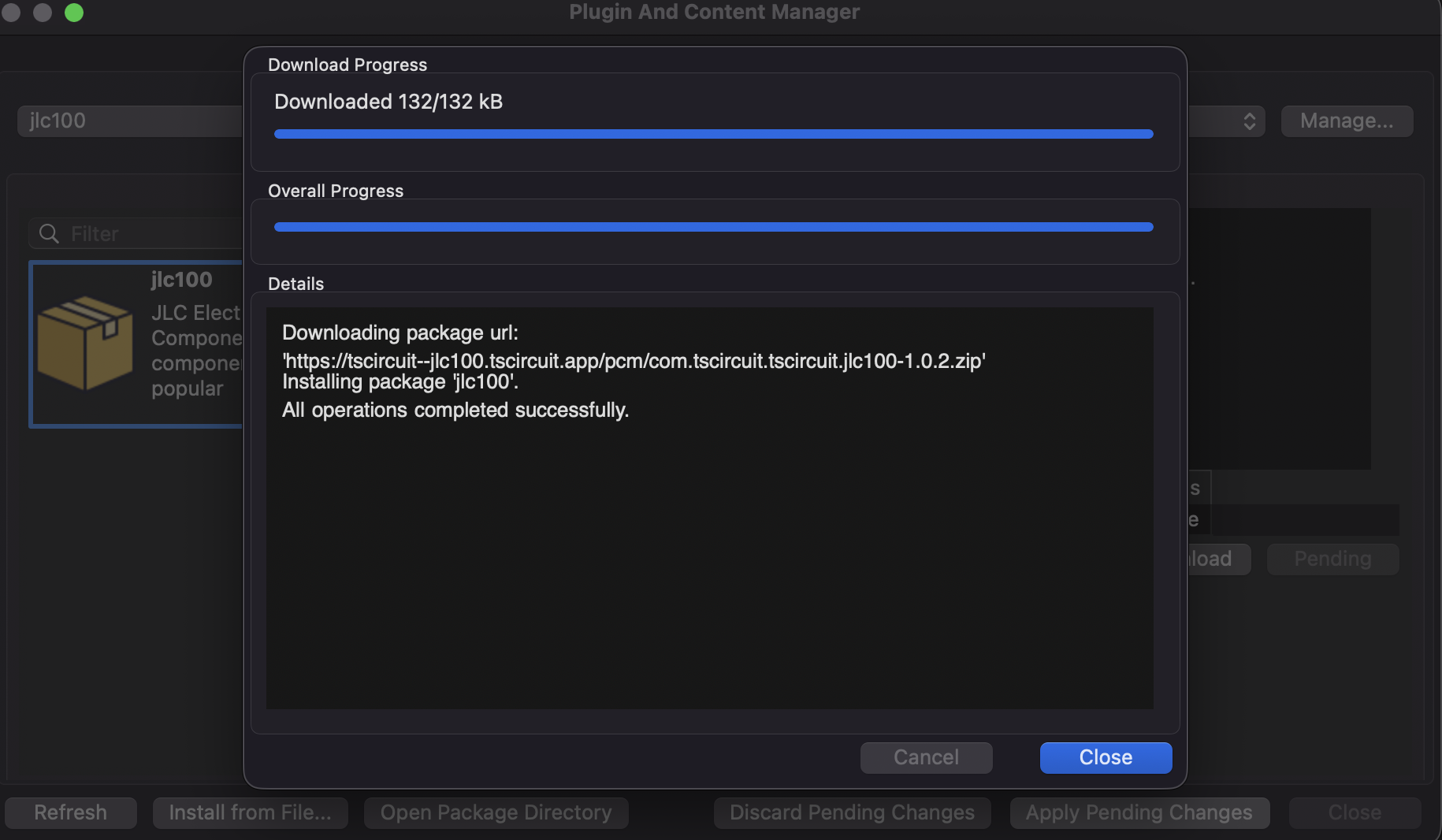

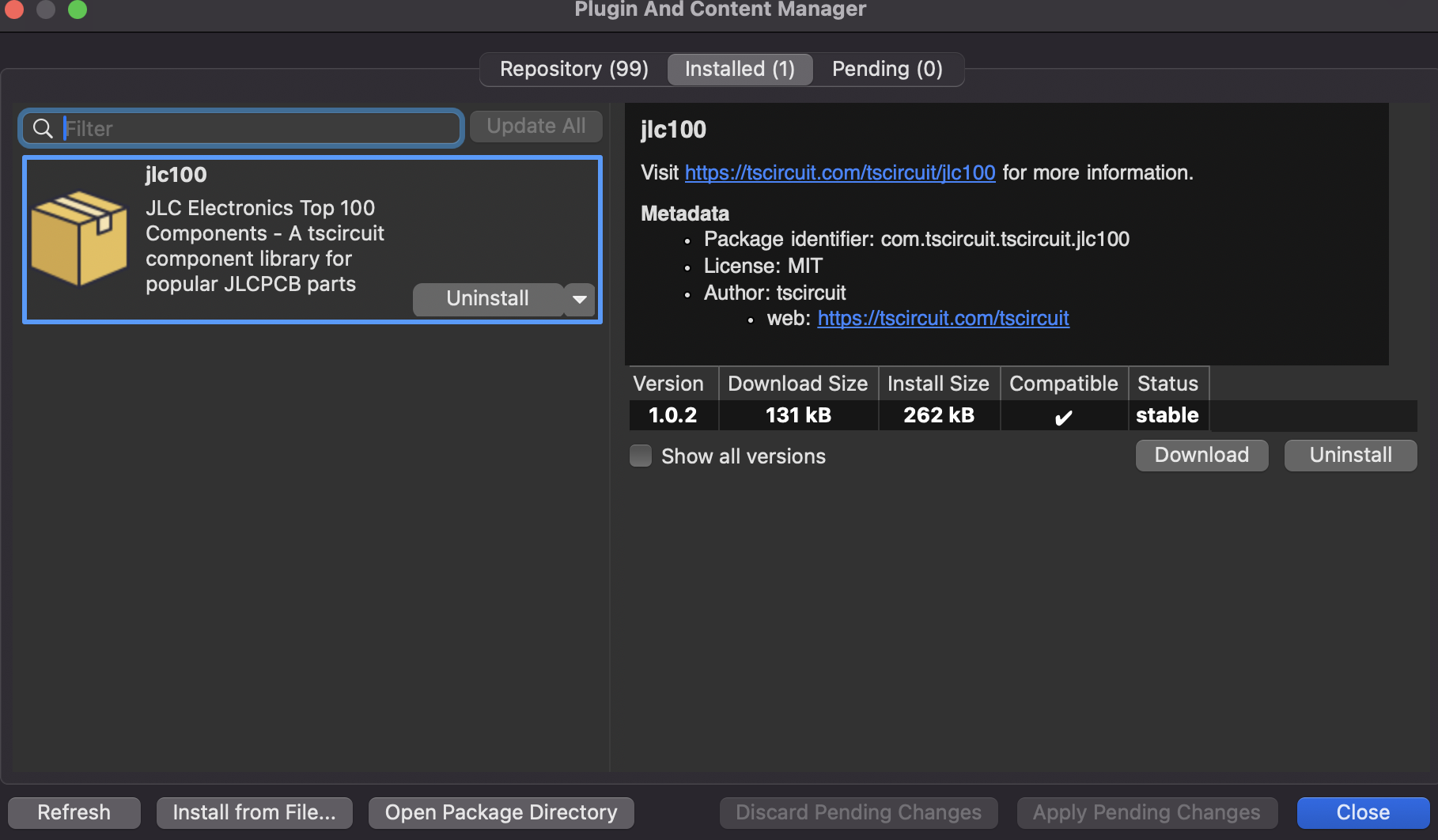

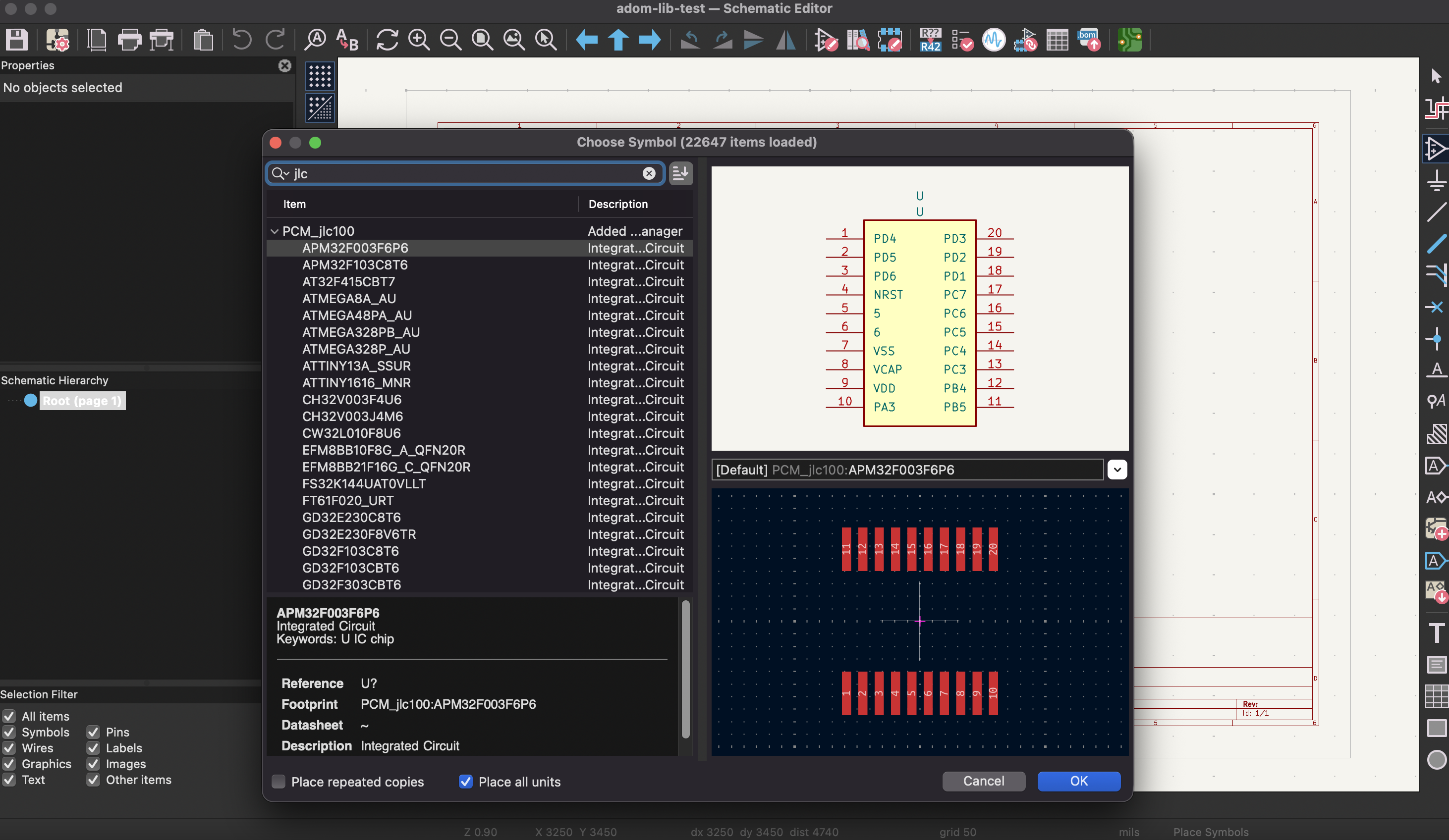

## KiCad PCM Server

The `--kicad-pcm` flag starts a KiCad Plugin and Content Manager (PCM) server in

the background alongside the development server. This allows you to install your

tscircuit components directly into KiCad as a library.

```bash

tsci dev --kicad-pcm

```

Example output:

```

➜ library tsci dev --kicad-pcm

@tscircuit/cli@0.1.851 ready in 1067ms

➜ Local: http://localhost:3023/#file=lib%2Findex.ts

Watching "my-project" for changes...

➜ Auto-updating KiCad PCM Server: http://localhost:3023/pcm/repository.json

```

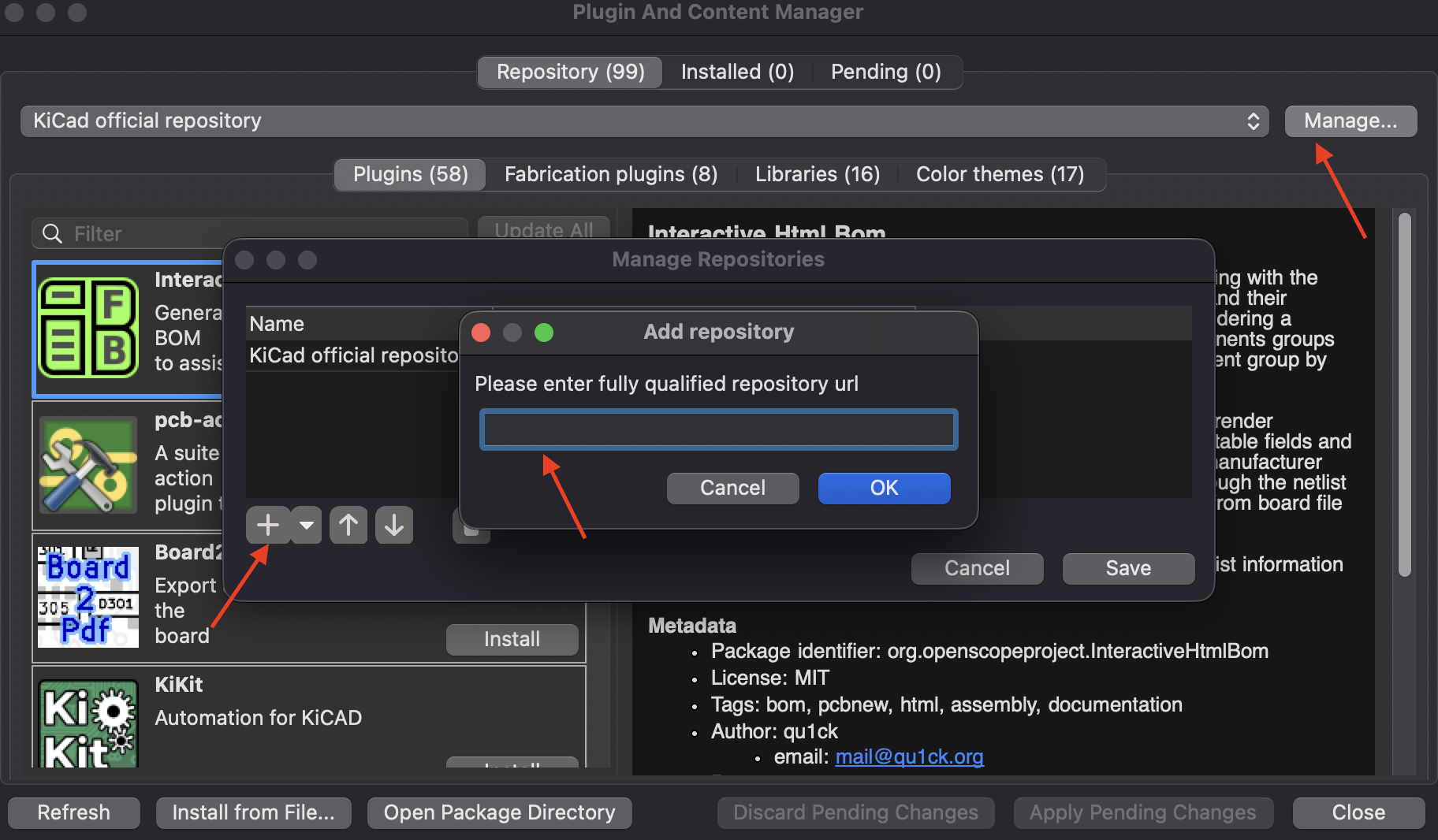

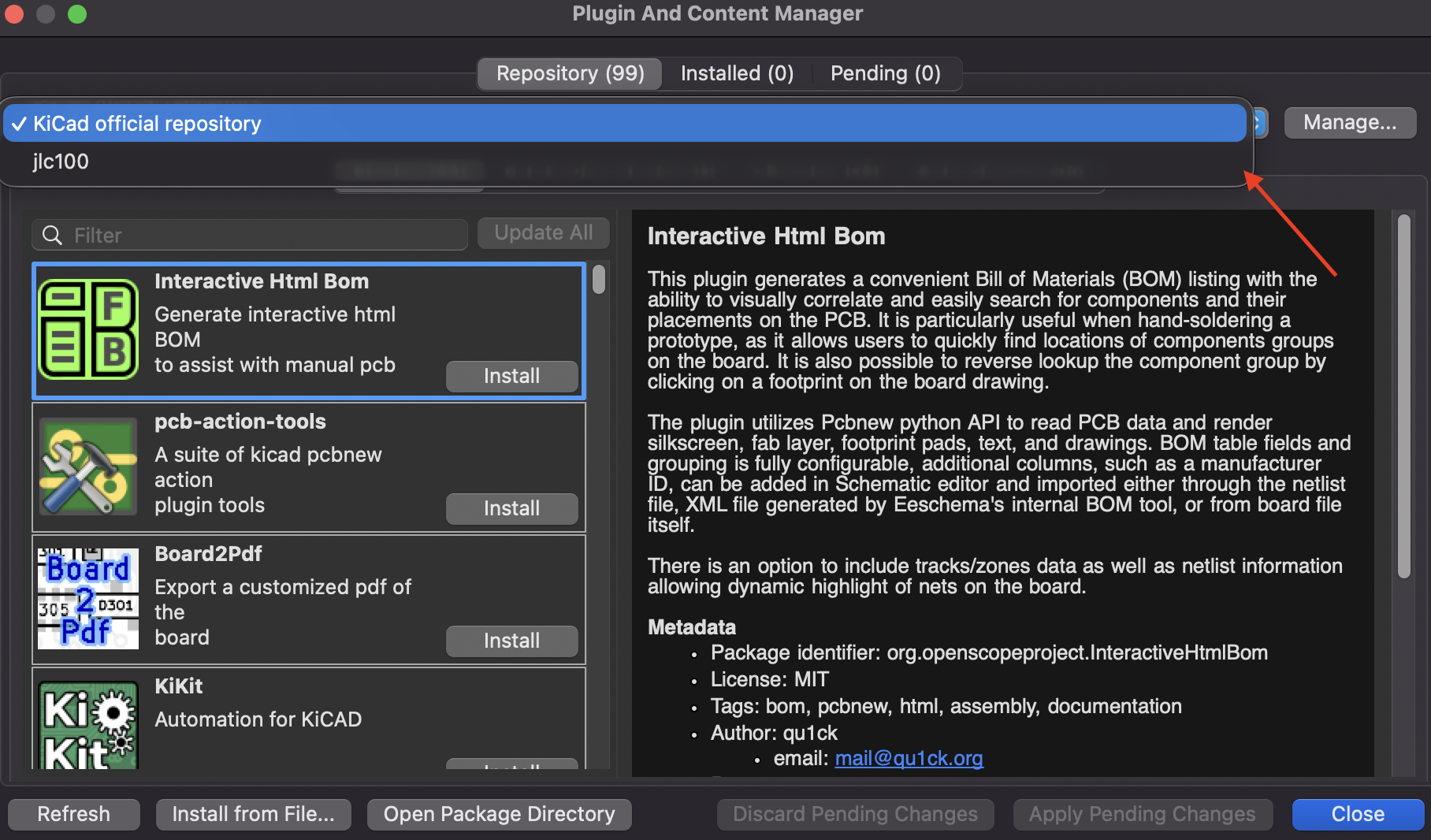

### Adding the PCM Repository to KiCad

To use your tscircuit components in KiCad:

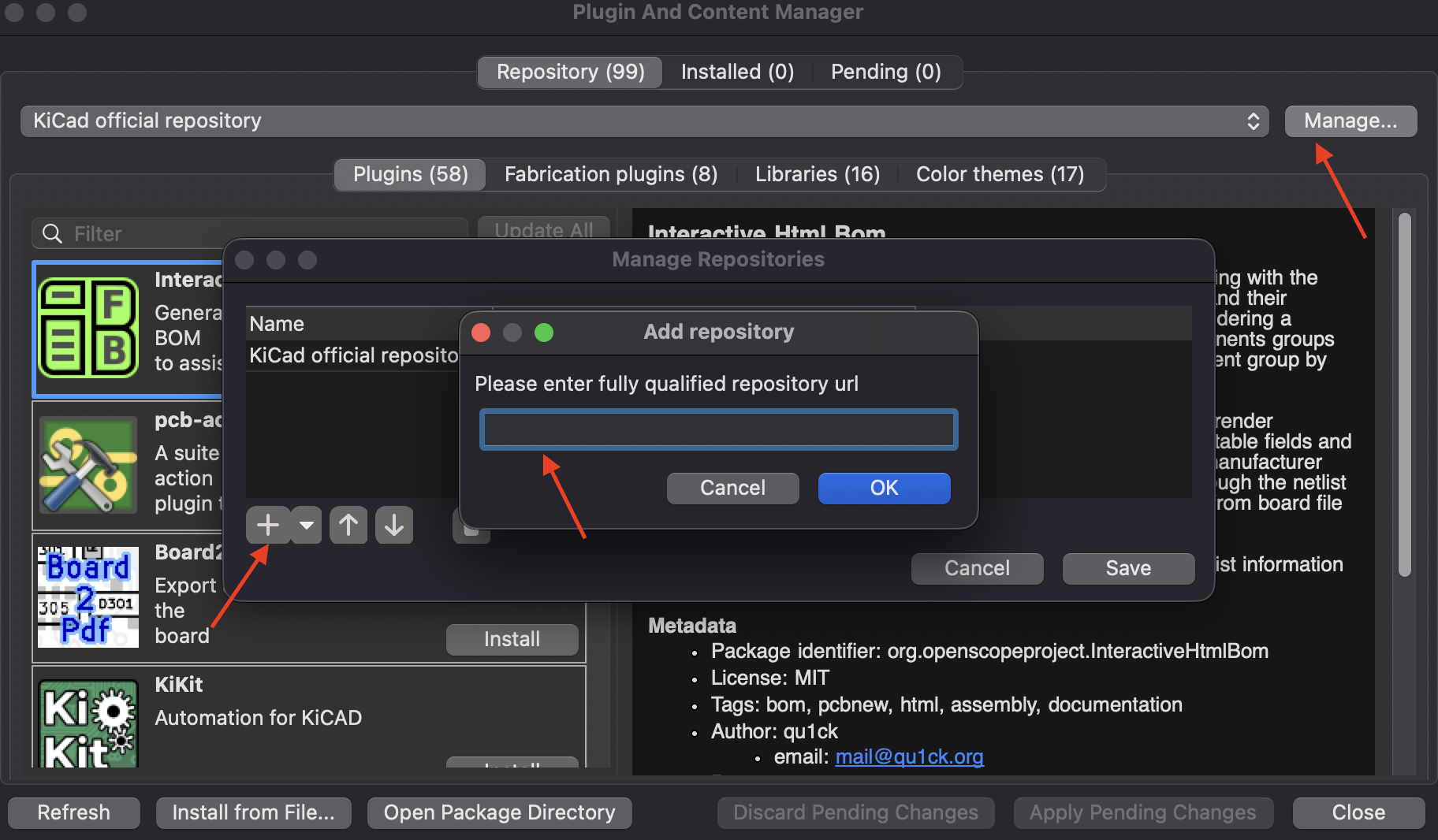

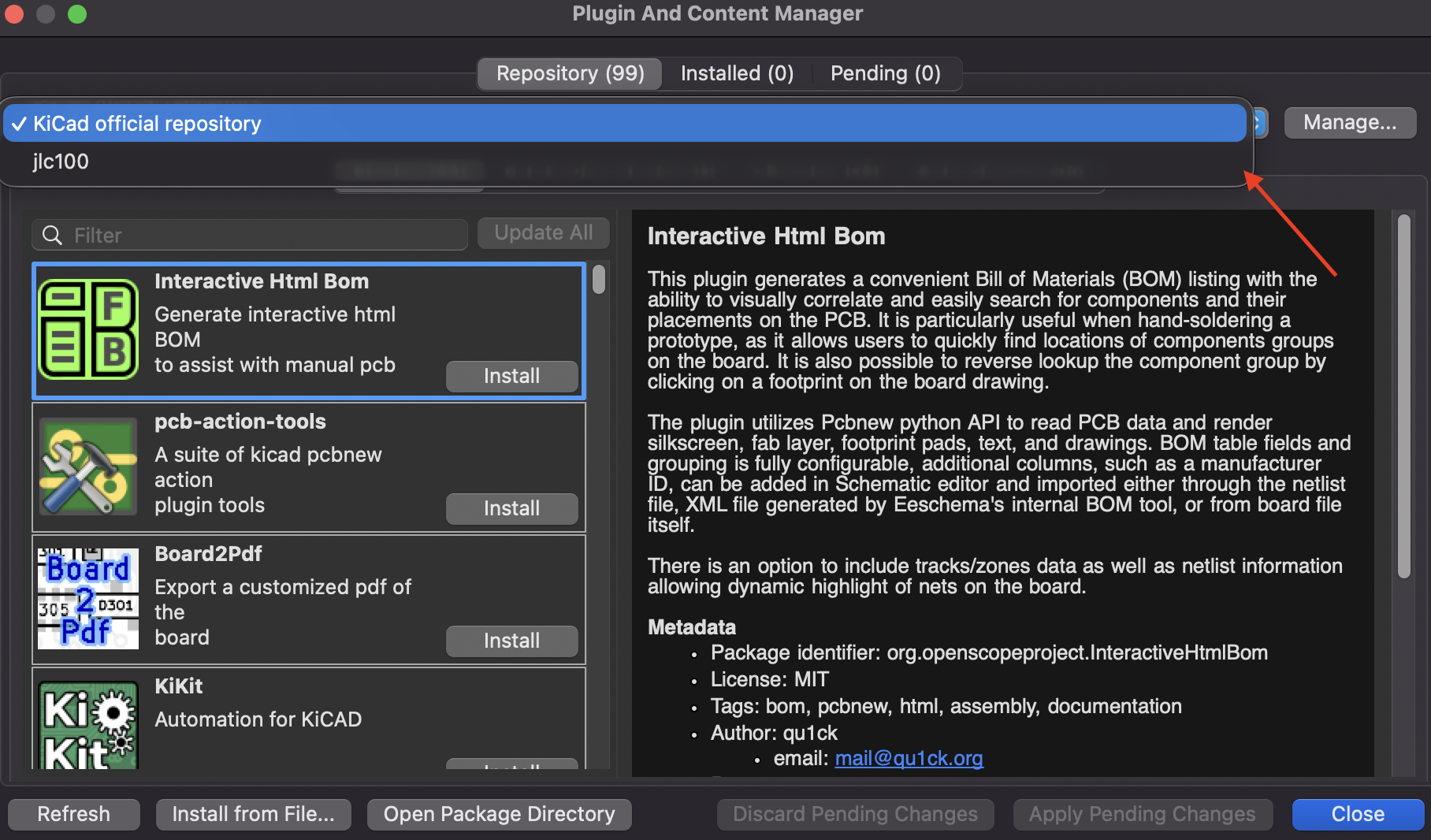

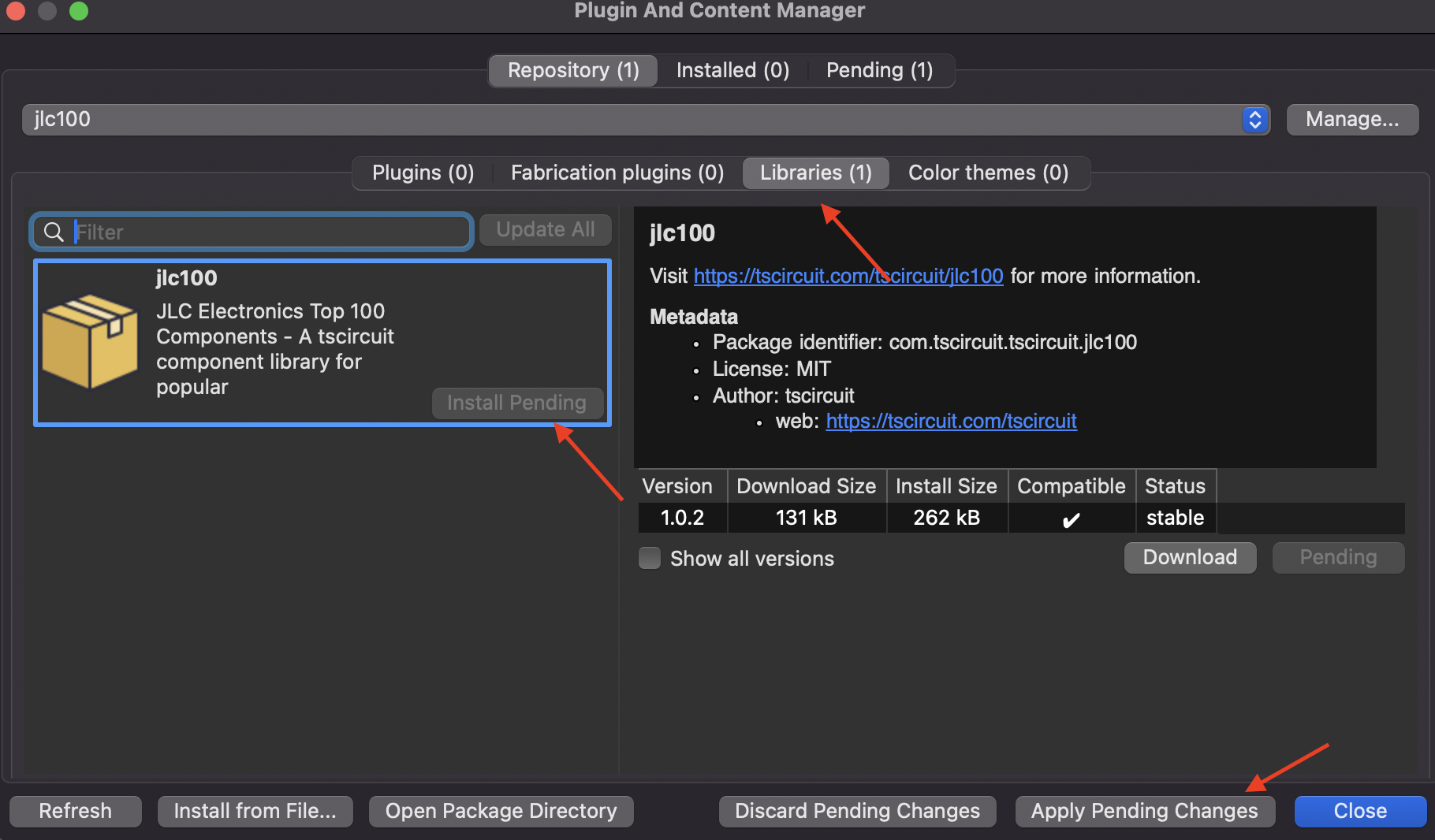

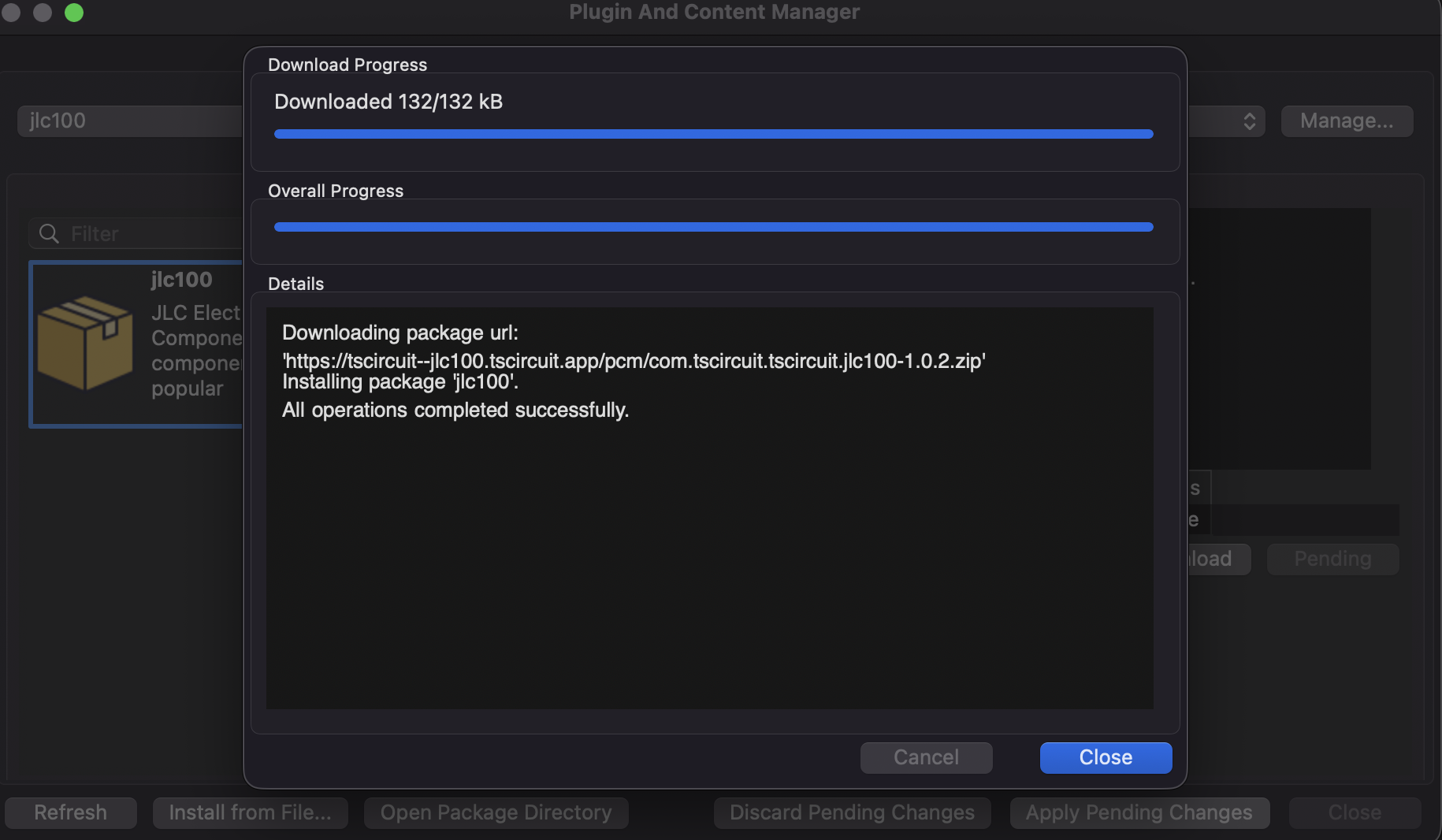

1. Open KiCad and go to **Plugin and Content Manager**

2. Click **Manage Repositories**

3. Click the **Add** button (plus icon)

4. Enter the PCM URL shown in your terminal (e.g., `http://localhost:3023/pcm/repository.json`)

5. Click **OK** to save

Once added, your tscircuit library will appear in KiCad's Plugin and Content

Manager. The library automatically updates as you make changes to your tscircuit

project, so you can iterate on your designs without needing to re-export.

---

title: tsci init

sidebar_position: 0

description: Initialize a new TSCircuit project

---

`tsci init` bootstraps a fresh project in the current directory. It creates the

basic files needed to start developing a board, including:

- `index.tsx` – your main circuit entrypoint

- `package.json` with the required dependencies

- `tsconfig.json`

- `.gitignore` and other configuration files

You can run the command interactively or pass `-y` to accept all defaults.

```bash

mkdir my-circuit

cd my-circuit

# Initialize with prompts

tsci init

# or skip prompts

tsci init -y

```

After initialization you will see a directory structure similar to the following:

```text

my-circuit/

├─ index.tsx

├─ package.json

├─ tsconfig.json

└─ tscircuit.config.json

```

import tsciInitImage from "../../static/img/tsci-init.png";

import ImageWithCaption from "../../src/components/ImageWithCaption";

Next, run `tsci dev` to start the development server and view your circuit in the

browser.

---

title: tsci login

description: Sign in to the tscircuit registry to enable publishing and cloud tools

sidebar_position: 1

---

`tsci login` allows you to login to the tscircuit registry. You don't need to

login to tscircuit to use any tools, but logging in does enable the following

great features:

- Cloud Autorouting (`autorouter="auto-cloud"`)

- Package Management (publishing and automatic bundling)

:::info

You don't need a tscircuit account to download and use other people's packages

:::

`tsci login` will take you to a login page where you'll sign in with Github.

After the login flow you'll have have token on your machine that authenticates

you to publish packages or use the cloud autorouter.

## Logout

To logout again, just run `tsci logout`

## Other Auth Functions

Run `tsci auth --help` to see other auth functions, such as printing your token

for use with the [Registry API](../web-apis/the-registry-api.md)

---

title: tsci push

sidebar_position: 2

description: |

tsci push uploads your package to the tscircuit registry for module re-use

---

tscircuit code, like React code, is distributed as a "package". `tsci push` uploads your package to the [tscircuit registry](https://tscircuit.com/trending) to enable sharing with your team.

After publishing, you can use the [tsci add](https://docs.tscircuit.com/command-line/tsci-add) command to install your package as part of a larger circuit.

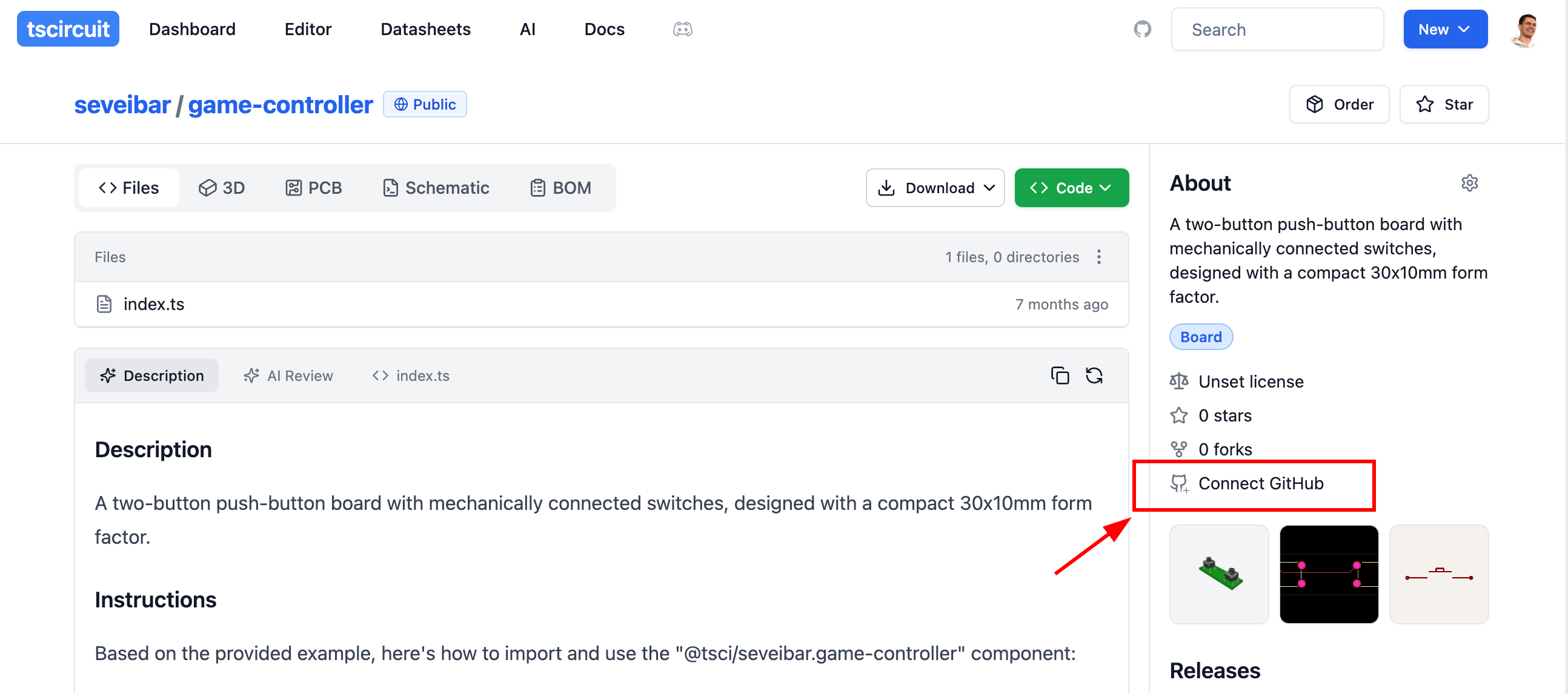

After running `tsci push` you can see your package on your tscircuit registry page. Packages default to private visibility, but you can change this from your registry page to enable sharing your package with the broader ecosystem.

import tsciPushImage from "../../static/img/tsci-push.png"

import registrySnippetImage from "../../static/img/registry-snippet.png"

import ImageWithCaption from "../../src/components/ImageWithCaption";

---

title: tsci search

description: Discover footprints and packages across the tscircuit ecosystem

---

`tsci search` finds footprints and packages from across the tscircuit ecosystem.

## Usage

```bash

$ tsci search resistor

Found 10 footprint(s) from KiCad:

1. Resistor_SMD/R_01005_0402Metric_Pad0.57x0.30mm_HandSolder

2. Resistor_SMD/R_01005_0402Metric

3. Resistor_SMD/R_0201_0603Metric_Pad0.64x0.40mm_HandSolder

4. Resistor_SMD/R_0201_0603Metric

5. Resistor_SMD/R_0402_1005Metric_Pad0.72x0.64mm_HandSolder

6. Resistor_SMD/R_0402_1005Metric

7. Resistor_SMD/R_0603_1608Metric_Pad0.98x0.95mm_HandSolder

8. Resistor_SMD/R_0603_1608Metric

9. Resistor_SMD/R_0612_1632Metric_Pad1.18x3.40mm_HandSolder

10. Resistor_SMD/R_0612_1632Metric

Found 11 package(s) in the tscircuit registry:

1. seveibar/usb-c-flashlight (vundefined) - Stars: 5 - A compact USB-C powered push button board with a red LED, utilizing a single current-limiting resistor for the LED indicator.

2. ArnavK-09/OPT4048DTSR (vundefined) - Stars: 3 - Sparkfun schematic with an 8-pin SOIC-8 IC (OPT4048) connected to a 3.3V power supply, ground, I2C bus lines (SCL, SDA), an address pin, an interrupt pin, plus a pull-up resistor and a decoupling capacitor.

...

```

Use any search term to discover related footprints or published projects.

---

title: tsci snapshot

description: Generate schematic and PCB snapshots for regression tests

---

`tsci snapshot` renders your boards to SVG images and compares them with saved snapshots.

## Usage

```bash

tsci snapshot [options]

```

### Options

- `-u, --update` – write new snapshots to disk.

- `--3d` – also generate 3D preview snapshots.

### Which files are snapped?

The command searches the current project for:

- the detected entrypoint (using the same logic as `tsci build`)

- any files matching `*.board.tsx` or `*.circuit.tsx`

This pattern allows standalone board files (ending in `.circuit.tsx`) to be tested alongside your main project.

### Snapshot location

Snapshots are stored next to each source file in a `__snapshots__` directory. For a file `test.board.tsx` you will see:

```

__snapshots__/test.board-pcb.snap.svg

__snapshots__/test.board-schematic.snap.svg

```

If `--3d` is specified, a `-3d.snap.svg` is also produced.

Running without `--update` verifies that the generated output matches the existing snapshots. Differences cause a non-zero exit code.

---

title: Bounties and Sponsorship

description: Understand how tscircuit bounties and contributor sponsorships are awarded

---

tscircuit has thousands of dollars (USD) of bounties opened every month in over

50 new weekly issues. We also automatically sponsor regular contributors

hundreds of dollars each based on their contributions. All of this activity is

tracked in the open-source

[contribution-tracker](https://github.com/tscircuit/contribution-tracker),

which powers [contributions.tscircuit.com](https://contributions.tscircuit.com)

and resets every Wednesday.

## How the contribution tracker works

- Every PR across the tscircuit GitHub org is scanned and summarized via an LLM

so we can consistently understand the scope of each change.

- The LLM classifies each diff/PR into attributes such as **🐳 Major**,

**🐙 Minor**, and **🐌 Tiny** impact levels and assigns a star rating that feeds

the weekly score shown on the sponsorship leaderboard.

- The resulting data is organized into the sections you see on the tracker—such

as Contributor Overview, PRs by Repository, and PRs by Contributor—so you can

quickly understand where impactful work is happening across the ecosystem.

- Historical exports, including weekly contribution overviews and AI-generated

monthly changelogs, are kept directly in the

[contribution-tracker repo](https://github.com/tscircuit/contribution-tracker)

if you want to dig deeper into past activity.

Many people follow the [bounties channel on discord](https://discord.com/channels/1233487248129921135/1301957862762872832) or our [bounty board](https://console.algora.io/org/tscircuit/bounties?status=open)

to find issues to contribute to, but **this is actually the hardest way to get bounties!**

:::tip

You can quickly find issues (with or without bounties) by [spinning the wheel of issues](https://issues.tscircuit.com/)

:::